-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

January 19, 2021

Simulation Helps Nevomo Innovate From Maglev to Hyperloop Technology

Although travel has been significantly curtailed during the pandemic, it remains a fundamental part of modern life. Whether getting from point A to point B means a quick trip around town or an extended journey across the planet, today’s travel experience can be complex and energy intense. With increasing pressure to lower emissions, figuring out how to make new transportation technology as “green” as possible — while also increasing travel speed and maintaining safety — is a priority.

Among those leading the charge is Polish startup Nevomo. The company, whose founders were finalists in the 2017 SpaceX Hyperloop Pod Competition, is developing a new generation of high-speed railways based on magnetic levitation (called mag rail), linear motor and autonomous control systems. Their hyperloop-inspired mag rail train will run on existing railway tracks upgraded to accommodate high-speed travel, with no need to build new infrastructure.

Hyperloop Technology Meets the Need for Speed

Among other differences, hyperloop rail doesn’t run on wheels like a conventional train. Instead, the compartments — called podcars or personal rapid transit (PRT) — are designed to essentially float on something akin to air skis using passive maglev technology to reduce friction. With eventual speeds up to 1,200 kph (745 mph), mag rail trains will be faster than airplane travel. Yet, because mag rail trains will run on electricity, their carbon footprint is expected to be insignificant.

Nevomo is rolling out its system in three phases. Each new phase promises higher speeds than the previous one:

- A passive maglev train — or mag rail — will operate on upgraded, existing rail lines at speeds up to 550 kph (340 mph). This is about twice as fast as trains operating on conventional rail lines and the same as high-speed rail.

- Adding special vacuum covers will transform the mag rail technology to hyper-rail with a top speed of 600 kph (373 mph).

- Hyperloop, which will run on a dedicated track, could push speeds up to 1,200 kph (745 mph).

Simulation Enhances Mag Rail Brake Performance

Companies worldwide are working on hyperloop vehicles. With competition so fierce and the project so revolutionary, getting to market first requires finding satisfactory solutions to complex issues and doing it efficiently.

Permanent magnet assembly used for levitation system

in Nevomo's demonstration vehicle

Using Ansys simulation in the early design phase enabled Nevomo engineers to quickly understand how passive magnetic levitation, electromagnetic brakes and linear motors will work under various conditions. Ultimately, simulation helped Nevomo avoid errors and achieve a number of design milestones in less time.

For example, simulating the mag rail’s electromagnetic brakes enhanced the development process by reducing computation time and enabling verification of multiple design variations.

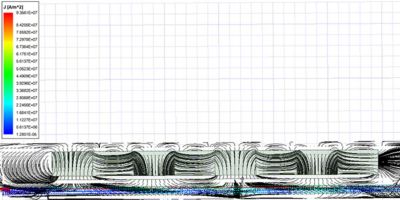

A time step from simulation of Nevomo's permanent magnet

levitation system, with flux lines and current density plots

The electromagnetic brakes are based on NdFeB (neodymium-iron-boron or "neo") permanent magnets — a rare earth magnet that can meet high-density energy requirements. To optimize the strength of the magnetic field, Nevomo simulated various magnet arrays and magnetization directions. Engineers also used Ansys distributed solve options (DSO) and high-performance computing (HPC) technology to speed up solution time over hundreds of 3D simulations.

Getting to the Future First

Nevomo's work on mag rail technology includes designing a permanent magnet linear synchronous motor for contactless propulsion. Simulation helps reduce the number of physical prototypes, saving money as well as time. The company also plans to use Ansys software to analyze antenna design and optimize printed circuit board shielding from electromagnetic radiation.

Working on life-changing technology requires a unique approach and robust tools. With computer simulation, Nevomo is pioneering hyperloop invention and bringing the world into the future, faster.

Symkom, an Ansys Channel Partner in Poland, provides service and support to Nevomo. Symkom provides its customers with computer-aided engineering (CAE) solutions in the areas of fluids, mechanical, electromagnetics and coupled analysis.

To learn more about Ansys solutions for Rail Industry please register for the Rail Industry Webinar Series.