-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

June 3, 2022

Simulating Safe Hydrogen Tank Design for Electric-Powered Aircraft

Ever since the fiery destruction of the hydrogen-filled Hindenburg rigid airship on May 6, 1937, engineers have been cautious about using highly explosive hydrogen for buoyancy, as in the Hindenburg’s case, or as an energy source. Of course, the 16 hydrogen-filled cells of the Hindenburg, which were made of two layers of cotton separated by a gelatin film, were not the safest of storage containers for such a flammable gas.

Modern aerospace companies are once again investigating the use of hydrogen, this time in fuel cells to power their turbine engines electrically as part of their environmental and sustainability efforts. Fuel cells combine hydrogen with oxygen to generate energy and form water, the only waste product of the process.

This time around, aerospace companies are investigating composite gas tanks to store the hydrogen for greater safety. Engineers simulate the design, build, and operation of these composite tanks, which store liquified hydrogen at pressures up to 700 bars and cryogenic temperatures of -253 °C. These conditions are necessary to keep the volume of the hydrogen within reasonable limits for an aircraft. Hydrogen is more energy dense, volumetrically, than jet fuel, but it also takes more space. Approximately 3,000 liters of gaseous hydrogen contain the same amount of energy as one liter of kerosene, at standard temperature and pressure. So, pressurizing the hydrogen and cooling it to form a liquid keeps the volume down, but these pressure and temperature conditions require strong, composite-based tanks.

Composite hydrogen tank design is a multiphysics and multiscale problem. Ansys provides all simulation solutions in one platform, with an end-to-end composite hydrogen tank design workflow that incorporates Ansys SpaceClaim Direct Modeler, Ansys Material Designer, Ansys Mechanical, Ansys Composite PrePost, and Ansys LS-DYNA software.

Two Main Concerns: Domes Layup Modeling and Composite Cracking

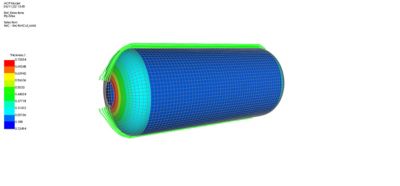

During the design and production phases of composite hydrogen tanks, the biggest challenge is making the transition from the cylindrical body of the hydrogen tank to the dome-shaped caps on each end. The majority of manufacturers use the filament winding method to produce composite hydrogen tanks. The challenge is that the composite layup pattern changes at the transition from the cylinder to the dome. How do you model the composite in the transition zone correctly? Composite PrePost can help manage this complex transition region.

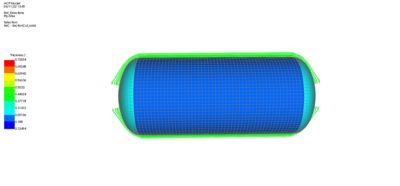

Ansys Composite PrepPost (ACP) enables user to accurately model the composite thickness build up in the tank and provide different options to visualize it.

When the fuel cell is operating, crack initiation and propagation leading to leakage of hydrogen is the main concern under cryogenic conditions. Cracking could occur within a composite laminate due to differences in the coefficient of thermal expansion of the fiber and matrix phases. Physical stressors during operation and maintenance and thermal stressors during tank refilling are other possible sources of crack initiation.

If a crack causes a leak in the hydrogen tank on an aircraft, you want to ensure that the hydrogen travels directly up in the air so it can be vented. If the hydrogen catches fire, mitigation solutions must be in place to confine the fire to a small volume.

Another consideration is manufacturing the tank using materials that will not allow a crack to continue propagating once initiated. Controlling crack propagation limits the size of the damage and keeps hydrogen leakage to a minimum.

Ansys’ End-to-End Solution

To mitigate these concerns, engineers start with Ansys simulations from the early design stage through to the testing, certification, and operation stages.

Engineers use SpaceClaim Direct Modeler for geometry design of the hydrogen tank. They can explore various geometries quickly and perform parametric studies to arrive at an optimal geometry.

With Material Designer, engineers can obtain homogenized thermal and elastic material properties accounting for the real microstructures of composite materials. Choosing an optimal material system can be essential in controlling crack initiation and propagation while maximizing weight savings.

Users can use build-in composite failure criteria to evaluate the composite hydrogen tank design, whether they want to evaluate the whole hydrogen tank, or just side wall or dome.

Composite PrePost software helps to model the composite layup from the cylindrical section of the tank to the domes using ply-based modeling and a “model as you build it” process. This process eliminates the need of interpreting how laminates are built up in the workshop; instead, it relies on intuitive modeling in this transition region. The Python-based scripting capability also enables engineers to incorporate their own algorithm based on intuition and observation to predict the winding angle and composite thickness in the transition region of a hydrogen tank.

Finally, to account for the hydrogen tank manufacturing process, Composite Cure simulation enables engineers to:

- Simulate the thermal-chemical reaction and predict the development of residual stresses and process-induced distortion during composite manufacturing

- Optimize the curing process (exothermic peak) and design the heating and cooling systems

- Compensate the tooling geometry to meet the geometrical tolerances or to design the assembly process resulting in the minimal built-in stresses

- Evaluate the impact of residual stress on the composite hydrogen tank

For optimal manufacturing of composite structures, CADWind, CADFil, and Mikrosam all have specialized composite winding tools that simplify the modeling, increase its accuracy, and generate the machine code. Since these tools support the Hierarchical Data Format version 5 (HDF5) composite CAE interface, the data transfer to Ansys Workbench and Composite PrePost is seamless, enabling engineers to use all the composite features in these Ansys software solutions.

Certifying Composite Hydrogen Tank Design Using Ansys Multiphysics Simulation Solutions

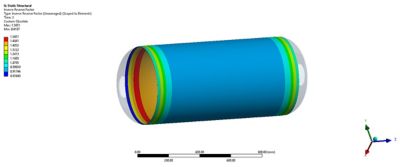

Once manufactured, the composite hydrogen tank can be certified for use through multiscale analysis of the cryogenic temperature effect. Matrix microcracking is a major concern under cryogenic temperature due to CTE mismatch and thermal cycling. It can be studied using multiscale and multiphysics Ansys simulations for:

- Material selection, data management and sharing

- Advanced matrix cracking criteria capability at a ply level (macro scale)

- Detailed analysis at the constituent level (micro scale)

- Leakage of hydrogen through crack channels

In addition, due to the unique nature of composite hydrogen tanks, delamination between different composite layers or different hydrogen tank parts is of great concern, especially for a multiwall tank design. The analysis of delamination can be performed using the fracture mechanics feature of Mechanical. Moreover, the state-of-art, built-in composite sandwich failure criteria in Mechanical and Composite PrePost enables engineers to analyze sandwich structural failure in a hydrogen tank under any service conditions.

Finally, composite hydrogen tank design must be certified according to standards. Virtual testing can help identify any potential risks earlier and investigate more scenarios before proceeding to certification testing. Progressive failure analysis can be performed using Mechanical and Composite PrePost. LS-DYNA can be used to simulate dynamic events like penetration and impact.

From the initial geometry creation step to the choice of materials, composite layout and curing, and certification, Ansys offers a one-stop platform for all aspects of designing hydrogen tanks for fuel cells to power all-electric aircraft.

To learn more about how aerospace engineers are overcoming the industry’s biggest challenges using Ansys software, view the Ansys Aerospace & Defense Webinar Series Aerospace & Defense Webinar Series.