-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

September 24, 2018

How to Prepare for Engineering Jobs in Simulation

Simulation is ubiquitous throughout industry, but it wasn’t always that way. What started as a tool for the aerospace and automotive sectors is now spawning an engineering job everywhere.

“You can get an engineering job simulating hair dryers, refrigerators even surgical equipment. It’s really universal,” says Gilles Eggenspieler, Academic Program sales director at Ansys.

Learning simulation is a great way

to get ahead

in the engineering job search.

“Companies tell us that they look for two things in the engineers they hire,” adds Eggenspieler. “Did they build anything, and do they have any special skills?”

Many graduates and young engineering professionals have skills similar to their peers. This isn’t surprising as engineering curricula are very similar from college to college. But these colleges tend not to teach simulation.

“Universities know the value of simulation for research and often teach simulation in graduate schools,” says Eggenspieler. “But not all use simulation in a pervasive manner in their engineering undergrad curriculum. Simulation can be used in capstone projects and many engineering classes.

“Nonetheless, many students learn simulation thanks to online learning tools, webinars and free student downloads,” adds Eggenspieler. “When adding simulation skills to their resumes, they already are a step ahead in finding an engineering job.”

Simulation Basics to Land Your Dream Engineering Job

So, what are the simulation basics engineers should know before entering the workforce.

First there are many types of simulation software.

Students looking to place an antenna on a drone need to learn electromagnetic simulation software.

As for students working to design a car for a competition, they need to make the parts as light as possible while maintaining structural integrity. That will require finite element analysis (FEA).

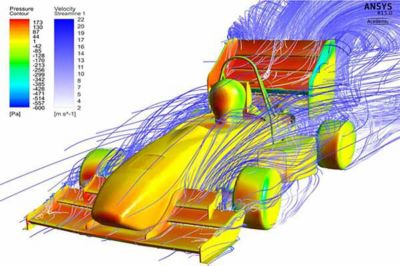

Students might also want to ensure their car is aerodynamic. That will require computational fluid dynamics (CFD) software.

CFD analysis to optimize the aerodynamics of a race car.

Many of these simulation techniques can also be linked together in multiphysics problems where the results of one simulation feed into another linearly or iteratively.

Try to learn which parts of the design should be simulated and what type of simulation software you need to model the appropriate physics. You will also need to learn which assumptions need to be made for the simulation to run efficiently.

When working on a multiphysics problem, Eggenspieler suggests that you don’t start simulating everything at once. Concentrate on simulating one physics at a time and work your way up. This will make it easier to fix any bugs that might come up in the model.

“In the meantime, you should learn about simulation terminology,” says Eggenspieler. “This allows students to learn simulation, demonstrate their skills and be able to share their results with both engineers and simulation experts.

“Most importantly, you need to learn how to interpret the results of the simulation,” stresses Eggenspieler. “Do your results make sense or is something wrong with the simulation like a typo in the boundary condition? What is the simulation teaching you? How can you use the results to improve your design? Can you perform more simulations to iterate toward a new design?”

How to Learn Simulation to Land an Engineering Career

Now the question is where do you gain a basic understanding of simulation?

“Where do you start? That depends on your interests,” says Eggenspieler. “Some engineers specialize in one topic — like an electrical engineer who is an expert in electromagnetic simulations but has only basic knowledge of structural simulations. Other engineers will broaden their horizons and specialize in simulating multiphysics applications.”

There are a lot of options online to learn simulation

A great way to learn simulation is by jumping into it. There are many courses, training videos and best practices online. You can access them from the Ansys Student Community.

“Students should use simulation in conjunction with a project they have, like a research project, student team or capstone project,” suggest Eggenspieler. “Use what you have to build and apply the simulation, so you have real world experience solving problems. You can then relate your simulation results to what you designed and iterate further to optimize the design.

“Every company wants makers,” adds Eggenspieler. “I talked to an aerospace company recently that only hires people who build stuff. They said hiring people from classes only was something you did in the year 2000, it’s very theoretical. And to build stuff optimally you need simulation.”

To help get your feel wet with simulation, check out a live series of free online webinars offered by Ansys. To sign up, follow these links: