-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

May 9, 2022

Collaborative Ecosystems Enable Startup Innovation

What inspires us to new build companies, create new products, or find new solutions? What drives us to look for that next big idea just around the corner? It’s our passion for building things — our belief in possibilities and the inspiration we draw from others to make our dreams realities. The importance of building ecosystems, or environments, around these aspirations is central to this notion. At Ansys, we have created a collaborative ecosystem where simulation takes center stage: the Ansys Startup Program.

Simulation enables startups to take uninhibited technological leaps to make their innovations realities, disrupt entire industries, and change the world. With the help of the Ansys Startup Program, young companies are developing entirely unique products using simulation as their key driver for success. The Simulation World Startup Track “If You Build It” showcases startups from a wide range of industries and how their innovations are changing the world. Let’s look at a few of those startups presenting at Simulation World.

Lightyear Uses Solar Power to Democratize Clean Mobility

The Lightyear One solar-powered electric vehicle (EV) concept

One of the biggest challenges of electric vehicle (EV) technology is building the infrastructure needed to support it. EV driving ranges can be anywhere from 100 miles to 520 miles1, which is great — until you have to recharge the battery. Without a network of charging stations in place to support them, battery-powered vehicles can only travel so far. Lightyear Co-founder and Chief Technology Officer Arjo van der Ham wants to change all that with the development of ultra-efficient, solar-powered family cars that incorporate roof- and hood-mounted solar panels into a five-seater electric vehicle design.

“Eco-conscious drivers are not worrying about how fast they can go from 0 to 100 kilometers per hour,” says Andrea Carpi, Structural Lead Engineer at Lightyear. “They are looking for efficiency — getting the most range from a clean power source without having to stop frequently to recharge.”

Lightyear evolved from Solar Team Eindhoven, a student engineering team that won multiple editions of the Bridgestone World Solar Challenge for an eco-friendly, self-charging concept that runs on solar power during the day, then pivots to battery power at night and was designed using simulation. Their unique design eliminates the need for frequent stops to refuel or recharge. At Simulation World, van der Ham will offer more details about the Lightyear One, expected to launch this year. The EV receives approximately 70% of its energy demand from the sun, making it twice as efficient as other alternatives in the automotive space.

Synhelion Drives Carbon-Neutrality with Solar Fuels

As this startup proves, there’s more than one way to harness the sun for cleaner mobility. Dr. Lukas Geissbühler, Head of Thermal Systems at Synhelion, tapped into the Ansys simulation ecosystem to develop technology that uses solar heat to convert CO2 into synthetic (solar) fuels. The clean energy company evolved from the Swiss Federal Institute of Technology in 2016 to decarbonize transportation.

“Ansys’ CFD (computational fluid dynamics) and FEA (finite element analysis) simulation allows us to develop, test, and validate extremely complex technology to create sustainable solar fuels,” says Geissbühler. “Particularly, in developing our solar receiver, we needed sophisticated and predictively accurate software and Ansys delivered. Thanks to Ansys’ software, we could reduce prototyping time and build our first industrial receiver more quickly.”

Solar fuels have the potential to replace all types of fossil fuels, as they are economically viable and fully compatible with existing global infrastructure. Synehlion’s efforts will enable an unprecedented number of industrial processes, such as fuel production and cement manufacturing, with solar heat. During his Simulation World presentation, Geissbühler will explain how Synhelion’s solar fuel technology works and how his team uses multiphysics simulation to overcome design challenges, predict future outcomes, and reduce prototyping time.

X1 Wind Pushes the Boundaries of Offshore Wind Harvesting

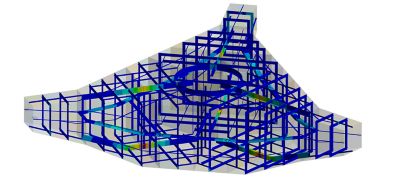

Interior view of X1 Wind’s Tension Leg Platform (TLP) floater, to which the mooring lines are connected.

Wind harvesting requires a lot of space, inspiring some harvesting operations to move offshore to fixed installations in shallow waters along coastal areas. Yet 80% of the world’s offshore wind potential lies in deeper waters2, inspiring Carlos Casanovas, CTO and Co-Founder of X1 Wind to build an innovative floating wind platform. Just how much potential are we talking about? Approximately 120,000 gigawatts (GW), enough to meet the projected global demand for electricity 11 times over in 20403.

The X1 Wind platform features a floating tripod design anchored to the ocean floor by a tension leg platform (TLP) mooring system, enabling the wind turbine to pivot with the wind to capture more energy. Ansys provided X1 Wind with the tools needed to optimize the structural design through weight reduction and achieve a lightweight floating platform suitable for energy harvesting in open waters. At Simulation World, Casanovas will share how simulation enabled a lighter, more efficient energy harvesting design that addresses the logistical challenges of turbine installation in open waters.

“We need to try to make our floating wind structure reliable and strong enough to remain competitive, because with renewable energy, it's all about the final cost of energy,” says Casanovas. “If your floating design is very heavy and expensive to build, you will not be very competitive, so structural integrity is a really fine line for us. It’s important to have the right simulation tools so that you can do all the optimization that you need to do, and Ansys checks all the boxes.”

Connect Everything Aerospace Makes Space Travel Personal

The recent privatization of space exploration opens up a world of untapped possibilities for related products and services, from launching satellites, to transporting goods, and even space tourism. Ewan Craig, Chief Engineer and Managing Director at Connect Everything Aerospace (CEA), an Ansys Startup Program beneficiary, is 3D printing rocket engines to democratize space travel.

Craig pursued the idea after he discovered an aerospike engine concept from the 1960s. Intrigued by the prospect of a redesign, Craig found that the only way to produce a viable engine design was through additive manufacturing, or 3D printing. He says the engines are faster to deliver, cheaper to produce, more powerful and lighter than anything before, and represent the future of spacecraft propulsion in the 3D-printed single-piece aerospike.

“On October 11, we officially produced the world’s first single-piece rocket engine, 3D printed by our partner Velo3D,” says Craig. “… We’re planning a test flight in 2022 and, if it works, that will be the first time one of these engine designs from the 1960s actually ever got off the ground. I’m excited and I’m also confident. My Ansys simulations say it’s going to work, and so I expect it to work.”

Perhaps the most compelling part of Craig’s story is how his foray into space began as a backyard inventor who was simply curious about reviving a concept for a vintage rocket engine. He’ll speak about it during Simulation World, as well as the events leading up to the upcoming test flight.

Don’t Forget to Register

If you’re intrigued by what the future holds and how startups are stepping up to innovation with simulation, be sure to register for Simulation World 2022. Add some sessions from the “If You Build It” track to your personalized agenda so you can hear from Lightyear, Synhelion, X1 Wind, CEA, and others.

1. “EV Range. Everything You Need to Know,” Car and Driver, February 14, 2022.

2. “New GWEC Report identifies floating offshore wind’s critical role in long term decarbonization efforts,” GWEC, March 11, 2022.

3. “Offshore Wind Outlook 2019: World Energy Outlook Special Report,” International Energy Agency (IEA), 2019.