-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

September 24, 2021

How Hargrove Engineers + Constructors Extended the Life of a Major Chemical Company Condenser Using Ansys Mechanical

When routine inspections of a major chemical company plant revealed an unacceptable thinning in the walls of a condenser tank, the company called on Hargrove Engineers + Constructors to evaluate the condenser and suggest mitigation efforts that might avoid the costly, labor-intensive replacement of the tank. Hargrove is a full-service engineering, procurement, construction management, project management, controls and automation, and technical services firm.

Ansys Mechanical simulations performed in Ansys Cloud were instrumental in analyzing the problem and developing a unique solution. Benjamin Turner, a mechanical engineer at Hargrove, and its customer, discussed the process in a seminar given at the Ansys Simulation World 2021 virtual conference.

“Hargrove came up with a novel solution that typically wouldn’t be possible without using finite element analysis (FEA) options like Ansys Mechanical,” said Hargrove’s customer during the Simulation World presentation.

Detecting the Problem

Corrosion is one of the main culprits in system deterioration in a chemical plant. In this case, a condenser (a heat exchanger comprising four different materials and thousands of tubes) corroded opposite its inlet nozzle. Field ultrasound tests performed during a routine inspection revealed a wall thickness below the API-579/ASME Code minimum allowable thickness for external pressure in such a vessel.

“Some of our chemicals push the very limits of available mechanical and material technology,” Hargrove’s customer said. “That’s why we continually monitor our equipment and mitigate the risk as quickly as possible.”

Assessing the Damage

API/ASME codes provide three levels of Fitness-for-Service Analysis of a defect in cases like this. Levels 1 and 2 use analytical calculations to quickly determine whether identified defects are acceptable. Each level increases the complexity of the calculations. In this case, the major chemical company’s Level 1 and 2 analyses didn’t give a clear answer as to whether the condenser could be repaired, re-rated for use at a lower pressure or modified process conditions, or required replacement. That’s when they called in Hargrove.

“Level 3 requires the entire equipment to be modeled exactly in FEM (finite element modeling), including the defects,” said Turner. “We need Ansys Mechanical for such a complex process.”

Turner explained that Level 3 Fitness for Service Analysis recognizes five failure modes: plastic collapse, local ductility, ratcheting (a progressive deformation from cycling), fatigue and buckling, which is a geometric deformation from compressive forces.

“The condenser operates under full vacuum conditions on the shell side as the process flow turns from gas into liquid,” Hargrove’s customer said. “Our largest concern was gross buckling on the shell side.”

Buckling occurs when local sections become too thin and the vessel can no longer resist the force of the atmosphere pushing against the shell, Turner added. The vessel can actually collapse inward like a soda can being crushed.

Running the Simulations

In modeling a complicated condenser with thousands of tubes, expansion factors and nozzles, it would be too computationally expensive to develop a model out of solid elements. Instead, Hargrove engineers modeled the condenser system as shell-and-beam elements, with the tubes acting as beams welded to the tube sheet and the outside pressure membrane represented as shell elements.

Even with these simplifications, the model was rather large computationally, so they used Ansys Cloud to get the extra computing cores they needed to run the simulations faster. They chose the large displacement theory available in Mechanical to model the nonlinear buckling as it occurred. The three loads of concern — gravity, thermal and external pressure —were added sequentially during the simulation.

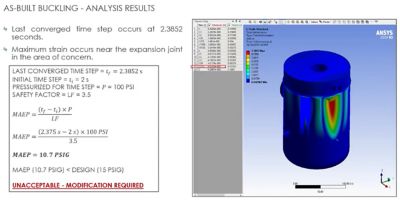

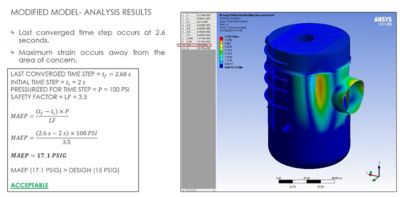

“We chose a very large external pressure and then we let the simulation run until it failed to converge, Turner said. “This is known as the limited load analysis. The last converged iteration gives us the largest external pressure that the vessel can withstand before the vessel collapses. When the solution diverges it represents vessel failure, so our last converged analysis is the last stable shape.”

Based on these simulations, Hargrove Engineers + Constructors was able to suggest a fix to their customer, that was much less costly than a labor-intensive replacement of the condenser system. To learn more about this novel solution, read the Ansys + Hargrove case study here.