-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

June 23, 2022

Deep Learning Is Poised to end the Trade-off Between Speed and Fidelity

While we’d love to “have it all,” all the time, the reality is that life is filled with trade-offs. One of the trade-offs Ansys customers make every day is between simulation speed and fidelity. Recognizing that every product development team has its own priorities, Ansys has worked to clarify and simplify this trade-off — and offer a range of solutions that deliver specialized, user-specific benefits.

On one hand, Ansys’ flagship physics-based solvers, including Ansys Mechanical and Ansys Fluent, are designed to capture incredibly complex problems such as turbulence and vibration with an extreme degree of accuracy. Engineers can apply multiple physics, look at transient time scales, perform system-level analysis, and otherwise fully replicate a dynamic working product in the field. Obviously, these full-scale simulations are numerically large problems that, despite quantum leap improvements in hardware and software, take some time to solve.

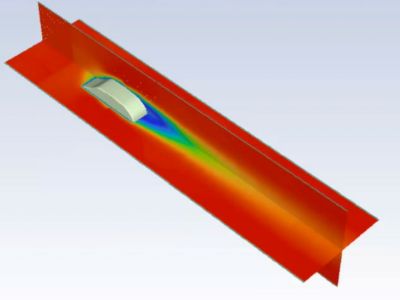

On the other hand, Ansys offers early-stage simulation solutions, such as Ansys Discovery, that replicate physics-based problems at a lower level of fidelity — but deliver much faster results. At the beginning of the design cycle, development teams can take a quick look at a rough estimation of product performance and make preliminary decisions about the overall design direction. They can test various scenarios and innovate freely, knowing that the final design will be subjected to more rigorous analysis later in the development cycle.

As thousands of Ansys customers worldwide can attest, both high-fidelity and lower-fidelity simulation solutions add significant value. Each approach has earned its place in the product development process and has been proven to deliver a high return on investment. However, today Ansys customers need to make a general choice between a fast, lower-fidelity model or a slower, more physically accurate model.

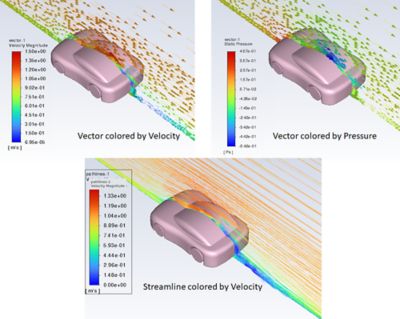

Simulating external flow over a car showing velocity and pressure.

The Next Frontier: Accelerating Complex Analysis

To offer our customers the best of both worlds, Ansys is continuously innovating to eliminate any trade-offs. We believe a future generation of Ansys software may be able to deliver both extremely high speed and extremely high fidelity simultaneously, in a single solution. And we believe the answer to delivering this powerful combination of benefits lies in applying deep learning (DL), coupled with solvers engaged in the loop.

At the heart of engineering simulation are partial differential equations (PDEs). Ansys physics-based solvers spend the bulk of their time modeling and solving the underlying conditions for these problems, including defining geometries, boundary conditions, and constraints. In the past, it has been difficult to accelerate this process because of the volume of computing required for fine meshes and complex geometries that need to be solved from scratch.

However, DL techniques may hold the answer. The Ansys research and development team is exploring the potential use of DL to solve high-dimensional problems in simulation space much like the problems in computer vision space. We are looking to reduce the dimensionality of numerically large, complex 3D or 4D models using DL techniques before coupling them with solver-in-the-loop to make accurate generalizations across many unseen geometries, boundary conditions, or loads. We recently published a paper on this novel DL-based approach, called Composable AutoEncoder Machine Learning Simulation (CoAE-MLSim).

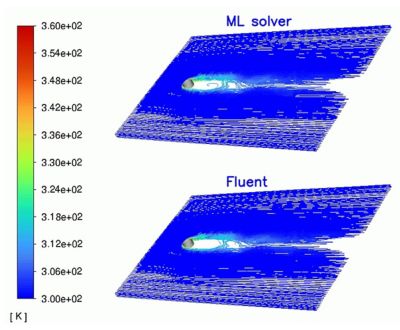

Simulated temperature flow over a cylinder

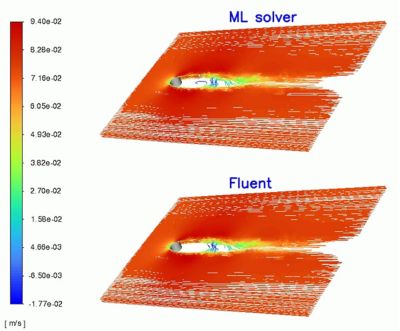

Simulated velocity flow over a cylinder

Capture Data Locally; Solve Globally

How do we think CoAE-MLSim will benefit Ansys customers? This innovative technique will help us combine the speed and ease of lower-fidelity solutions like Discovery with the robust, fully compliant, high-fidelity modeling capabilities of our flagship solvers.

CoAE-MLSim looks at local subdomains within a larger geometric mesh. These subdomains consist of a group of pixels in 2D or voxels in 3D — perhaps eight or 16 cells in each spatial direction. Advanced DL algorithms allow CoAE-MLSim to “learn” to perform physics-based solutions on these local subdomains, then learn the rules of how multiple subdomains are connected. This yields a set of locally connected solutions across a larger area of the mesh. Finally, iterative DL algorithms enable CoAE-MLSim to establish local consistency across all groups of subdomains in the entire computational domain.

Adopting the CoAE-MLSim approach means that Ansys software solutions will be “trained” to look at small, localized areas of a geometric mesh and accurately infer results for the entire mesh at a very high level of fidelity. In doing so, they will be backed by iterative deep-learning algorithms, but they will also couple solvers powered with traditional PDE modeling capabilities that have always been at the heart of Ansys solutions such as Mechanical and Fluent.

These next-generation solutions will accelerate the convergence of geometric models, as well as improve the accuracy and generalizability of the PDE results. In other words, they will eliminate the historical trade-off between high speed and high fidelity, enabling Ansys customers to enjoy both in one solution. Even better? The addition of deep learning means that, as Ansys customers apply simulation software to their own unique physics-based problems, the DL-enabled solvers will continue to learn, delivering more accurate and faster results over time.

Looking Toward a Smarter Future

We’ve already seen artificial intelligence (AI) and machine learning transform many aspects of our personal and professional lives. At Ansys, we’re excited about their potential to revolutionize the foundational capabilities of our solutions, such as their ability to model and solve PDEs.

While we’re not there yet, every day we’re exploring the possibilities of AI and ML to help our industry-leading solutions deliver even greater customer value. We hope you’re also excited about this forward-looking vision of the future of engineering simulation.