-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Ansys博客

February 15, 2024

Infinitum:电机设计助力实现更高效、更可持续的未来

全球有数十亿台电机在维持这个世界的运转——如今,它们总共消耗了全球一半以上的电力,其中大部分消耗来自大排放量的燃煤发电厂。这就是为什么电机效率的任何改进都具有重要意义——其可以显著推动全球脱碳工作,并加速向电动汽车的过渡。

鉴于此,总部位于德克萨斯州的Infinitum制造商研发出了一款比传统铁芯电机更轻、能耗更低、排放更少的新一代电机。

通过Ansys初创公司计划,他们在Ansys Fluent和Ansys Maxwell软件的助力下获得了成功。该公司表示,其在整个产品组合中使用了空气磁芯技术。利用该技术,能够生产出比具有相同功率输出的传统电机体积和重量减少50%、制造碳密集度降低近20%、效率提高10%的电机。

减轻重量并减少排放

印刷电路板(PCB)定子技术是空气磁芯与众不同的关键所在。

定子是电机中的固定组件,其在施加交流电流时会产生旋转磁场。大多数定子由层压铁芯和通常采用铜材料的绝缘导线线圈(被称为绕组)组成。

自电机在一个多世纪前发明以来,其一直在使用铁芯,但这并不意味着该方案是完美的。首先,铁芯很重,并且铁矿石的开采过程并不环保。

此外,铁芯定子很容易出现性能问题,最明显的是铁芯损耗(与感应涡流和磁滞相关的能量损耗)、扭矩波动(扭矩输出的周期性变化)以及齿槽效应(一种不必要的扭矩现象,会导致运动中产生抖动)。

通过从定子中去除铁芯和铜绕组,并在两个磁性转子之间使用获得专利的PCB定子进行替换,Infinitum提高了其电机的性能尺寸比,减轻了重量,减少了扭矩波动和齿槽效应的影响,并减少了涡流损耗。在该设计中,磁通量穿过没有包含铁芯的两个转子,因此该方案被称为空气磁芯。去除铁并减少电机中的铜使用量(定子中仍有铜绕组,其对于实现功能至关重要),这意味着同时减少了资源使用和铁矿开采带来的负面影响。总的来说,这也意味着在制造电机时,碳排放减少了近20%。

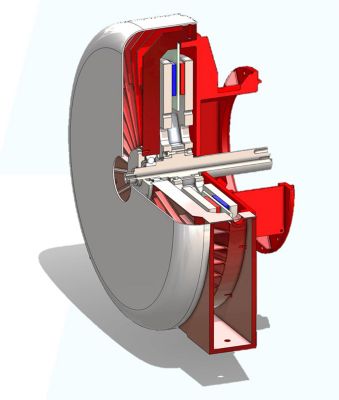

高效率、低重量交流发电机的渲染

量化损耗

涡流会产生热量,这样的能量损耗会导致效率降低,因此,最大限度地减少电机、发电机和变压器中的涡流至关重要。当Infinitum开始开发PCB定子时,其通过内部设计工具计算出涡流损耗将达到126W(瓦特)。然而,测试时显示损耗为330W,比预估的数字要高得多。为了调查该差异,工程师转而使用了Maxwell。

考虑到涡流是在离磁体过渡最近的位置产生的,Infinitum工程师使用Maxwell来检查简化的定子模型,重点关注单个铜线圈的直绞线与快速通过的磁体之间的相互作用,而不会影响全尺寸定子的保真度。

Maxwell仿真结果表明,涡流主要局限于最靠近磁体过渡的三根中央线圈绞线,并进一步受到线圈和磁体之间气隙大小的影响。通过对完整定子中所有线圈的仿真结果进行推导,Infinitum工程师确定,是线圈中相邻绞线之间的邻近效应导致了设计预估结果与现实情况之间的差异。

为了处理PCB定子建模和测试之间的差异,Infinitum工程团队调整了其内部设计工具所使用的闭式解,以便未来的测试将能够与仿真中获得的结果高度吻合。

顺其自然

对于任何电机制造商而言,热传递、热损耗和冷却都是重要的考虑因素,但当您的产品体积小巧但功能强大时,其利害关系就会更大。Infinitum使用Fluent进行热管理仿真,包括在为客户设计定制的空气磁芯产品时。

