-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

September 5, 2022

Scrapping Errors, Not Materials, with Simulation

Additive manufacturing (AM) is promising to be one of the biggest trends in sustainable manufacturing. New design practices like topology optimization result in much lighter optimized parts, which translates, for example, into lighter vehicles and greater fuel efficiency. During the 3D printing process, a part is created through the melting, binding, or fusing of a prescribed amount of material to support efforts toward a zero-waste environment. That’s not to say that 3D printing isn’t somewhat wasteful — printing shapes requires supports or structures that prevent deformation of a part during the printing process, resulting in a nominal amount of discarded material. But what happens in the case of failed prints?

Engineers can potentially scrap a significant number of parts and material to realize success during the design phase. Addressing errors often comes only after a failed part is identified late in the manufacturing process, along with the realization that continuing to print it is not an option. Additive manufacturing design methodologies may still be unfamiliar to most manufacturers, and relying on a trial-and-error approach to printing is impractical. Using Ansys software enables Combitech, an independent consulting company operating primarily in the Nordic region, to help their customers identify printing process issues that lead to failed prints of parts through simulation.

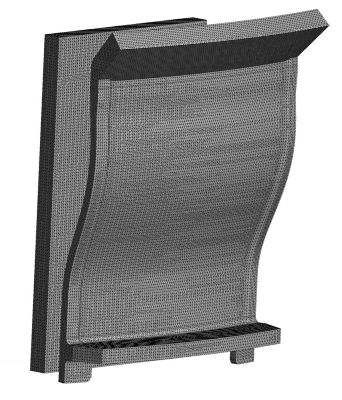

3D-printed demonstrator showing a tetrahedral mesh used for simulation of printing with the selective laser melting (SLM) method.

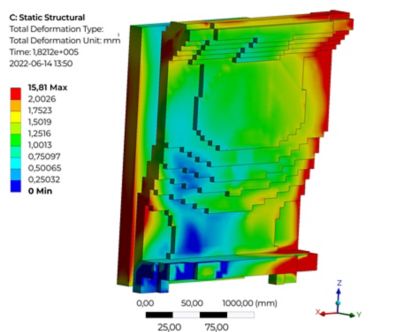

Simulation of static structural deformation after printing (i.e., after the removal of base plate and support structure)

Note: All simulation images in this article are from a research project sponsored by Vinnova's strategic innovation program (SIP), Production2030.

“We do the design work and simulate the production process at the part level,” says Tomas Sjödin, Head of Computer-Aided Engineering (CAE) and Analysis at Combitech. “For some customers, we only do the design work, and for other customers, we only do the simulation work of the production process. In other products we simulate the performance of the actual part itself, considering variables such as stiffness, fatigue, or strength.”

Drawing the Line Between Success and Failure

The idea to simulate production emerged from Combitech’s well-established working methods for sheet metal design verification, which involves sheet metal forming simulations. In addition to achieving a final product design, the methodology ensures that a product meets (and can be successfully manufactured in consideration of) customer requirements. Similarly, Combitech increased their activity within AM to streamline production for their customers. They initially wanted to be able to simulate an actual production cycle in the 3D printer to identify any issues during the printing process that led to failure. Together with Ansys, Combitech has carried out a number of projects to strengthen their competence in this area.

“Among our customers we see an increased use of 3D printing, both to save time and increase performance,” says Sjödin. “I come from the automotive industry and have been working a lot with body-in-white and sheet metal parts. For every single stamped automotive part manufactured, there’s a sheet metal stamping simulation of it before it’s produced, with no exceptions. This is to find and solve every issue before tools are ordered. We’re using the same strategy for 3D printing — before every part is sent to the printer, the process should be simulated to avoid print failure before production begins.”

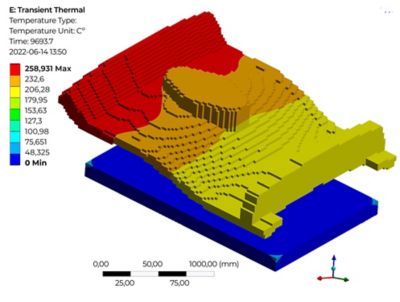

Transient thermal distribution of build part with the support structure and base plate for printing with the selective laser melting (SLM) method

When Accuracy Comes Down to a Fraction of a Millimeter

Using Ansys simulation solutions, Combitech has carried out a research project and two industrial projects in the defense industry. One of these projects required the use of selective laser melting (SLM), a form of AM that requires a high-power-density laser to melt and blend metallic powders together. This method was used on a part that included cooling channels to maintain specific mechanical properties and cool down electronics. Each cooling channel was measured down to 1 millimeter in diameter. Another requirement was that the surface should be flat down to 0.1 millimeter, ruling out milling as an option after printing.

The big challenge was achieving a detailed geometry that required a very fine mesh with long simulation times. In this scenario, Sjödin’s team wanted to see if Ansys Additive Suite could handle these high demands for accuracy. The overall goal was to implement changes to the geometry to achieve less distortion and meet the demand for the final geometry in a part with a very flat surface. Initially, this was a challenge for the customer — the first part they printed had a 1-millimeter surface deviation.

Using several tools in Additive Suite, the geometry was imported as STEP files and machine data was collected from the printer operator. Afterward, the team compared the simulation results with scanned data. Additive Suite’s integration capabilities were critical to Combitech’s overall success, enabling them to seamlessly import part geometry from STEP files for analysis. They also used their own scripts to compare scanned data from real parts with the simulations results, which helped them identify the causes of printing failures and arrive at a different solution for their customers.

Pre- and post-processing were done on engineering laptops in Windows; however, all design analyses were done on the Linux cluster with the appropriate number of CPUs. Due to the detailed geometry, engineers had to use a very fine mesh requiring long simulation times to achieve less distortion and meet customer requirements for the final geometry.

3D printed demonstrator using the powder-based laser metal deposition (LMD-P) method, showing transient thermal distribution after printing.

Additive Suite Reduces Customer Costs

Sjödin’s team also achieved success using Additive Suite for a smaller wire arc additive manufacturing (WAAM) project that involved laser metal deposition (LMD) — a direct energy deposition technique that is often used to 3D print metallic parts or add features to an existing metallic structure. During this process, a high-power laser is used to melt a metal surface while simultaneously depositing a metal powder or wire. Together with the customer, the team wanted to investigate the possibility of simulating the WAAM process involving a smaller product and a different printing method than what was previously used. With help from Additive Suite, the team managed to capture the overall phenomena and gain confidence in the method, results, tools, and timing required for the manufacture of a slightly different application.

“The results are very promising for Ansys Additive Suite in capturing physical phenomena that occur in reality,” says Sjödin. “I am convinced that simulations of the manufacturing process for AM will become standard work in the future, in the same way as simulation of sheet metal forming is today. By using Ansys simulations, we can reduce the number of failed parts and can correct a design before it costs our customers more time and money in 3D printing.”

Ansys’ tools, including Additive Suite, have dramatically improved overall part quality while speeding up the development process for Combitech customers. Using these tools, Combitech will continue to set new quality standards for production with simulation that make for lighter, low-waste solutions for aerospace, medical, transportation, energy, consumer products, and more.