Safe & Secure Systems

Dramatically decrease analysis efforts with efficient application of quality, safety, reliability and cybersecurity analysis methods at the system, item, software, hardware and PCB levels.

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Dramatically decrease analysis efforts with efficient application of quality, safety, reliability and cybersecurity analysis methods at the system, item, software, hardware and PCB levels.

High Level Features

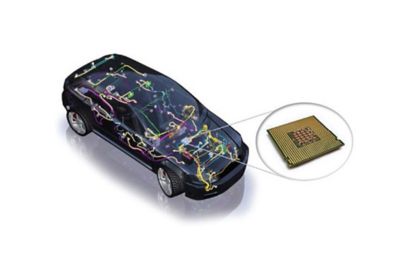

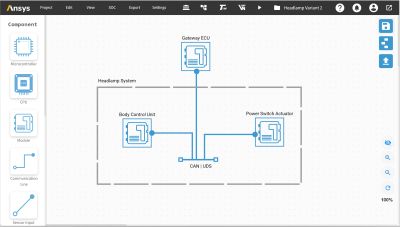

Ansys safety & cybersecurity threat analysis software facilitates model-based safety analysis, safety concept creation, safety management and cybersecurity assessment for safety-critical electrical and electronic (E/E) and software (SW) controlled systems.

Using this software, engineers can deliver safe and secure products, reduce time to market, maximize profit margins and comply with standards like ISO 26262, IEC 61508, ARP 4754A/ARP 4761, ISO 21448 and ISO 21434.

Dramatically decrease safety analysis for electronically-controlled safety related functions and accelerate time to market with state-of-the-art methods in the model-based environment of Ansys medini analyze.

July 2025

Introducing Ansys Medini Cybersecurity SE, a powerful new web-based tool designed to simplify your cybersecurity analysis process. Additionally, explore the latest upgrades to Ansys Digital Safety Manager and medini analyze for robust model-based system safety management.

The Ansys Safety Analysis software suite streamlines safety and security analysis, decreasing efforts and costs.

Ansys medini analyze for Cybersecurity delivers an easy-to-use modeling and analysis tool that ensures your electronics architecture — across its many connections and interfaces — is impervious to external attacks. Watch this impactful video to understand how you can replace your outdated tools and manual processes with the speed and automation of medini analyze to deliver safe and secure products, reduce time to market, maximize profit margins and comply with upcoming regulations surrounding cybersecurity.

Dramatically decrease safety analysis for electronically-controlled safety related functions and accelerate time to market with state-of-the-art methods in the model-based environment of Ansys medini analyze.

Safety is a crucial property for many products, especially in the aerospace and defense industry, essential to obtaining the necessary certification. To identify appropriate safety requirements early in the development process and to be able to demonstrate their fulfillment by design, safety analysis must be well integrated into the system development process in all phases. In a model-based approach that is usually highly iterative, it's a great benefit to base the safety analysis on models. This allows us to deal with changes quickly and always have up-to-date analysis to guide development decisions.

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.