-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

August 13, 2020

Overcome Automotive Electronics Reliability Engineering Challenges

The basic structure of an automobile hasn’t changed for decades: four wheels, engine, radio, doors, hood, etc. What has changed are automotive electronics. Since the 1970s, electronics have gone from about 5% of the bill of materials (BOM) to over 35% and are projected to rise to over 50% by 2030 (Statista).

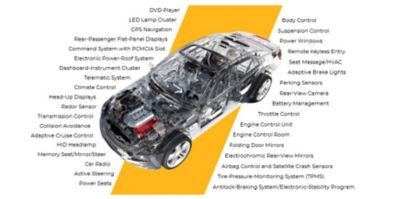

Electronics in the modern automobile

With the smartphone market saturated, the inclusion of more automotive electronics is great news for the electronics industry. But the test requirements and use environments of vehicles present reliability engineering challenges that traditional design and testing don’t take into consideration – and failures result.

Let’s look at how and why automotive electronics require consideration beyond conventional approaches to ensure successful reliability engineering.

Safety features in the modern automobile

The Four Categories of Automotive Electronics

The five-decade growth in automotive electronics can be captured in four categories.

- Functional electronics (critical to vehicle operation): anti-lock braking systems (ABS), automatic transmission control, starters, fuel injection, headlights, electromechanical parking brakes.

- Regulatory compliance electronics (mandated by the National Highway Traffic Safety Administration or Department of Transportation in the U.S.): airbags, emission controls, backup camera, collision detection radar.

- Differentiating electronics (distinct, customer-oriented technologies): infotainment, adaptive cruise control, Wi-Fi connectivity and advanced driver assistance systems (ADAS).

- Growth opportunities (for vehicles in general): collision detection, in-dash displays, head-up displays (HUD), enhanced infotainment systems, vehicle-to-vehicle communication (V2V) and improved Wi-Fi.

Not so neatly categorized is the advent of autonomous vehicles. Autonomous vehicles offer great potential for improvements via an increase in highway capacity and traffic flow, faster response times than human drivers, less fuel consumption and less pollution. Automakers are working hard to ensure these vehicles operate safely in both everyday traffic and harsh off-road environments in an effort to overcome some skeptical consumer perceptions.

Reliability Engineering Challenge: Testing for Failure

The computer environment in which electronics operate is relatively benign, typically including:

- Immobility/limited vibration.

- Little to no mechanical shock.

- Low humidity/controlled temperatures of office environments.

- Predictable duty cycles.

Under these conditions, concerns for reliability are typically an afterthought. However, the stressors that automotive electronics are exposed to change the game completely. These stressors include:

- A broad range of use cases.

- Elevated temperatures.

- Large temperature swings.

- Sustained periods of vibration and, in the case of accidents, sudden shock.

One of the challenges of automotive electronics is the difficulty in using environmental testing for design verification (DV). Failure mechanisms in electronics are difficult to accelerate. Electronics can be embedded in large systems that require long dwell times to stabilize temperatures, and failure behavior can be problematic to detect. Attempts to overcome these limitations by leveraging experiences in other markets (like computers) is increasingly limited as automotive OEMs find themselves on the forefront of the latest technology.

Reliability Engineering Challenge: Semiconductors and Board-Level Reliability

Numerous publications have acknowledged that the shrinking feature size of today’s digital integrated circuits (down to 4nm!) makes it increasingly likely that they will be first to fail in the lifetime of an automobile, long before traditional areas of concern such as corrosion (body panels), fatigue (welds), and wear (belts). This is especially true with autonomous taxis that will combine state-of-the-art electronics devices with round-the-clock operation. Placement and operation of the devices become critical, as different environments accelerate different solid-state mechanisms:

- High temperatures accelerate dielectric breakdown and bias temperature instability.

- Cold temperatures accelerate hot carrier effects.

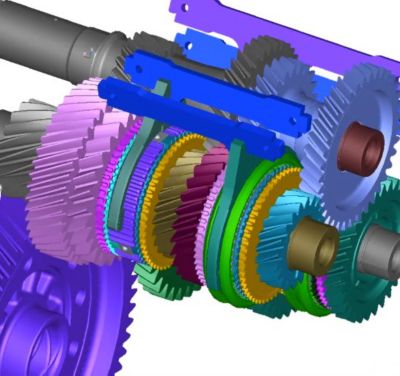

Simulation of a drivetrain in Ansys Motion

This increasing risk has been acknowledged by best-in-class design teams within automotive Tier 1 suppliers and OEMs, who are increasingly looking for alternatives to traditional design rules, design reviews and physical testing. The most promising approach, already implemented by several organizations around the world, is to introduce more simulation into the DV.

Design for Reliability Best Practices

The challenges presented by automotive electronics are real, but they aren’t insurmountable when design for reliability (DfR) best practices are applied early in the lifecycle — before the board is even built. Ansys offers a complete workflow for automotive electronics reliability, using a range of software tools based on robust and fully validated simulation engines. These include foundry models embedded within Ansys Redhawk and Ansys Totem, electromigration prediction within Ansys SIwave and reliability prediction with Ansys Sherlock. Sherlock helps to rigorously qualify products against automotive stressors, including thermal, shock, vibration and higher density board challenges. The result? Reliable products, less time spent on product qualification, reduced test cycles and related costs.

As in other industries, rapid advancement in automotive electronics is, and will continue to be, inevitable. Access the Ansys Sherlock Free Trial and start improving your electronics reliability.

Or attend the first of our three-part webinar series on Automotive Electronics Reliability:

Part 1: Meeting Automotive OEM Specs with Virtual Validation