-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

May 1, 2019

Pervasive Simulation Can Help Design Wind Turbines and Other Renewable Energy Technologies

The global renewable energy market is expected to grow at a 13.1% annual compound rate from 2018 through 2024, according to Envision Intelligence. As a result, companies are searching for ways to keep up with competitors aiming for that market growth.

Pervasive simulation enables companies to iterate and innovate every aspect of a design throughout its life cycle. Therefore, simulation is the best way for these companies to differentiate themselves from the pack and position themselves to absorb that market growth.

WEG is a Brazilian company looking to take advantage of the growth in the energy sector. It designs and manufactures wind turbines, turbogenerators and hydrogenerators. WEG uses Ansys pervasive simulation to assess the structural, electromagnetic, thermal and fluid performance of all of its products. The company has found that pervasive simulation empowers it to produce cutting-edge products while meeting demanding schedules and cost constraints.

WEG uses pervasive simulation to optimize the performance of its wind turbines and other renewable energy technologies.

WEG Uses Pervasive Simulation to Double a Wind Turbine’s Power Output

WEG engineers are developing a 4 MW direct-drive wind turbine with high-efficiency and low-maintenance requirements. By almost doubling the output of its current 2.1 MW platform, WEG hopes its new design will keep up with increasing demands.

The engineers use a variety of pervasive simulation tools to test and develop its designs throughout their life cycle, including:

- Ansys Mechanical

- Ansys Maxwell

- Ansys DesignXplorer

The increased power output involved in doubling the performance of a wind turbine causes high dynamic loading on the structural components. WEG engineers use Mechanical to evaluate the various load cases throughout the structure.

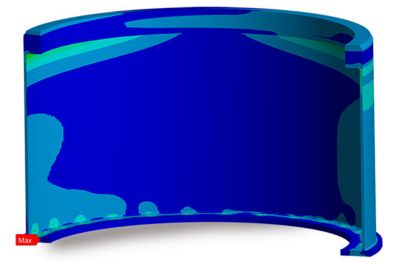

For instance, the nacelle tower-top adapter, which sits on top of the concrete tower and bears the weight of the turbine blades mounted on its front, must withstand extreme loads while avoiding plastic deformation and slippage. Engineers use structural simulation to evaluate stresses at the neck and at welding points. To complete their fatigue failure analysis, engineers use Ansys nCode DesignLife.

Critical welding spots throughout the structure are potential regions of structural weakness. Using Mechanical and DesignXplorer, WEG engineers evaluate these spots to ensure they can withstand the largest loads they would experience..

WEG uses simulation to ensure a wind turbine’s neck and welding points can withstand the loads created by the weight of the turbine blades.

Evaluating the Electromagnetic Performance of Wind Turbines

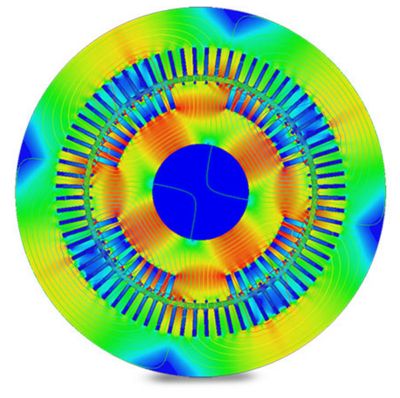

WEG engineers use Maxwell to simulate the low-frequency electromagnetic fields produced by the turbine during operation. These wind turbine simulations evaluate torque, induced voltage, losses and magnetic core saturation.

Minimizing harmonic currents between the generator and the power converter is critical for safe and optimal wind turbine performance. To maintain low, total harmonic distortion, engineers use Maxwell simulations to analyze magnet positioning, determine the generated voltage and assess the harmonic spectrum.

Pervasive simulation has made its way into every aspect of the design of WEG’s wind turbines. The same can be said about the other products made by WEG such as its turbogenerators and hydrogenerators.

Turbogenerators and hydrogenerators require some additional simulations, to assess their fluid flow. Learn more about wind turbine simulation, from embedded software to predictive maintenance.

Maxwell simulation is used to optimize the cylindrical pole generator of a wind turbine.