-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Ansys博客

August 30, 2023

开发“全球最大的电池”

把海洋用作世界上最大的电池,这就是CorPower Ocean的业务。这家瑞典公司开发了一种利用波浪起伏能量的波浪能技术。他们通过浮标内的专利技术,将海洋波浪能转化为清洁可再生电能,为千家万户的家庭和企业供电。与风能或太阳能发电系统不同,CorPower Ocean浮标不会在太阳落山或风力减弱时停止发电。浮标昼夜在汹涌的海浪中漂浮,带来更加可靠、可预测的能源,有助于通过清洁电能平衡电网。

CorPower Ocean波浪能发电厂。图片来源:CorPower Ocean

与所有专为海上应用开发的技术一样,该技术的成功取决于其在变化莫测的恶劣条件下正常运行的能力。然而,作为一家锐意进取但预算十分有限的新兴公司,要构建工程师提议的每项技术或浮标设计变体的原型、将其运到海上进行测试,是难以实现、不可取的。那么,如何能以最具成本效益的方式确保设计在实际条件下仍然有效并可靠运行?CorPower Ocean工程师利用了Ansys仿真工具。

仿真汹涌的海浪

波浪能是世界上最大的待开发清洁能源之一。全球范围内,易于开发的潜在波浪能为500吉瓦(5亿千瓦),这一数字与当今水力发电能力相当,超过了当前核发电能力。CorPower Ocean的波浪能转换器被设计为固定在海底,一个CorPack浮标集群可产生10至20兆瓦的电能。多个CorPack集群可以被连接在一起,提供千兆级电能,所有这些集群共享一个公共输电基础设施。

The buoy is tethered to the seafloor via a patented anchoring technology. A cable links multiple buoys and passes clean electrical energy into the local grid. Image courtesy of CorPower Ocean

At the same time, much of the body of each 19-meter buoy sits like an iceberg beneath the surface of the ocean. Even from a nearby coast, you can hardly see the slender tops of the tear-shaped buoys. This makes the CorPower Ocean wave system much more attractive to coastal communities. These communities might not like big wind turbines blocking their view of the ocean from high above the water. Indeed, a wave farm of CorPower Ocean’s buoys configured to produce the same electrical output as a oceanic wind farm takes up only a third of the surface area required by such a wind farm and is virtually invisible from the shore.

But some of those seacoasts are not very friendly to any man-made object. The saline environment is corrosive, and storm surges can transform a sea that is relatively gentle one day to one buffeted by waves that can be tens of meters tall the next. Other wave generation technologies have failed because of the variability encountered in these extreme conditions, and the challenge of designing a system that is extremely effective in extracting power from the ocean, while surviving the extremes of 100-year storms, is why CorPower Ocean knew it needed to address these issues from the beginning.

“We use MetOcean data from the most energetic sites,” says Ho-Ann Chen, a Composite Design Engineer at CorPower Ocean, “including wave height, period and direction, as well as tides, currents, and more. These variables become inputs for proprietary ‘wave-to-wire’ model that CorPower Ocean uses to model expected design loads and energy outcomes from individual locations.”

Those inputs also help Chen and other engineers at CorPower Ocean test and refine the design of the buoys and the energy-generating technologies they house.

“We needed to design structures that are optimized for energy production, cost, and survival of extreme storms” says Javier Verdeguer, the Lead Composite Engineer at CorPower Ocean. For these tasks, Ansys Mechanical and Ansys Fluent provided powerful simulation support. The engineering teams used Mechanical and Fluent to model, test, and refine the physical size and shape of the buoys.

“We used simulation throughout the design phase,” Verdeguer continues. “We ran all kinds of simulations involving storms of differing strengths and wave-slamming events against the hulls of a buoy. We looked at simulations where giant waves washed over the buoys and left them submerged at different depths for a period of time. Did they buckle? Where were there structural weaknesses? We looked at different designs to see how they performed under a wide range of simulated stress loads, evaluated them for fatigue performance, and then used the results of those simulations to optimize the geometry of the buoys with those loads in mind.”

浮标通过专利锚固技术固定在海底。一根电缆连接多个浮标并将清洁电能输入当地电网。图片来源:CorPower Ocean

与此同时,每个19米长的浮标主体大部分像冰山一样,坐落在海面以下。即使从附近的海岸,也很难看到泪珠状浮标细长的顶部,因此CorPower海浪发电系统对沿海社区更具诱惑力。这些社区可能不喜欢大型风力机,因为其会阻挡他们眺望海面的视线。事实上,CorPower Ocean浮标的波浪发电场经过精心配置,电力输出与海洋风电场相同,其所占面积仅为这类风电场所需面积的三分之一,而且从岸上几乎看不到其身影。

但有些海岸,对任何人造物体都不友好。这类海岸的盐化环境具有腐蚀性,而且平时风和丽日的平静海面,只要遇到风暴潮,就会变得波涛汹涌,浪高数十米。这些极端条件下的可变性,导致了其它海浪发电技术的失败,而且,设计一款既能通过海洋高效发电,同时又能经受100年风暴极端条件考验的系统,本身就充满挑战,因此,CorPower Ocean深知必须从一开始就解决这些问题。

CorPower Ocean复合材料设计工程师Ho-Ann Chen提道:“我们使用发电量最高的发电场的MetOcean数据,其中包括浪高、周期和方向,以及潮汐和洋流等。这些变量将成为‘波浪能转换’专有模型的输入数据,CorPower Ocean使用‘波浪能转换’专有模型针对各个位置的预期设计负载和能量产出进行建模。”

此外,这些输入数据还有助于Chen以及CorPower Ocean的其他工程师测试并优化浮标设计以及其所承载的发电技术。

CorPower Ocean首席复合材料工程师Javier Verdeguer表示:“我们需要设计针对发电、成本以及经受极端风暴进行优化的结构。”针对这些任务,Ansys Mechanical和Ansys Fluent在仿真方面提供了强大的支持。工程设计团队使用Mechanical和Fluent对浮标的物理尺寸和形状进行建模、测试和优化。

“我们在整个设计阶段都使用了仿真技术,”Verdeguer继续道,“我们执行了各种仿真,其中包括不同强度的风暴以及海浪拍击浮标外壳的情况等。我们在仿真中查看巨浪冲刷浮标以及浮标在不同深度淹没一段时间的情况。它们变形了吗?结构上的不足在哪里?我们不仅查看不同设计,了解了它们在各种仿真应力负载下的性能,而且还评估了它们的疲劳性能,然后利用这些仿真的结果在充分考虑这些负载的情况下,优化了浮标的几何结构。”

CorPower Ocean设计人员甚至还通过Ansys Composite PrepPost仿真确定细丝材料和缠绕模式的最佳组合,其将用于包裹建造浮标外壳的复合材料。他们使用实验设计方法进行优化研究,以确定以不同角度缠绕、哪种细丝组合会带来最轻、最坚固的外壳。然后,他们将这些优化规范传递给在CorPower Ocean移动工厂系统中控制细丝缠绕系统的软件,其可帮助CorPower Ocean在将要部署浮标的位置构建复合材料外壳,进而无需将浮标从通常很遥远的制造场所运往其安装地。

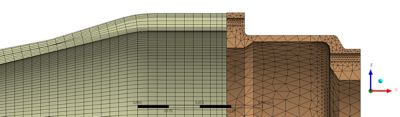

CorPower Ocean浮标中复合接头的仿真网状结构。图片来源:CorPower Ocean

海浪发电告别大规模原型设计时代

虽然CorPower Ocean已经在海上制造并运行了一款半规模设备,并且正在葡萄牙阿古卡杜拉进行其全尺寸概念验证部署,但该公司已能够通过仿真技术来避免每次设计改进时都构建并测试原型。涉及几个关键原型的早期物理测试有效验证了仿真过程中预测的结果,因此工程设计团队非常确信,仿真显示结果可以预测在真实场景中部署实际会出现的情况。最终,CorPower Ocean在降低成本的同时,加速了设计:工程师不仅不需要等待原型的构建、交付及下水测试,而且还可在几分钟或几小时内看到仿真结果。这不但可加速交付优化的可供客户使用的产品,而且还可确保CorPower Ocean能够以客户可以承受的合理价格提供产品,即使在计划进行超大规模的部署时也不例外。

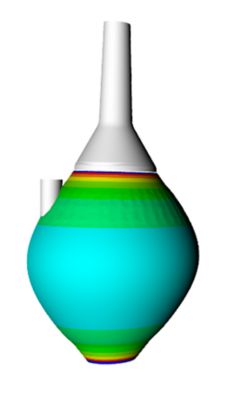

ACP复合建模缠绕模式映射。在这里,CorPower Ocean可以准确地定义其缠绕产品的厚度。

当浮标随海浪起伏时,浮标内承载的技术会将波浪能转换成旋转能,进行发电。图片来源:CorPower Ocean

Verdeguer指出:“我们最终将构建复杂的大型发电系统。在设计阶段发现问题、优化结果的能力越强,降低项目风险的效率就越高。”

随着整个世界竞相采用清洁可再生能源(尤其是能够全天候、可靠地生产绿色环保能源的方式),在降低项目风险的同时加速设计,无疑益处良多。