-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

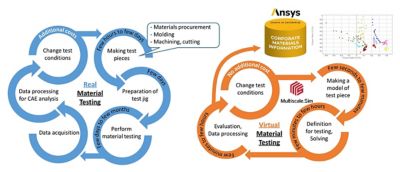

Have you ever thought about how new materials are tested and optimized before they become part of the products that we use daily? It's not as simple as it might seem. Traditional methods involve a lot of physical testing, which can be costly and time-consuming. But what if we could do most of this testing using computer software? That's where virtual material testing comes into play, which could revolutionize how we develop and optimize composite materials.

Why Virtual Materials Testing?

Imagine you’re tasked with designing a new lightweight and strong material for an aircraft. Traditionally, you'd have to create numerous physical samples and test them one by one. This process is not only expensive, but also incredibly time-consuming.

For example, take creep testing — which is used to measure how a material deforms under a constant load over time — or fatigue testing, which involves repeatedly applying and removing a load to see how the material reacts to it. Depending on the material and test conditions, it could take several days to several years before the test piece finally gives way.

No industry can wait that long.

Virtual materials testing enables us to simulate these tests within a few hours, if not minutes, using computer models. And better yet, researchers can repeat the same test or change test conditions with a click of the mouse, and sometimes the process can even be automated. This approach not only cuts down costs, but also speeds up the development process.

Multiscale.Sim add-in software for the Ansys Workbench platform can perform virtual material tests and provide homogenized materials information to create large material databases for Ansys Granta MI software.

The Role of Data in Materials Development

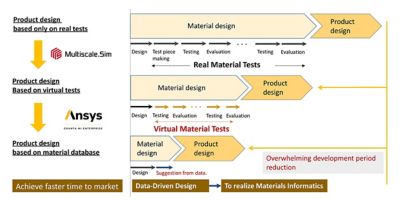

Data science has become a buzzword in many industries, and materials science is no exception. Emerging techniques such as "materials informatics" or "data-driven design" requires large amounts of materials data to train their artificial intelligence (AI) models. However, when it comes to composite materials, we often don't have sufficiently large materials databases, and physical testing usually can’t provide this much data fast enough.

This is where virtual materials testing can come to the rescue.

It uses finite element modeling (FEM) to create a detailed computer model of a material, which can be used to predict materials behavior under different conditions. This method, known as homogenization, eliminates the need for extensive physical tests and provides enough data for reliable computer simulations.

From Data to Design: The Process

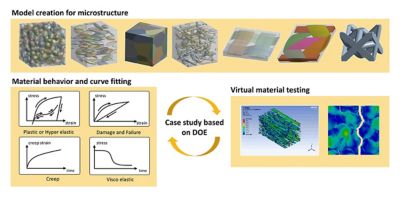

Below is a simplified version of how virtual materials testing works.

Virtual materials testing, explained

- Model creation: A finite element model that represents the microstructure of the material is created. This step involves defining the material's geometry and properties at a small scale.

- Virtual testing: Next, a series of virtual tests are run on this model. These tests simulate different conditions the material might face in the real world.

- Data analysis: The results from these tests are then analyzed to determine the material's macroscopic properties. This information is crucial for understanding how the material will behave in real-world applications.

- Optimization: Using the data, you can tweak the material's design to optimize its properties. This might involve changing the material's composition or its microstructure.

- Database integration: The data collected from these virtual tests is stored in a comprehensive material database, like Ansys Granta MI materials intelligence platform. This database not only stores the properties of the materials, but also enables easy access and visualization.

Overcoming Challenges to Virtual Testing

While virtual materials testing offers many benefits, it's not without its challenges. One of the main hurdles is the need for accurate and comprehensive materials data to start with. Without this data, even the best simulations can produce unreliable results. That's why building a robust materials database is crucial. Additionally, integrating these databases with simulation tools like Granta MI software ensures that the data is easily accessible and usable.

An integrated workflow between Ansys software and Multiscale.Sim, an add-in tool for multiscale analysis and simulation of composites developed by CYBERNET in Japan, provides a solution to overcome these challenges.

This workflow enables users to create material databases and facilitate parametric studies to develop new or optimize existing materials.

Multiscale.Sim software is embedded in the Ansys Workbench platform and includes coupling with various Ansys applications such as Rocky, Granta MI, and LS-DYNA software, enabling support for multiphysics problems. It provides unique capabilities for material simulation, including homogenization of thin plates with equivalent stiffness in bending and torsion (B and D matrix), and multiscale analysis of high-end nonlinear material problems such as creep, viscoelasticity, and failure. It also enables advanced nonlinear virtual material testing in Ansys Mechanical Workbench, such as delamination at material interfaces and crack propagation in the matrix phase.

Ansys also offers a native solution for multiscale homogenization through its advanced Material Designer tool. This powerful feature enables users to model Representative Volume Elements (RVEs), define material properties, perform finite element analysis virtually testing the microstructure, and compute homogenized material data seamlessly within the Ansys environment. The Material Designer tool streamlines the entire process, providing accurate and efficient multiscale material analysis tailored to engineering applications.

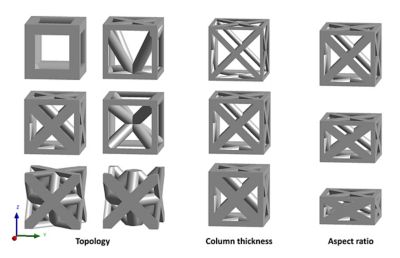

Lattice Structures

Lattice structure is an important area in material science. These structures are incredibly lightweight and are called metamaterials because they often have unique properties not found in traditional materials. By using additive manufacturing, you can create complex lattice structures that significantly alter the material's macroscopic properties. But testing these intricate designs physically would be a nightmare. Virtual materials testing enables you to explore these designs thoroughly and efficiently.

Overview of micromodels for typical lattice geometry parameters. Multiscale.Sim supports 13 different lattice topologies and capable of creating microstructure models automatically using readily available templates.

Discover the Real-world Applications of Virtual Testing

One fascinating application of virtual materials testing is found in the field of biomedical engineering — specifically in the creation of artificial bones. Naturally found biocompatible materials often fail to replicate the complex structure and properties of human bone. Therefore, biomedical engineers usually rely on metamaterials that are engineered to be both lightweight and strong.

Manufacturing artificial bones involves advanced 3D printing techniques and employes a lattice structural design for its unique weight distribution capabilities. Researchers design and optimize lattice structures using metamaterials that closely mimic the behavior of real bones. This innovation holds promise for improved medical implants that are more durable and better integrated with the human body. Similar applications are also increasing in other industrial products.

Due to the complexity of this process and the high degree of freedom in creating countless numbers of different structural designs before finding the ideal combination of materials, researchers tend to leverage on virtual testing. It enables them to play around with multiple design options within a short period of time.

Explore The Future of Materials Design

The future of materials design lies in the hands of virtual testing, and these technologies continue to evolve by leveraging the power of FEM and integration with advanced data management systems. This evolution will enable faster development cycles and more sophisticated material designs, ultimately leading to product innovation and sustainability in different industries. Whether it’s creating lighter aircraft components or designing better medical implants, the possibilities are endless.

So, the next time you hear about a breakthrough in material science, remember that there’s likely a lot of virtual testing making it all possible.

To learn more, download the case study “Building and managing a database of lattice structures using virtual materials testing and finding optimal design using neural network trained by material database.” You can also watch the on-demand webinar “A Faster Way to Develop and Optimize Materials.”

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.