-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

December 2, 2020

Triggo: Designing Next-Gen Transforming Cars with the Ansys Startup Program

Nobody likes sitting in traffic or searching for a parking spot. What if those time-consuming tasks could be eliminated? Say hello to the Triggo, a transforming electric vehicle that changes the geometry of its chassis depending on driving needs.

The vehicle was developed from scratch by a team of dedicated automotive and aeronautic engineers at Triggo, a small Polish startup that has increased its number of employees by 600% since being founded in 2015. Thanks to the Ansys Startup Program, the company will deploy its first pre-production prototypes in early 2021 prior to going into full production.

Triggo was designed to capitalize on the mobility as a service (MaaS) revolution, which is projected to generate nearly $100 billion globally by 2025. Triggo is engineered with a drive-by-wire steering system. In the future, Triggo will be summoned by a customer’s cellphone app, then autonomously drive to a pickup location where the user hops in and commutes to their destination.

Vehicle Wheels Engineered to Retract

Reaching speeds of 90 km/h (56 mph) in cruising mode, Triggo’s adaptive, foldable front suspension extends to 148 cm (39 in.) But when it encounters traffic, the magic really happens. Switching to maneuvering mode enables the driver to retract the wheels into the body, producing a maximum width of just 86 cm (slimmer than many motorcycles), letting it rapidly zip between cars and through traffic jams with ease.

The Triggo vehicle transforms from cruising mode (left) to maneuvering

mode (right) in just one second while driving.

And because it’s so slender, Triggo requires just one-fifth the width of a traditional parking space, helping the driver park nearly anywhere.

Overcoming Design Challenges with Simulation

The Ansys Startup Program helped Triggo’s engineering team overcome several key challenges, including visualizing the vehicle’s movement as it transforms from cruising mode to maneuvering mode in just one second. For example, as its wheels fold in, the dampers and springs assume different positions and the mass spreads to different places, delivering a completely different driving experience.

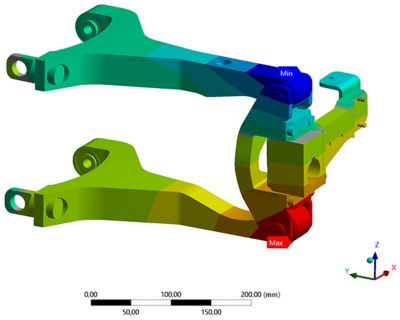

Ansys technologies also helped Triggo’s team create the vehicle’s steel frame, which was topologically optimized to give it a high torsional stiffness while keeping its overall mass low, a crucial parameter for the electric-powered vehicle, in terms of prolonging range per charge.

Triggo's wheels can be retracted to make it slimmer than many motorcycles.

“Thanks to the Ansys Startup Program, we leveraged Ansys Mechanical to precisely measure the durability of the frame and received a holistic view of the entire vehicle to ensure every component worked together seamlessly, said Michał Kowalewski, CEA Engineer at Triggo.

Harnessing Ansys Startup Program Technologies

Triggo engineers leveraged several Mechanical models on Ansys Workbench, conducting static structural analysis, linear buckling analysis and linear and non-linear dynamics analyses. Additionally, engineers used topology optimization analysis to understand the required modifications needed for achieving the desired stiffness and durability, reduce the overall mass and weight of every component, maximize the battery’s energy efficiency, and highlight any manufacturing process limitations.

Ansys Mechanical helped Triggo engineers conduct system

stiffness analysis, enabling them to measure component durability.

“The Ansys Startup Program helped our engineering team the most by giving access to the best CAE on the market at a very low price, especially in the early stage of development, when our team had extremely limited resources,” said Adam Kutyłowski, Head of public relations at Triggo. “This helped them visualize the Triggo’s design limitations and rapidly develop new solutions to radically improve the vehicle’s performance.”

After the numerical simulations were run, Ansys Viewer enabled the engineers to review the results.

“Creating the Triggo vehicle would have been impossible without the Ansys Startup Program and our engineers’ relationship with Ansys goes way back. In fact, many of our engineers recently graduated from the Warsaw University of Technology, where they trained to use Ansys simulations,” said Kutyłowski.

“When we began developing the Triggo car, our engineers knew Ansys technologies would prove instrumental for designing a safe, highly reliable vehicle and significantly reduce the need for creating many expensive prototypes.”

One of Triggo’s key goals is to meet the European New Car Assessment Program (NCAP) high safety standard. Ansys Mechanical played a pivotal role in helping engineers conduct numerical analysis and properly designing the vehicle’s composite body prior to testing, enabling it to satisfy stringent NCAP rollover safety requirements.

Triggo helps drivers avoid traffic jams and long commutes.

MESco, an Ansys Elite channel Partner in Poland, provides support and service to Triggo.

Check out the Ansys Startup Program web page for more details on how your company can participate.