-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

October 22, 2018

How to Ensure Your Large Deformation Simulation Mesh Will Converge

It’s tricky to get your mesh to converge as it undergoes large deformations.

This is typically a challenge for analysts that investigate the simulation of elastomeric sealing, bending and metal forming.

The convergence issue is triggered by mesh distortions. If every time step sees your elements change in size and shape while experiencing increasing loads, then you know what I mean.

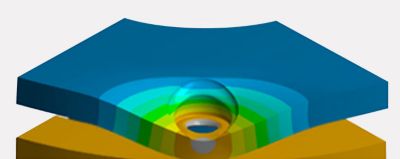

Simulation of a bolted retainer converges because NLAD will remesh the geometry as it deforms.

These mesh deformations wreak havoc on your simulation’s accuracy and convergence because of nonlinearities in the mechanical and thermal behavior. But, how do you get your simulation to converge if the mesh keeps moving?

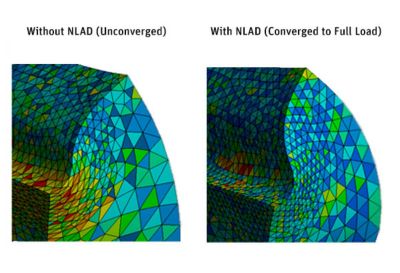

Element quality comparison between a simulation without

NLAD and one with NLAD. Only the simulation with NLAD converges.

The answer is the nonlinear adaptivity (NLAD) feature in Ansys Mechanical.

The tool automatically repairs the mesh distortions that trigger convergence issues under large deformations. From there, the tool refines the mesh as it distorts to ensure local phenomena are captured correctly.

How to Remesh Geometry Under Large Deformation

The NLAD tool will automatically remesh the geometry. However, you control how often this happens.

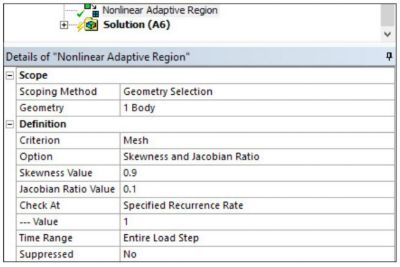

This control is set up through various criteria in the details panel.

If one criterion is met during the simulation, it triggers a specific mesh modification algorithm that is linked to that criterion.

A typical NLAD set up in the details panel

The criteria that control NLAD are based on:

- Location.

- Contact status.

- Strain energy.

This means that the remesh can be limited to a local area that is being distorted. This will reduce the computational cost of the simulation.

To see examples where NLAD helps analysts converge bending, bolting and elastomer simulations, read Adapting Large Deflection Simulations Confidently with Nonlinear Adaptivity (NLAD).