Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

A power generation company enlisted Ansys Reliability Engineering Services (RES) to design and implement a thorough and accurate method for validating the reliability and robustness of a new flow-rate valve for their hydrogen fuel cell as quickly as possible.

Challenges

The company had experienced sporadic field failures of their gas flow-rate valves in their hydrogen fuel cell, requiring a new flow-rate valve to be implemented. Unfortunately, they did not have the flexibility to disrupt their energy operations to explore new technologies and evaluate suppliers. A new flow-rate valve would need to be qualified for reliability and implemented immediately to meet their clients’ needs.

Engineering Solutions

Approach: Step 1 — Construction Analysis and Design Review

Ansys RES performed a teardown and construction analysis along with a design review to identify high-risk components and areas of concern related to long-term performance. The risk assessment focused on the higher risk and critical-to-quality items, including travel range and speed with positional encoder, hysteresis, valve leakage, printed circuit board assemblies (PCBAs), and mechanical interfaces subject to wear-out within the drive train. Field data and maintenance history, application-specific environmental conditions and materials, fit/function of the design, and the assembly drawing and process were included in the comprehensive review.

Ansys RES provided recommendations for improvement against potential failure modes and mechanisms, including mitigation of:

- Thermo-mechanical fatigue with appropriate selection of PCBA staking material in terms of coefficient of thermal expansion (CTE) and glass transition temperature (Tg)

- Electro-chemical migration with elimination of observed flux and contamination on positional feedback element

- Wearout and performance issues with proper alignment and guidance of travel mechanism

- Performance issues with use of thread-locking components in drivetrain interfaces

Approach: Step 2 — Test Plan Development

Ansys RES developed a customized life test plan to verify the desired reliability and confidence levels for prospective replacement valves. This included gathering information about the application conditions and operating environment of the flow-rate valves and understanding the higher risk failure modes and underlying mechanisms. Next, Ansys RES utilized appropriate failure models to develop an accelerated life test (ALT) plan that imparted higher stress on the device relative to its operating environment to reduce time in test without introducing failure modes that it would not ordinarily see in the field. The accelerated life tests also incorporated functional performance checks for robustness. The reliability tests included:

- Mechanical cycling (accelerating contact wear, including the positional encoder and valve packing seals)

- Thermal cycling (accelerating solder joint and component fatigue due to differences in CTE among the materials)

- Humidity cycling (accelerating corrosive effects of condensing humidity on the actuator and interface clamp within the assembly while in storage and during any cumulative maintenance downtime)

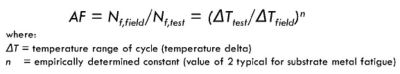

Figure 1. Coffin-Manson failure model used to determine acceleration factor in test

Approach: Step 3 — Reliability and Validation Testing

The results from the ALT performed on-site at the Ansys RES laboratory identified which valve models would perform sufficiently in the field environment for the desired lifetime at the prescribed reliability and confidence-level goals.

Figure 2. Mechanical ALT of flow control valves

Benefits

Data gathered from accelerated life tests performed by Ansys RES provided the client with invaluable information to support the critical process of replacing equipment while maintaining operations and ensuring the long-term deployment of field equipment. The client now employs the personalized test plan developed by Ansys RES, enabling them to expediently validate the reliability of new equipment and build confidence with their customers in the reliability of this critical fuel cell technology.

Erfahren Sie, wie Ansys Ihnen helfen kann

Erfahren Sie, wie Ansys Ihnen helfen kann

Kontakt

Danke für die Kontaktaufnahme

Wir sind hier, um Ihre Fragen zu beantworten und freuen uns auf das Gespräch mit Ihnen. Ein*e Mitarbeiter*in unseres Ansys-Verkaufsteams wird sich in Kürze mit Ihnen in Verbindung setzen.