-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

July 13, 2021

Fluid Dynamic Simulations Advance Appliance Designs

In the competitive world of home appliance design, particularly refrigeration, cooking, laundry, dishwashing or range hoods, pushing performance boundaries means grasping a deeper understanding of how these products operate. Tighter environmental regulations coupled with more sophisticated user experience requirements pushes the designs into territories where subtle physical behavior starts to play a more prominent role. This can mean lengthy and expensive development and testing phases.

For instance, the moisture management inside refrigeration compartments is one area where understanding condensation, heat transfer and airflow is crucial to developing a better performing product.

New Zealand-based appliance designer Fisher & Paykel uses Ansys software to carry out simulations at the early stages of product development to identify and rectify potential issues, as well as optimize designs to meet various performance criteria. They had particular success using Ansys Fluent and computational fluid dynamics (CFD) to make ice-making improvements in their refrigeration products.

Simulations are also used extensively throughout the development process; especially when various design changes pop up as the designs of related systems mature. These analyses tend to be a case of assessing multiple solutions to prioritize those that are most promising. Because of subtle differences between some of these solutions and experimental uncertainty, CFD has become the most reliable means of their assessment.

Understanding Ice Making Challenges

Fisher & Paykel’s goal was to develop a higher performance ice maker, which requires increasing air flow over the ice tray to improve the ice-making rate. This meant creating an air delivery system that is capable of channelling even flow over the ice tray.

This was no easy feat, since the company had to redirect some of the primary air that feeds into the freezer compartment into the ice maker. The challenges: dealing with the abrupt changes in flow direction and developing a design that could work with a range of different refrigerator models.

In initial discussions, the company realized multiple baffles wouldn’t work due to the chaotic, swirling airflow at the source. The solution is a zone that allows the flow to buffer sufficiently in a controlled manner before releasing into the ice maker.

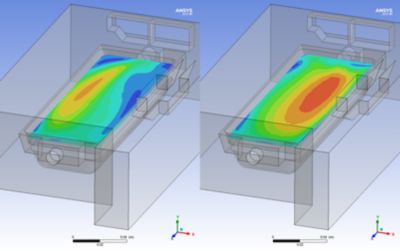

Initial ice maker design (left) and final design (right) showing improved velocity distribution over the ice maker tray.

Improving Ice Making Performance

Fisher & Paykel engineers created initial designs using end-to-end, simple swept profiles and relatively convoluted flow paths because of the need for air to make drastic directional changes in two orthogonal transverse directions over a short length.

The solution was a redesign of the duct profile using a single baffle to better control diffusion across the two orthogonal planes independently. This resulted in a 67% decrease in pressure loss compared to the initial design.

Inspired by the swirling motion of ground surface water navigating around an obstacle – and with the help of Fluent’s Adjoint solver – the company optimized the design to produce a flow with primary direction aligned with the ice tray. This resulted in an average velocity increase of over 50% and produced a more symmetric flow profile over the ice maker tray, which helps significantly improve ice-making performance.

An optimized design produced a flow aligning with the ice tray, resulting in an average velocity increase of over 50% and a more symmetric flow profile over the ice maker tray.

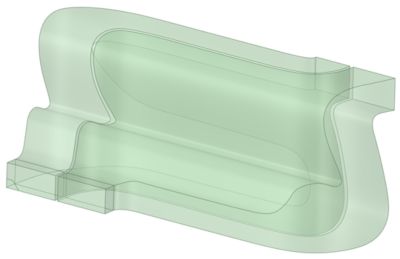

How the Flow Field Was Designed

Flow entering the duct gets drawn down into a cylindrical chamber, encouraging a swirling motion with an axis in the transverse direction to the primary flow at the duct’s entry. This allows the lateral translation of the primary flow, while minimizing losses. The flow then releases behind the ice maker through a short straight duct segment. Here, the bulge/cylindrical feature upstream of the duct outlet encourages and facilitates the transverse swirl motion, which is key when attempting to produce unidirectional flow over the ice tray.

Throughout this process, Fluent CFD simulations were used extensively. This use of simulation was much more cost and time effective compared to producing and testing 3D printed designs, which required three days per design iteration. The company could turn CFD simulations around in a single day. Additionally, when hunting for an organic shape to achieve the given performance criteria, the shape-morphing ability of the Fluent Adjoint solver was a superior approach compared to manually creating discrete design iterations.

CFD simulations also revealed an extensive description of the flow field, which enhanced the engineers’ understanding of the flow behavior. Compared to physical testing, the ability to have a greater deal of control of the test environment in a virtual model also helped Fisher & Paykel refine the product design. As well as looking at the airflow behaviors, it was paramount that any aerodynamically generated noises were also kept to a minimum in order to produce a quiet refrigerator. For this, the company used Fluent aeroacoustics simulations to assure noise level requirements were met within the CFD analysis and physical tests for assessing the final design.

Start your free trial of Ansys Fluent Pro today!