-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS ADVANTAGE MAGAZINE

January 2021

Good Vibrations

By Chao Yu, Senior Project Engineer, Corning Inc., Corning, U.S.A., and Hui Liu, Technical Support Engineer, Ansys

From consumer electronics to medical devices, many smart-product applications depend on transmitting acoustic vibrations effectively through glass. The challenge? Making the glass thin enough to accurately transmit ultrasound waves, yet structurally strong enough to withstand daily use. Corning engineers rely on multiple Ansys solutions to balance acoustic and mechanical performance as they develop smart, innovative glass solutions.

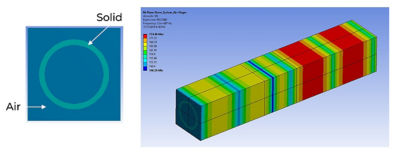

One consumer application involved the placement of a ring-based load on the glass surface, with the load distributed across the glass in a non-uniform pattern. Ansys software easily enabled the required simulation and analysis.

Already a central component of many consumer products ― from cars and planes to residential windows ― glass plays a critical role in many of today’s smart products. Consumer electronics often feature displays and touchscreens that not only relay information but also serve as user controls. Medical devices frequently rely on glass to display, communicate and guide the results of advanced imaging procedures.

While smart-product applications are diverse, many rely on the ability of glass to accurately transmit acoustic ultrasound waves from one side of the glass ― the user or “control” side ― to the other side, where a receiver gathers and processes the signal.

In these applications, the glass substrate must be thin enough to accurately transmit ultrasound vibrations, thick enough to withstand daily use and structurally strong enough to withstand unexpected impacts. In addition, to keep up with consumer demand, it usually must be as lightweight as possible.

The engineering team at Corning is challenged daily to balance these competing requirements as it develops advanced glass solutions for smart-product applications. Engineers must deliver proven, accurate solutions, but they must do so quickly to meet customers’ ambitious launch targets.

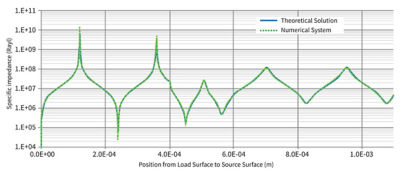

Corning engineers have successfully validated the Ansys model with theoretical solutions. Excellent agreement was obtained on acoustic-specific impedance across all layers.

Building on a Sound Record of Success

For decades, Corning engineers have relied on simulation solutions from Ansys to meet these types of complex product design challenges. For example, the Corning development team has helped automotive customers significantly reduce glazing weight while maintaining acoustic noise levels inside cars by developing new technical glasses, based on Ansys-enabled aerodynamic and vibroacoustic analysis (see “A Window into Automotive Noise,” Ansys Advantage V12 I1).

To solve the problem of effectively sending ultrasound waves through glass, the team applies Ansys Mechanical to assess acoustic loading, vibration, structural strength, deformation and a range of other mechanical aspects of glass performance.

To ensure that these simulations are conducted quickly and are integrated with other product development processes, the team uses Ansys Mechanical Acoustic. This solution enables Corning to develop customized, unified simulation workflows that integrate all Ansys technologies and other engineering tools. The result is clearer and more accurate trade-offs, faster and better decisions, and enhanced employee productivity.

Minimizing Acoustic Impedance: A Case in Point

Recently, the product development team at Corning used the combination of Ansys Mechanical and Ansys Mechanical Acoustic to model and assess a new glass configuration for a customer-specific application. The glass structure was composed of an adhesive layer, sandwiched between two glass substrates. Corning engineers needed to simulate and predict how well the configuration would transmit acoustic ultrasound waves, with minimal loss.

This required the team to study the acoustic impedance of the new glass structure, or the resistance of the glass stack to transmitting ultrasound waves. For the specific customer application, any sound transmission loss would be disastrous, interfering with the end product’s core functionality. The engineers needed to evaluate both characteristic impedance (the intrinsic resistance of the material, across its entire surface) and specific impedance (a measure of the material’s resistance at certain critical points on its surface). Both types of analysis were needed to optimize performance.

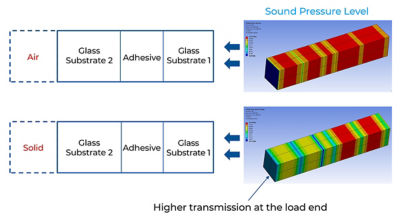

To replicate actual operating conditions for the final product, Corning engineers applied acoustic loads from both air and solid materials. As they examined the degree of impedance generated by different loads, the product development team was able to ensure accurate transmission and high acoustic quality in real-world use cases.

To determine impedance, a numerical model was constructed in Ansys Mechanical Acoustic; the model included a plane wave source with an exact ultrasonic frequency between 10 and 20 MHz, as well as the isotropic materials stack. The adhesive was treated as a solid; its elastic properties were considered during the impedance calculations.

To address any limitations or weaknesses in individual product layers, both component- and systemlevel models were developed in Ansys Mechanical Acoustic. While the system-level model only required engineers to define boundary conditions at source and load surfaces, the component-level model enabled engineers to define and study one substrate layer at a time. As engineers completed simulations for each layer, the impedance results became a boundary condition for each subsequent layer.

To test glass performance under a range of real-world operating conditions, a variety of acoustic loads were applied to the model. By varying acoustic pressure, acoustic velocity and power intensity during their simulations, Corning engineers could determine how impedance was affected by different loads. When used by consumers, the outer glass surface could be contacted by air, solids or a mix of both ― all of which are capable of producing acoustic energy. The development team needed to assess how this energy, whether applied intentionally or accidentally, might impact the product’s performance.

One special consideration was that the glass would need to respond appropriately, accurately and reliably to a ring-based load applied to its outer surface. This was related to the final product’s core functionality. This ring-shaped load might be distributed across the glass in a non-uniform manner ― yet the product had to respond reliably and uniformly. This made the problem more complex, as power intensity and impedance were no longer constants during the simulations. The Ansys solutions were easily able to accommodate this requirement and replicate the needed physical conditions.

Signaling a Smart Future

As Corning engineers calculated both wave propagation and acoustic impedance for the new glass product under diverse conditions, they were able to optimize its properties and minimize impedance by addressing any sources of resistance. By varying glass composition, material thickness and orientation, and other properties of the glass stack, engineers developed a final, optimized product that meets the customer’s demanding smart-product application.

The Corning team recognized that each glass assembly has a unique acoustic signature in terms of coincident frequencies and impedance. For a given ultrasonic frequency, the team was able to optimize the material attributes to maximize sound wave transmission through the glass assembly, as well as its return from the loading surface back to the signal-detection side of the glass.

This problem of accurately transmitting ultrasonic waves through a stacked-glass substrate was unique to this customer, but it typifies the sophisticated physics problems involved in smart-product design. As smart products continue to evolve, Ansys simulation allows Corning to tackle advanced customer challenges quickly and accurately, and to support continuous innovation and rapid product launches.

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。