-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

June 25, 2019

New Fluent Meshing Workflow Quickly Wraps Non-Watertight, Dirty Geometries

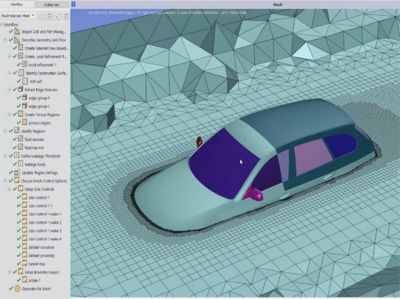

Ansys 2019 R2 rolled out a new fault-tolerant workflow that simplifies Ansys Fluent meshing of complex computational fluid dynamics (CFD) simulations.

Traditionally, engineers spend a lot of time on geometry meshing. The new workflow accelerates this process and greatly improves the user experience as a result.

In a recent release, Ansys introduced a task-based workflow that sped up Fluent meshing of watertight geometries by 70% — and with 50% fewer clicks.

The fault-tolerant workflow can easily wrap leaky geometry.

However, some of the most important and complex CFD simulations contain dirty, non-watertight geometries. For instance, the geometry used in simulations of automotive front-end airflows, external aerodynamics and complex external/internal flows can’t be meshed using the task-based workflow. As a result, these geometries require extensive cleanup before simulation.

To overcome this obstacle, Ansys 2019 R2 offers a new Fluent meshing workflow that wraps dirty geometry without cleanup.

Fault-Tolerant Workflow for Fluent Meshing Wraps and Seals Leaks and Gaps

The fault-tolerant workflow improves Fluent meshing with wrapping. The workflow enables users with minimal experience to generate meshes of complex geometries.

For example, the workflow for external aerodynamics meshing has predefined settings based on best practices.

These settings help users create:

- Moving reference frame (MRF) regions

- Heat exchanger regions

- Porous regions

- Wake regions

- Enclosed capped regions

- Tunnel regions

Ansys Fluent fault-tolerant workflow includes wrapper technology that covers and seals leakages and gaps.

Benefits of the New Fluent Meshing Workflow

The workflow for non-watertight geometry offers distinct advantages over other meshing technologies.

These include:

- Part management: Users can perform CAD-level changes to any geometry or assembly, including dragging and dropping objects from the CAD model into the simulation model.

- Leakages and overlaps: The fault-tolerant workflow seals leakages caused by gaps and misalignments between solid bodies. This significantly reduces the manual efforts required to clean up geometry.

- STL file input: The workflow can create fluid regions directly from STL files or scanned data. This eliminates the need to convert STL files into solid geometry for the biomedical, oil and gas, automotive and other industries.

- Large assemblies: Users can create fluid regions from full assemblies for various simulations — like a level front-end cooling analysis. The fault-tolerant workflow can handle subassemblies and solid bodies, which are usually unnecessary for geometry definition.

- Sharing, saving and editing: Users can save their work and return to any point in the meshing process. The file can also be saved and shared with team members, to get a head start on meshing the next design iteration.

The new Fluent meshing workflow is a significant timesaver. Overall, benchmarks indicate that an engineer experienced with Fluent will see a 2X speedup. The workflow virtually eliminates scripts, manual interventions or pop-ups —making it more accessible and easier to learn.

To learn more, visit the Fluent product page or watch the demo below.

Watch the fault tolerant workflow in action in this video. Cyclist geometry provided courtesy of Centre for Sports Engineering Research, Sheffield Hallam University.