-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Ansys博客

November 15, 2023

科德宝为海运行业带来电力解决方案

船载氢燃料电池系统能否成为海运行业一直在寻找的脱碳工具?

德国科德宝电子动力系统(Freudenberg e-Power Systems)的工程师认为,他们已有这样的解决方案。

生产各种工业技术和产品的科德宝集团,于2022年成立了科德宝电子动力系统(FEPS)业务集团,致力于为船舶(交通运输行业最大的温室气体排放源之一)提供可扩展的碳中和动力与推进系统。

他们为重型工业减少对化石燃料依赖的创新理念是,提供一种紧凑型船上化工装置:利用氢生成模块,将甲烷或甲醇转化为氢气,供应给低温聚合物-电解质薄膜燃料电池(PEMFC)组。单个这样的系统可产生500千瓦的净发电量,多个系统可以组合在一起,以满足船舶的能源需求。

图1:科德堡海上PEM燃料电池系统一览。该系统包括氢生成模块、燃料电池模块和电子模块。氢生成模块是一种化工装置,可将甲醇或甲烷转化为富氢重整气。富氢重整气会被提供给燃料电池模块。燃料电池模块包括多个重型燃料电池组,这些电池组通过燃料电池内部氢气和氧气的电化学反应产生电力。然后,电力通过电子模块供应给船舶。© Freudenberg e-Power Systems

工程师使用Ansys Fluent、Ansys nCode Design Life和Ansys Mechanical对该装置的燃料电池、反应器和其他组件进行建模。他们还使用Ansys Cloud Direct进行高性能计算(HPC),这在执行多尺度仿真时尤为有用。

科德宝系统仿真工程师Stephanie Frankl博士表示,仿真帮助该团队处理了众多关键任务,比如最大限度地提高氢能生成、延长燃料电池使用寿命和优化组件耐久性等。

仿真不仅有助于处理这些工作,而且还提供了重要的时间和成本节省优势:减少了原型设计之前所需的设计迭代次数。

业务越多,问题越多

全球超过80%的商品贸易都是通过海运进行的,人们将原材料从一个港口运送到另一个港口,再将成品运回,。这意味着全球航运是一项大型业务,而且疫情过后也在不断发展:预计今年全球集装箱船队将增长6.3%,2024年将增长8.1%。1

虽然,这在经济层面可能是一个积极的消息,但其会带来巨大的环境代价。全球航运业每年产生的温室气体排放量约占全球总排放量的2.8%2,这还不包括游轮,而游轮的碳密集度比任何其他类型的船舶都要高。尽管国际海事组织(IMO)制定了一个宏伟的目标,即到2050年左右实现国际航运温室气体(GHG)净零排放,并承诺到2030年确保采用零和近零温室气体替代燃料,但令人担忧的是,随着货运量(和乘客量)的增加,排放量也会增加。3

但正如海运和游轮行业所指出的那样,要缩小目标与现实之间的差距,就需要技术创新,而且目前没有人浪费时间,大家都在积极应对这个问题。从行业顾问到欧洲海事安全局,每个人都在全力以赴地研究传统内燃机的推进和船载动力的替代方案。自2016年以来,大家一直把研究重点放在燃料电池上,虽然已经考虑了多种类型的方案,但人们的共识是,仅需氢气和氧气就能发电的低温PEMFC对航运业来说最有前景。

科德宝的工程师在利用PEMFC优势的同时,也瞄准了在船舶上使用PEMFC的最大障碍之一:在不占用太多宝贵载货空间的情况下储存大量氢气。

一种新颖的方法

在交通应用中使用低温PEMFC并不新鲜——它们已经被用于为重型卡车和公共汽车供电有一段时间了,并因其紧凑的设计和高能量密度而备受青睐,这意味着它们可以在较小的质量内储存大量能量。由于其在低于100°C的温度下工作,因此可以快速启动。

然而,在船舶上使用PEMFC的关键诱因在于,它们通过氧气和氢气之间的化学反应产生电力,而不会释放任何有害排放物。当然,要做到这一点,就需要氧气和氢气,这就引出了该方法的挑战之一:在船上储存足够的氢气,以满足海上船舶的功率或航行距离要求。