最近,一家建筑和采矿设备行业的领先企业要求Infinitum开发一款高效、轻量化的空气磁芯交流发电机原型,该交流发电机可与现有发电机集成,提供20kVA(千伏安)的功率,并以1500RPM(转每分)的速率运行。

在使用内部系统对满足项目电气和接口要求的初始机械设计进行建模后,Infinitum工程师转而使用Fluent来改进第一次迭代的空气冷却系统。

以均匀的定子温度和高效率主要目标,Infinitum开始着手定制设计,并通过内部空气循环和旨在排出系统空气的机械驱动叶轮的流速实现必要的冷却。此外,工程师还评估了新开发的定子外壳壁的传导冷却功能,这种外壳壁具有扇形接触区,与均匀但较薄的接触区相比,这种设计通过传导提供了更稳定的冷却。

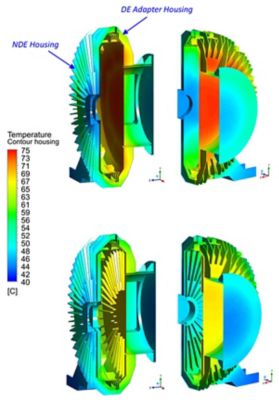

外壳温度图(左)和定子温度图(右)

Fluent仿真显示,虽然在定制过程开始时,定子的整体温度处于可接受的低水平,但最初的叶轮概念(基于之前的Infinitum径向叶片设计)却由于风阻损耗而效率下降。在12个叶片、外径为390mm(毫米)和深度为42mm的条件下,第一次迭代的叶轮产生的流速为700CFM(立方英尺每分钟)。工程师去除了四个叶片,将外径减小到290mm,深度减小到30mm后,仿真显示流速下降到了更高效的300CFM。这个临时叶轮,在冷却系统之后的两次迭代中都发挥了作用。

事实证明,外壳翅片的布局和数量也对该系统的成功至关重要。尽管在工程师修改叶轮后,定子温度仍保持在预期限值内,但交流发电机外壳的驱动端和非驱动端之间仍存在显著的温差。工程师得出的结论是,驱动端外壳上缺少内部翅片,阻碍了对称冷却。在将内部翅片添加到外壳设计后运行的仿真显示,定子和外壳的温度梯度都更低、更均匀。

流动结果证明,外壳壁的扇形特征通过传导成功耗散了28%的定子热量,同时,设计人员在外壳周围添加了翅片,以帮助进一步耗散。这次迭代还表明,外部机匣的轮廓无法有效地将空气输送到外壳翅片,并且现有的较低安装位置导致其中一部分外壳的二次气流阻塞。进一步的仿真证明了,修改机匣轮廓以遵循翅片轮廓并减小安装特征的尺寸可解决这些问题。

为了最终确定内部动力流的叶轮设计并确定建议的外部流速,Infinitum使用Ansys CFX和冷却系统的简化机械模型进行了质量流要求研究。

不带内部翅片的外壳温度(上)和带内部翅片的外壳内部温度(下)

在这个质量流仿真模型中,去除了电气连接凸台和安装支脚,并根据计算流体力学(CFD)结果修改了机匣,这样可将空气引导到交流发电机外壳上,以取代现有的机匣连接。根据铸造供应商的规范,外壳材料被更改为了灰铸铁,翅片厚度设置为6mm,基础壁面厚度设置为10mm。当内部转子转速设置为1500RPM时,外部流量在100到400CFM之间变化,而热载荷在100%到130%之间变化。

通过绘制和推导定子温度与外部气流曲线以及系统阻抗曲线,Infinitum确定了其设计的最小工作点和建议的工作范围。基于这些研究结果,该公司研发了一种具有300CFM流速的叶轮,并使用3D打印制作了原型。

前沿仿真软件的建模和测试功能使设计人员和工程师能够对无限的变量进行试验,而不必受制于使用物理模型所需的大量时间和资金成本。得益于这些优势,Infinitum成功地进入了专业市场,虽然仍处于起步阶段,但这应该是对数字工程价值的有力证明。Infinitum的示例证明了,在一个几代人都没有实现重大技术进步的行业中,仍然有可能进行颠覆创新,并为解决一些世界上最棘手的问题开辟了新方向。

进一步了解Ansys初创公司计划,查看申请资格、软件包和成功案例。