-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

September 23, 2017

Bladeless Propulsion System Developed to Replace Propellers

For over 100 years, propellers have been the propulsion method of choice for aircraft, helicopter, and boat manufacturers. With the rise of multi-rotor technology, the limitations of this ancient method of propulsion have placed a glass ceiling on emerging industries such as drone delivery and “flying cars.” Besides the obvious safety issues, the faster that a blade rotates the more inefficient it becomes at transferring energy into thrust. A key reason for this upper limit on economies of RPM is that the faster a blade spins, the more prominent the vortex geometry becomes in the mass flow, which is parasitic to propulsion. This constrains both payload and range.

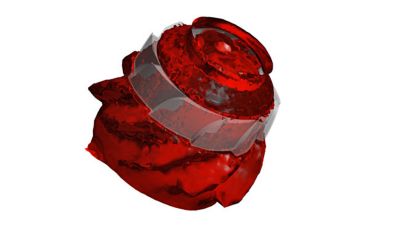

ISO, Side, and Top view in CFX - CFD-Post of velocity Isosurface of ducted counter-vortex radial impeller simulation.

Solution with Bladeless Propulsion System

Mohyi Labs has invented a “bladeless” propulsion system that has the potential to change the game. The technical name is ducted counter-vortex radial impeller propulsion. When a radial impeller rotates freely or inside a normal duct, the flow geometry resembles a strong vortex pattern. While radial impellers provide substantial airflow, because of this vortex pattern they provide virtually no thrust. By combining a radial impeller with Mohyi Labs’ ducted counter-vortex geometry, we convert that airflow into thrust by counteracting the vortex and redirecting the flow downward.

The All-Seeing Eye

Though the “guess and check” method may have been sufficient for establishing proof of concept, airflow is an inherently complex medium to work with. Mohyi Labs is using Ansys as our all-seeing eye to eliminate tedious guesswork. In my experience, 90 percent of the solution is understanding the problem. Using Ansys CFX tools, we can isolate every airflow characteristic in order to paint a detailed picture. Using this big picture, we can finally tease out the different layers of complexity and solve one problem at a time.

The Feedback Loop

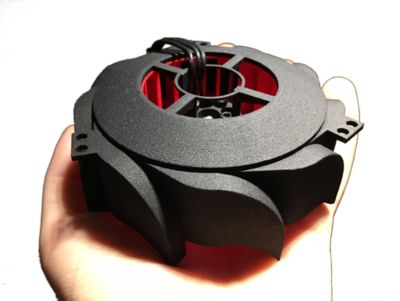

One does not simply make a bladeless propulsion system. We have come a long way since our original design. Ansys not only allowed us to visualize parasitic vorticies in the flow geometry, but it also precisely isolated discrete velocity regions and let us study the pressure distribution across thrust surfaces. This has given us a virtually instantaneous feedback loop where we can quickly experiment with curvatures, angles and chamber dimensions.

Optimization involves countless iterations to achieve peak performance characteristics. Normally this would be an arduous process as physical prototypes are expensive and time consuming to fabricate; expensive testing equipment must be setup for each prototype; and the raw output data must be processed. Using the streamlined and intuitive Ansys Workbench graphical user interface, I can quickly modify any element of the simulation study, including the geometry itself, and generate data. Parametric studies further accelerate this process by automating the analysis of certain variable parameters.

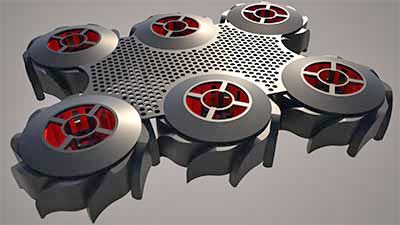

The Product

The first use case is a delivery drone. Since a bladeless drone can’t cut someone, it is able to fly at shoulder level and below during last mile deliveries in populated areas. This removes the possibility of the drone and the package falling on someone in the event of a system failure. With the help of the Ansys Startup Program, Mohyi Labs hopes to change the game by bringing a safe and efficient delivery drone to densely populated areas.

Bladeless Drone embodiment of ducted counter-vortex radial.

Once perfected, we will scale up the technology for autonomous personal aerial transportation. This will be a massive undertaking, but with the help of Ansys, the future is closer than you think.

Prototype of single bladeless thruster.

Self-flying car embodyment of counter-rotating ducted counter-vortex radial impeller technology in Flight Mode over the city.