-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

October 1, 2021

A Formula for Success

Almost as soon as the first automobiles appeared in the 1880s, enthusiasts began modifying them for racing. Open-wheel racing became a sanctioned professional sport very quickly thereafter on both sides of the Atlantic and has evolved into a globe-spanning industry. Whether the cars are circling oval tracks in IndyCar or road-course circuits in Formula 1, they are the product of years of engineering by large teams trying to wring every last horsepower and newton of downforce out of their machines to give their drivers the best chances to win while staying within the design rules and budget caps.

2018 Formula Student car from Team Bath Racing (TBR).

Student Competition History

For many aspiring engineers, one avenue toward pursuing a career in the auto industry has been through their participation in the main international open-wheel competitions targeted to university students. In North America, Formula SAE began its competitions in 1981, and is organized by SAE International – formerly the Society of Automotive Engineers. SAE now hosts multiple Formula SAE events globally with its main showcase at the Michigan International Speedway near Detroit. Student teams design and fabricate a new vehicle for each competition year. In a typical year, the teams square off in three static events, including cost analysis, business presentation and engineering design, and five dynamic events, including skidpad, acceleration, autocross, endurance and efficiency. The UK-based Formula Student competition emerged in 1998 with very similar rules as Formula SAE and hosts its main event at the Silverstone Circuit in central England.

The use of Ansys simulation software by student teams debuted in the 1990s, with early adopters first using the Ansys structural analysis package to model the stresses, stiffness and vibration modes on different elements of the vehicle chassis. Beginning in 2012, Ansys began officially sponsoring student teams by providing no-cost access to its suite of structural, fluids electromagnetics and high-performance computing tools. Additionally, the teams have access to free software training courses and to the Ansys Learning Forum for technical support. Of the several hundred teams from universities around the world competing in Formula SAE and Formula Student events, over 150 of those teams are benefitting from an Ansys sponsorship, including the University of Bath and IIT Bombay, as CAE tools are now widely used as part of the teams’ design processes.

IIT Bombay Racing’s E-12 electric vehicle, winner of the Formula Student 2020 Engineering Design competition.

Team Bath Racing

In the internal combustion category, Team Bath Racing from the University of Bath has been competing in Formula Student events since 2000 and has been consistently ranked as the top UK team for many of those campaigns. By having to create a brand-new vehicle from scratch each year, the team is limited by both the available time and funding. It has been crucial that any simulation software be easy to use and capable of producing accurate results – no matter the size of the component or model.

With both Ansys Mechanical and Ansys Fluent in its arsenal, the Bath students have been able to use the software’s wide range of simulation features to develop and test ideas effectively and reliably while reducing costs by reducing the need for prototyping and wind tunnel testing. Analysis in Mechanical ensures that the vehicle components comply with the Formula Student rules and can withstand the stresses and conditions of the competitions. Fluent simulations have enabled the team to produce year-over-year improvements in the aerodynamics package. Most recently, this was showcased through the development of new chassis winglets that redirect flow back towards the ground, increasing the rear and side wing downforce by 11% and helping propel Bath to win the overall static events at Formula Student 2020.

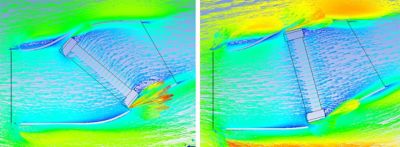

Visualization of airflow through the radiator at higher (left) and lower (right) angles of inclination. Porous media modeling was used to compute the flow rate through the radiator core and the drag at the different inclination angles.

IIT Bombay Racing

At the Indian Institute of Technology (IIT) Bombay, student teams have been competing in the Formula SAE and Formula Student events since 2007. For the Formula Student 2020 competition, the team’s entry was in the electric vehicle division, and they used both Ansys Mechanical and Ansys Fluent to help optimize different aspects of the design.

On the structural side, the development of a lightweight mounting structure for the rear wing was a challenge due to the position of the wing relative to the chassis. With Ansys Mechanical, the IIT Bombay team performed a static structural simulation on the first design iterations to visualize the stress contours on the wing mounts. The next step was a topology optimization analysis, where the students defined the targeted exclusion areas and weight-reduction goals. After making geometry changes based on the optimization study, the final design ended up being 40% lighter than the initial design while still meeting the required safety factor.

Initial design of IIT Bombay’s wing mounting structure in Ansys Workbench (left), followed by results from topology optimization and the final design (right) reducing weight by 40%.

For fluid dynamics analysis, the team found Fluent to be indispensable to the process of designing the cooling system for the vehicle’s battery cells. The students wanted to find the best angle of inclination of the radiators to balance the airflow through the core and the resultant drag on the vehicle. Another challenge was uneven airflow within the accumulator leading to the creation of local hot spots. The IIT Bombay team was able to assess the flow rate and drag at different angles of inclination. They used Fluent’s porous media simulation capability to accurately model the radiators and the flow rate through them. With their final design, the team reduced the overall size and weight of the radiators by about 25%and reduced the cell temperature by 15%. Combined with the results from the structural analysis, these design improvements helped IIT Bombay Racing win the Engineering Design event at Formula Student 2020 and place fourth overall among electric vehicles.

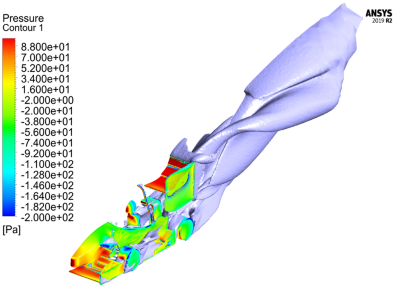

Full car simulation of airflow over TBR’s 2021 car using Ansys Fluent.

Formula Student UK Champion

“We are currently manufacturing and testing our latest car E-12,” says Saksham Garg, chief mechanical officer, IIT Bombay Racing, “the design of which won the FSUK 2021 overall championship title, the Engineering Design Competition at both FSUK 2021 and FSUK 2020, and the FSEV Concept Challenge 2021.”

Garg credits Ansys for playing a pivotal role in these wins by providing a comprehensive suite of engineering tools.

“With the use of Ansys software, our team was able to reduce the weight of the rear wing mounting structure by 40%, reduce the weight of our radiators by over 24% and cell temperature by 15%,” Garg says. “This improved our team’s overall race car for the Formula Student competition. Using Ansys software not only helped the team overall but also improved our technical skillset and practical experience, preparing our graduates for their future careers in industry and academia.”

Looking Ahead

In the 2020 events, the governing bodies moved the competitions to a virtual format to accommodate COVID-19 global travel restrictions. For 2021, dynamic events returned to the tracks in July for both Formula SAE and Formula Student. Adjusting to a virtual format with limited ability to have the design groups meet in person further highlighted how critical simulation software is to the design process when physical testing is limited or not available. Throughout these competitions, the IIT Bombay and Bath students, along with all the Ansys-sponsored teams, are gaining valuable experience on real-world projects – experience that is particularly sought after in the auto industry – as they make their way into the professional engineering and design communities.

To learn more about Ansys student team sponsorship visit ansys.com/teams.