从环境中捕获氧气非常容易,但氢气却不能凭空而来。相反,氢必须与分子中的其他元素分离,然后以液态或高度压缩气体的形式储存。无论哪种方式,由于氢的体积能量密度相对较低,即在给定的能量储存量下,它会占用相对较大的体积,因此在船上储存足够的氢气可能需要多个大型燃料罐,这就会挤压载货空间。

科德宝解决方案采用紧凑型蒸汽重整装置,将易于运输、处理和储存的绿色甲烷或甲醇转化为氢气。全球近一半的氢气生产都来自蒸汽重整,它被认为是目前最先进的方法。4燃料电池内部的总反应与内燃机中的直接燃烧反应完全相同,只是不会产生氮氧化物排放。相反,燃料中储存的化学能直接转化为电能,只排放水蒸汽。

当然,有机化学的基础知识告诉我们,甲烷和甲醇中含有大量碳,这就引出一个问题:是如何实现净零过程的呢?正如FEPS的工程师所指出的,当甲烷和甲醇由绿色氢生产时,生产过程中释放的任何CO2都会在此之前被捕获,因此形成了一个CO2的闭环。换句话说,成分产物的来源至关重要,这也是科德宝所考虑的因素。

数十年的使用寿命

开发其船载装置时,科德宝工程师无需彻底改造PEMFC技术。但他们确实需要开发出一种用于航海船舶、使用寿命长达数十年的燃料电池——比汽车应用中的燃料电池使用寿命要长得多。

这正是Fluent及其强大的网格划分功能发挥作用的地方。

燃料电池的使用寿命取决于许多变量,但组件设计和工作条件因素,是开发一款能够持久使用的产品的关键。延长每个燃料电池组件的使用寿命意味着要考虑无数的独立需求。例如,燃料电池中的反应气体必须分布均匀;对于聚合物膜,则需要均匀的温度。

Fluent仿真使工程师能够研究工作条件对燃料电池内部组分、温度和电流分布的影响,并对其可视化。

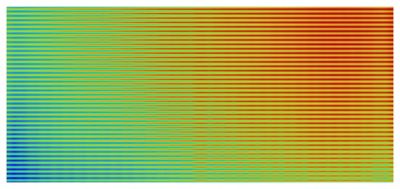

图2:使用Ansys Fluent对燃料电池薄膜内部的温度分布进行仿真和后处理。蓝色表示低温,红色表示高温。© Freudenberg e-Power Systems

这项工作涉及通过组合两个网格来创建计算域,总网格数超过5,000万个单元。 科德宝燃料电池工程师Victoria Damerow表示,由于燃料电池模型的几何结构非常复杂,因此网格划分对于燃料电池仿真尤为重要。

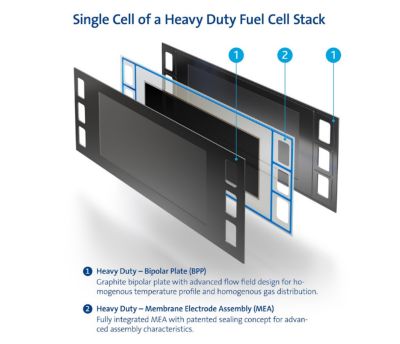

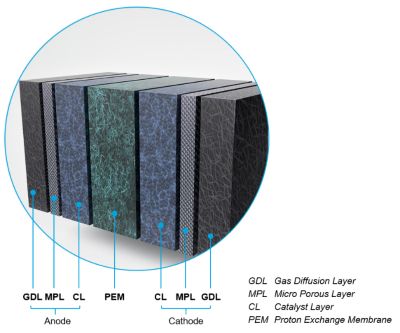

Damerow说:“这种复杂性是由燃料电池的多尺度特性造成的,因为燃料电池的几何结构既包括厘米级的组件(例如双极板),也包括微米级的组件(例如膜-电极-组件)。”

图3:科德宝PEMFC的单电池组件,包括两个双极板和膜-电极-组件(MEA)。双极板引导反应物流向MEA。© Freudenberg e-Power Systems

