-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

NOVEMBER 15, 2018

The Need for Speedy Innovation in the MRO and Aviation Industries

I’ve listened to many presentations at the maintenance, repair and overhaul (MRO) conference on the future of aviation. It’s fascinating to see how executives and decision-makers attending the conference react to possible evolutions of complex flying machines.

However, I have big concerns for the aviation industry.

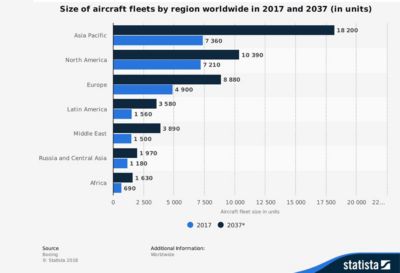

Statista and Boeing’s estimates of aircraft fleet size in 2017 and 2037.

It’s estimated that there were around 24,000 commercial aircraft flying in 2017. This fleet size is expected to grow to 35,000 by 2027 (according to Oliver Wyman) and 48,500 by 2037 (according to Statista and Boeing). Since older planes will need to be replaced and there is a demand for larger fleets, OEMs will need to step up production.

These fleets won’t be replaced at once. This means that there will be a mix of old and new planes flying around. This mix of aircraft creates more work for the MRO market as they aim to service them all. As a result, the MRO market is expected to expand even faster than the fleet expands. Estimates from Oliver Wyman show it exceeding $109 billion in 2027 versus a current value of $75.6 billion in 2017.

This data suggests the aviation industry is strong and safe. However, this could also be a trap for major players — or an opportunity for disruptive newcomers.

History Teaches Industry Leaders a Hard Lesson on Disruption

History has taught us that no company is safe. Even companies at the top of their industry can be deposed or crumble into obscurity.

This is because dominance makes companies more averse to risks and the adoption of innovations. Faster and more disruptive newcomers can step in and win your market.

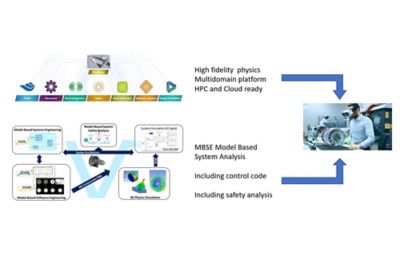

Startups are using simulation for more than just design validation. It can be used to optimize the whole product lifecycle.

We have just seen this in the space sector. A bunch of startups used simulation to develop new, revolutionary and cheaper solutions. In doing so, they were able to win market share against well-established corporations who dominated that market since its inception.

Technology isn’t the main reason behind the success of these disruptive organizations. It’s the pace of adopting innovation that truly sets them apart.

Take additive manufacturing, for instance. I saw the first tests eight years ago. However, I have not seen 3D-printed components fully qualified by the main space agencies. The big players are not taking the risks — but startups are.

Startups have the adoption advantage. They are not constrained by old workflows and processes. They are not worried about trying to certify something new. Their motto is to fail faster and fail cheaper. This idea centers around using virtual testing as the main way to get knowledge. In other words, simulation is the way startups learn how a new system will perform.

Startups are not using physical tests to fine-tune their designs — as many established companies still do. Startups only use physical tests to confirm what they already know and what has been optimized through simulations.

What the MRO and Aviation Industries Should Look for in Innovation

At the MRO conference, many players felt the need for innovation, but not the urgency.

Big players are pushed by the increasing costs of materials and labor. As a result, they focus on reducing inventory and unscheduled aircraft groundings.

To address these areas of focus, the aviation industry is interested in automation, digitalization, aircraft health monitoring and predictive maintenance.

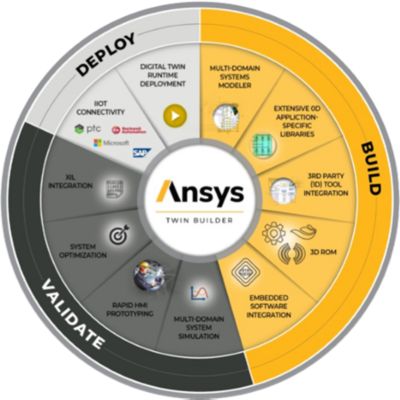

Twin Builder can bring the benefits of simulation to the MRO market.

However, the adoption of these tools is slow because it is based on technology readiness levels (TRL). TRL is a process of well-defined steps that ensure safety. Unfortunately, these baby steps are small and involve numerous physical prototypes that are slow and expensive.

There is value in TRL, but the aviation industry needs to add other factors into the equation or this process will lose the race against disruptive organizations. These factors need to ensure safety on the same level — or better — than TRL but in less time.

Companies need to think like startups by embracing simulation. To see these strategies in action, MRO companies need to look at the disruptive companies in the space industry. Instead, they ignore them.

Don’t believe me? At the MRO conference, one of the largest aerospace and defense (A&D) startup incubators, had a very fascinating presentation about their interests in joining the commercial aviation industry. Most of the MRO attendees left the room.

That tells me a lot about the industry’s mindset. They don’t see the baby tiger growing in their midst. And they don’t see the limitations of their current processes.

Ansys, however, recognized the value of disruptive companies and their methods when it created a program to help startups develop their products faster. Many of the startups enrolled in our program are aiming for the A&D industry.

Simulation Is Pervasive and Is Going Beyond Product Design

The goal of simulation has always been to reduce the time and costs associated with technology development, insertion, maintenance and updating.

So far, most companies only benefit from using simulation in the product development phase. These organizations lose the huge opportunities that can come from simulation in the pre-design phase — where decisions that involve up to 80 percent of the development costs are incurred.

How about using engineering simulation in the MRO industry? In this case, simulation can benefit the maintenance stage of a product’s lifecycle through a digital twin’s predictive maintenance features.

However, many predictive maintenance systems are based on PLM and data analysis. These systems need statistics and a long history of failures to be able to predict anything.

But, how can you train a digital twin’s predictive maintenance system to accept new components? New components have no history. They are designed differently and will fail in different ways. There is no way to predict failure through data analysis alone.

Simulation can fill this failure database gap. You don’t have to wait 20 years to gain a database large enough to predict a product’s behavior. Instead, you can simulate conditions that cause the product to fail and fill this database much faster.

In fact, the few companies that are shining in the realm of the digital twin are the ones who are including engineering simulation data in their predictive maintenance systems. For example, look at PTC ThingWorx’s integrations with Ansys’ simulation technology or products like Ansys Twin Builder. Twin Builder speeds up the creation of digital twins that are powered by simulated physics — not just by old stats.

Simulation can also help the aviation industry though other parts of a product’s lifecycle. It can reach far beyond pre-design, design, MRO and the digital twin. For instance, simulation can help the aviation industry adopt new technologies, including:

- Emerging production technologies like additive manufacturing.

- Control technologies similar to autonomous vehicles in the automotive sector.

- Machine-to-machine communication technologies like the Internet of Things in the consumer electronics sector.

The complexity of these activities requires a proven, integrated, multiphysics and multidomain simulation platform. This is the only way to identify and assess problems and failures.

The Ansys platform has been designed to be open and customizable. For example, it is CAD and PLM agnostic — meaning it can fit into various legacy workflows. The tools and the knowledge are available and proven. We just need the right mindset in place.

The companies that will get it will be the market leaders of the future. Some that don’t get it may be forgotten. Based on my experience at the MRO conference, however, I’m expecting to see new brands winning the market with revolutionary ideas someone else wasn’t fast enough to introduce.

If you are a startup looking to take down Goliath, take a look at the Ansys Startup Program.