-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

April 17, 2019

Discover How Ferrari Competizioni GT Produces Simulations 3x Faster with a New CFD Workflow

On the Le Mans raceway, aerodynamics can mean the difference between first place and passing the checkered flag with the middle of the pack. Ferrari Competizioni GT has opened a new partnership agreement to use Ansys’ computational fluid dynamics (CFD) software to further optimize the performance of its racing cars.

Every two or three years, Ferrari Competizioni GT enters a 12-month development cycle to engineer a new GT racing car. Historically, this development cycle includes the CFD technology of Ansys Fluent.

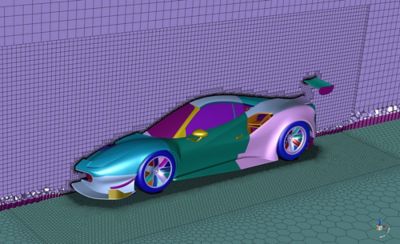

This Mosaic mesh is created by Ferrari

Competizioni GT. Mosaic meshing

workflows helped the team produce

three simulations in the time they once

produced one simulation

This year, the engineering team chose to use Ansys’ Mosaic-enabled Poly-Hexcore CFD meshing technology.

“With Mosaic technology and Fluent’s single window workflow, our team runs three times as many simulations in the same amount of time,” said Ferdinando Cannizzo, Ferrari Competizioni GT's Head of GT Racing Car Development.

The Benefits Mosaic CFD Meshing Brought to Ferrari Competizioni GT

Mosaic meshing solves Ferrari Competizioni GT’s need to create a transition zone between a fine CFD mesh, near the racing car’s surface, and a coarser mesh, within the fluid bulk.

Mosaic meshing simplifies the transition from fine to coarse meshes.

This Mosaic mesh is created by Ferrari Competizioni GT

Traditionally, this transition zone is made up of nonconformal interfaces or tetrahedral meshes. However, these methods can create meshes with large cell counts and slow performance.

Mosaic meshing, however, connects disparate meshes using general polyhedral elements.

“Mosaic-enabled meshing is making a considerable impact on our aerodynamics designs — letting us achieve improved accuracy using far less cells and solving in half the time,” said Cannizzo.

The team also took advantage of automated workflows within Fluent. These workflows reduced the hands-on work to create a CFD simulation and took advantage of parallel high-performance computing (HPC) to mesh the geometry.

“Ferrari Competizioni GT racing cars represent the pinnacle of commercial car racing and we are proud to help them engineer new aerodynamic designs leading to more victories on the track,” said Sandeep Sovani, director of the Global Automotive Industry at Ansys. “Teams are always looking for performance advantages and Mosaic meshing accelerates all stages of the simulation workflow, answers design questions sooner to maximize production efficiency and supports tight developmental timelines.”

To learn more about Mosaic Meshing, read: How to Build a Computational Fluid Dynamics Mesh for Fast and Accurate Simulations.

To learn how to take advantage of parallel processing to create a CFD mesh, read: How to Use Parallel Processing to Generate a 3D Mesh for CFD on an HPC.