-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Mixing applications are integral to many industries, from food and beverages to pharmaceuticals and chemicals. Designing and scaling up mixing tanks for these types of applications present a myriad of challenges for process engineers, including determining the appropriate design configurations, operating variables, and material properties.

Computational fluid dynamics (CFD) modeling techniques can help estimate these critical performance parameters in mixing tank designs, but often at the cost of either fidelity or computational speed. Using the fusion model, you can streamline the workflow for combining data-driven and physics-based modeling to enhance simulation fidelity and turnaround times for simulating mixing processes. In addition, the workflow can be deployed in a customized app to empower nonspecialists to use simulations efficiently during their mixing process design.

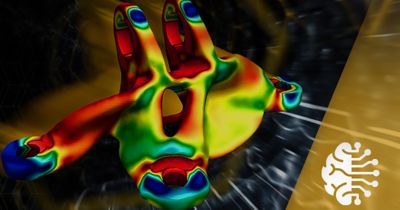

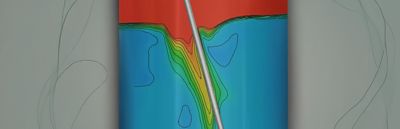

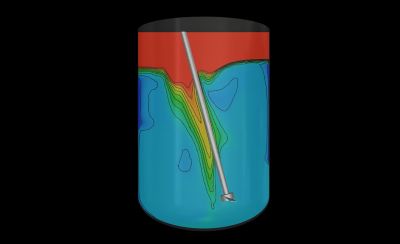

Figure 1. Simulation of a mixing tank using Ansys Fluent fluid simulation software

What Are the Limitations of Current Blend-time Estimation Methodologies?

Depending on the stage in the design cycle and simulation fidelity requirements, there are different computational approaches that may be used to model mixing tank performance. The multiple reference frame (MRF) approach is a steady-state approach that can model the effect of rotating blades in a mixing tank in a relatively quick manner. However, depending on the operating conditions, material properties, and the complexity of the tank configuration, the approach may not always be highly accurate.

Modeling the blade rotation explicitly using the transient sliding mesh approach, on the other hand, provides higher accuracy, but at a high computational cost. Both methodologies are not ideal, and there is a need to determine a new method that provides both computational efficiency and high accuracy.

Fusion Model: A Machine Learning Approach To Enhance Simulation Fidelity

The fusion model is a machine learning technique that combines high-fidelity data from simulations or experiments with lower-fidelity data from simplified approaches. This results in improved overall fidelity by training a machine-learning model to predict the error trends between the two datasets at a lower computational cost. This approach is offered in Ansys TwinAI AI-powered digital twin software and is employed in the steps below to enhance blend-time estimation in mixing tanks.

The first step in the workflow is to generate two datasets, one for the low-fidelity MRF method and the second for the high-fidelity sliding mesh method, which will be used to generate the fusion model. The variables considered in these datasets are agitation speed, solute viscosity, and solute density, and the monitored quantity is the blend time (i.e., the time to reach a fully blended condition).

Start by setting up a parameterized steady-state CFD simulation in Ansys Fluent fluid simulation software using the MRF approach. Next, perform a design of experiment (DoE) to construct the design space and generate a fast but lower-fidelity MRF dataset of blend time as a function of the design input parameters. Then, select a few design points that are optimally distributed over the design space to generate another dataset of higher-fidelity (but computationally more expensive) predictions using the transient sliding mesh approach.

Finally, the two datasets of blend time as a function of the design variables are input into TwinAI software to generate the fusion model. The generated model receives the low-fidelity MRF blend time along with the design input variables and outputs a blend-time estimation with enhanced fidelity.

Using Reduced-order Models for Quick Prediction

Reduced-order models (ROMs) are a simplification of a high-fidelity engineering simulation while preserving essential behavior and dominant effects using a data-driven algorithm. ROMs are a key technology enabler that can help speed up development cycles.

To enable a quick blend-time prediction, a ROM for the mixing tank is generated out of the computationally efficient MRF inside the Ansys Twin Builder simulation-based digital twin platform.

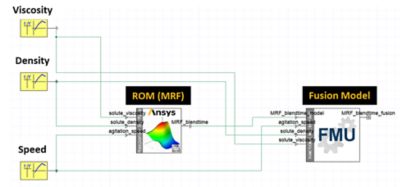

The output of the ROM is passed to the fusion model to enhance its fidelity, as shown in Figure 2. The results of this integration are a quick and accurate streamlined workflow for blend-time prediction as a function of user’s design variables of agitation speed, solute viscosity, and solute density.

Figure 2. System model integrating the reduced-order model (ROM) of the mixing tank with the fusion model

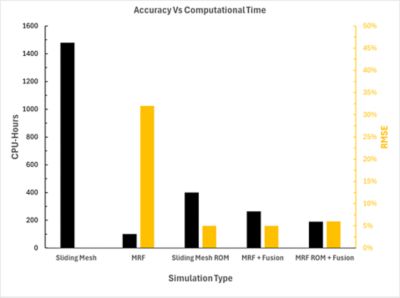

This hybrid approach enabled an eightfold reduction in design process time in comparison to conducting the entire design process using the transient sliding mesh approach and without sacrificing accuracy. The root mean square error (RMSE) in the MRF model is reduced from 32% to 6% using the fusion model, as shown in Figure 3. The combination of machine learning and physics simulation speeds up the design process, enabling faster time to market.

Figure 3. Comparison in computational time and accuracy over distinct simulation approaches

Consumption of the Fusion Model via a Customized App: Enabling Nonspecialists To Run Simulations

Running simulations is no longer exclusive to simulation experts. Nonspecialists can also benefit from physics simulations through automated workflows deployed in customized apps. Using the PyAnsys pythonic access tool for Ansys software, engineers can connect Ansys tools to custom apps and build easy-to-use interactive apps that receive specific user inputs and output the simulation results. An example is illustrated in the video in Figure 4. The app encapsulates the developed workflow such that it receives the design variables, including agitation speed, liquid viscosity, and density, and interactively predicts and plots the corresponding blend time.

Figure 4. Example of a custom app to enable nonspecialists to run simulations in a streamlined, straightforward way

Get Started Today

The fusion model and ROMs have potential to revolutionize how mixing processes are designed. Available capabilities in Fluent software, TwinAI software, and the Twin Builder platform empower process engineers to seamlessly enhance their designs and build automated workflows.

Access our Ansys Learning Hub (ALH) course “Ansys Twin Builder Getting Started: Co-Simulation and ROM” to learn more. (ALH access is required.)

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.