-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Vehicle Powertrain Simulation Software

Engineer high-performance, fuel efficient and environmentally friendly powertrain design with simulation.

Optimizing Vehicle Powertrain Performance With Simulation

While the transition to electric powertrains accelerates, optimizing more traditional internal combustion engine-powered vehicle powertrains is critical to the ongoing improvements in fuel efficiency and required environmental performance. Perfecting powertrain design through simulation offers the only way to deliver performance, fuel efficiency and environmental goals in one package.

-

Internal Combustion Engine

-

Transmission

-

Fuel Systems

-

Exhaust System and Aftertreatment

-

Electric Powertrain

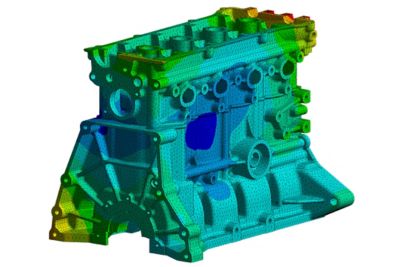

Internal Combustion Engine

Ansys IC specific workflows with integrated multiphyscs and ready-to-use fuel models deliver fast, accurate simulations to determine combustion efficiency, spray performance, fuel composition and emissions trade-offs and operating conditions.

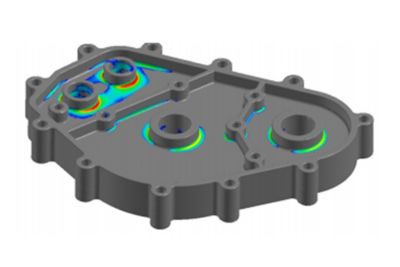

Fuel Systems

Simulations including complex spray models with primary and secondary breakup, evaporation and wall films —combined with fluid structure interaction and motion—enable the prediction of fuel spray targeting, pump efficiency and pump noise.

Electric Powertrain

Learn how simulation and Ansys play a critical role in accelerating the electric mobility revolution.

Transmission

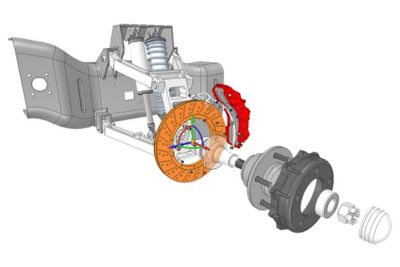

Comprising dynamic analysis, gearbox motion, gear tooth stress, NVH and lubrication analysis, simulation enables the prediction of fatigue life, natural frequency and vibration modes, viscous and thermal losses and identifies regions of poor lubrication.

Exhaust Systems and Aftertreatment

Ansys simulations enable the determination of reliability and durability of designs that achieve the required noise and emissions regulations, including conjugate heat transfer, structural analysis and chemistry models.

Featured Products

In battery-electric vehicles, the efficiency of the powertrain has a big impact on driving range and performance.

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。