图4:PEMFC的膜-电极-组件(MEA)结构。MEA由多孔阳极和阴极电极以及质子交换膜(PEM)组成。该膜由电子非导电聚合物制成,从而将阳极与阴极侧隔离开来。不过,该聚合物能够将质子电荷从阳极转移到阴极侧,这是在阳极和阴极催化剂层(CL)中实现氢气和氧气的电化学半电池反应所必需的。电极还包括气体扩散层(GDL)和微孔层(MPL),它们能够将气体反应物分配到催化剂层。© Freudenberg e-Power Systems

Damerow称:“燃料电池的几何结构包括非常薄且明显较大的组件。因此,在不同尺度上创建具有足够分辨率和质量的网格,同时保持计算成本的可控性,对我们来说是一项巨大的挑战。Ansys提供了一系列网格划分工具,我们采用了其中最适合相应燃料电池组件需求的工具。通过组合不同的网格,我们获得了非常好的总体结果。可见,Ansys网格划分工具的灵活性对此用例非常有利。”

此外,Fluent还帮助工程师通过更高的甲烷或甲醇转化率来最大限度地提高制氢量,并改进热回收,从而优化系统效率。

Frankl表示:“我们必须优化反应器内部的流动,以尽可能实现最佳的燃料转化率,因为这决定了系统的效率。此外,我们还必须在流程中纳入热集成,以优化热回收。而且,我们需对用于蒸汽重整的催化剂中发生的一切进行建模。”

Frankl指出,他们在反应器开发中采用了与燃料电池建模中相同的双网格方法。

Frankl说:“我们可以使用不同的工具为每个部件构建最佳网格,这确实很方便。同时,Fluent非常擅长将所有不同的网格组合成一个,从而得到出色的仿真结果,其中所有需要高分辨率的部件都能得到充分的求解,而其他不那么重要的部件则可以使用较粗疏的网格,以节省一些计算工作量。”

船舶形状

将功能齐全的化工装置安装到货轮或其他船舶有限的空间中,并不像创建一个全尺寸设施的比例模型那样简单。

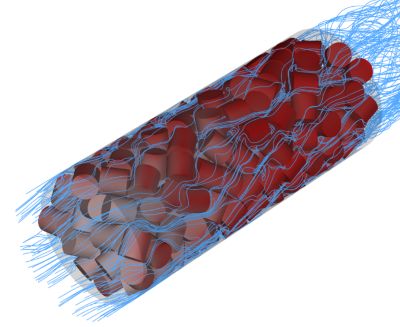

对于FEPS工程师而言,减少占用空间,不仅意味着要缩小氢供应模块的尺寸,而且还意味着要设计出他们所谓的“极具创意的反应器形状”,以满足船舶的空间需求。

图5:利用Ansys Rocky对反应器床中圆柱体的随机填充进行仿真,显示了气流的流线。在该仿真中,固定了包含填充床的管道壁面的温度,并评估了从壁面到流体再穿过填充床的传热情况。该仿真的最终目的是,验证用于填充床仿真的多孔介质方法的定制传热模型。© Freudenberg e-Power Systems

他们还必须权衡风暴或强浪可能产生振动或加速度如何影响该装置的结构强度。

利用Mechanical仿真工作条件对不同组件的影响,工程师能够在尺寸和形状与效率和有效性之间取得平衡,从而确保非常规形状的设施能够承受这些自然力,同时满足认证要求。通过将Mechanical与业界领先的耐久性分析工具nCode Design Life相结合,工程师可以全面分析疲劳状况,识别组件级别的潜在缺陷,并更好地预测该装置的运行寿命。

航行更顺畅

工程师完成燃料电池和氢供应模块的模型后,他们便将其结合起来,对整个系统的行为进行建模。下一步是验证和确认这些仿真结果,然后使用初始原型的测量数据来提高模型的准确性和可靠性。

通过这一虚拟开发流程,科德宝在可持续海运性能方面实现了真正意义上的巨大变革,响应了企业和社会的呼吁,以更低排放的方式将货物和人员从A点运送到B点。

考虑到度假游轮越来越受欢迎,以及全球贸易对货轮的依赖日益增加,PEMFC技术的这些进步应该会给国际水域和大气环境问题带来一些可喜的缓解。

对于决心参与绿色交通运动的海运行业来说,科德宝的氢动力装置很可能将助力该行业在未来几年更加顺利地发展。