-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

The Institution of Mechanical Engineers (IMechE) is an organization committed to developing and supporting the world’s current and upcoming mechanical engineers in creating solutions to global challenges. To motivate upcoming engineers, IMechE hosts an annual competition presented to engineering students from university technical colleges (UTCs) and universities in the United Kingdom: the IMechE Design Challenge.

In 2022, Ansys partnered with IMechE to serve as an industry partner, later creating the Ansys Simulation Challenge within the IMechE Design Challenge competition in 2023.

The IMechE Design Challenge exposes students to real-world engineering problems from beginning to end stages in a time-constrained window. The challenge comprises three stages: internal qualifiers at each college or university, regional finals, and national finals. The last two stages consist of multiple elements, including competition categories, such as presentation delivery, poster creation, and peer review.

From UTC to the final year of their undergraduate degree, students can enter the competition through either a curricular or extracurricular route in teams of three to six students. Curricular teams compete in the Design Challenge as part of their university’s academic curriculum, which often forms part of the degree assessment. Extracurricular teams are student-led and independently involved in the Design Challenge. Every year, the challenge looks a bit different — there is always a new project, often a new budget, and different rules to keep contestants alert.

With the Ansys Simulation Challenge, competitors were given a new opportunity to hone their skills. Teams were tasked with using Ansys simulation tools, such as Ansys Discovery 3D product simulation software, to model their submission using a structural, thermal, or fluid analysis. In using Ansys simulation, teams noted a reduction in engineering time and cost, not unlike in real-world scenarios involving simulation.

Creating Winning Designs With Simulation

In the Design Challenge, there are several categories that teams compete in throughout the day. However, the team that accumulates the most points overall is declared the overall winner of the Design Challenge competition.

We sat down with the 2024 Design Challenge and Ansys Simulation Challenge winning team to learn about its submission and how Ansys simulation helped secure four additional honors for it. The team won the main challenge, poster competition, design review competition, and overall national championship.

Daud Hassan, James Kwong, Taro Kuroda, Belkacem Bella, and Christopher Shiao are mechanical engineering students on Team C at University College London (UCL-C). In addition to their studies, jobs, internships, and extracurricular activities (such as chess and hockey), the one extracurricular that brought them together was the IMechE Design Challenge.

This wasn’t the team members’ first time competing in the Design Challenge. The team competed in its first challenge throughout the students’ first year of courses via the curricular route, but they decided to take the extracurricular route to submit their 2024 design, which featured a structural simulation using Discovery software.

Rules and Parameters

The 2024 IMechE Design Challenge task was to design and build a repeatable device that models an autonomous vehicle. The vehicle must move forward from the first target, touch a wall, reverse, and return to the first target, staying there for five to 10 seconds. Then, the vehicle must advance to a second target, which is placed 1 to 1.4 meters ahead — all within two minutes.

“We looked through the competition requirements and constraints and just tried to get an overall understanding of what the competition was this year," Hassan says. “Then we worked toward an initial design, creating a minimum viable product. Slowly, we began adding to that, improving the accuracy. Once we had that initial prototype, we started implementing improvements in cost and mass savings through the finite element analysis (FEA).”

Team C at University College London (UCL-C), the winner of the 2024 Institution of Mechanical Engineers (IMechE) Design Challenge and Ansys Simulation Challenge

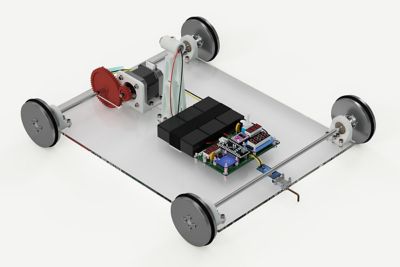

UCL-C’s regional submission

The team’s submission for the regional competition was improved throughout the year, as it iterated through different designs and materials. This is where Ansys simulation came into play. A structural analysis enabled the team to test designs and materials for optimal performance and cost savings. For the IMechE Design Challenge portion of the competition, the team focused on optimizing the chassis, providing accurate vehicular performance, and improving environmental sustainability.

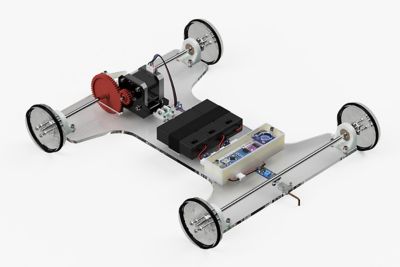

UCL-C’s national submission

The ability to virtually iterate its vehicle in Ansys tools gave UCL-C the upper hand in an otherwise lengthy trial-and-error process. A major part of its final submission was to detail the iterative design process, showing how the design advanced from the regional to the national competition.

Challenging the Boundaries With Simulation

The team first conducted a materials analysis in Ansys Granta EduPack teaching software for materials education. “That’s a software that was introduced to all of us a bit earlier during our courses. It’s extremely useful for material analysis and selection because you can select your desired constraints and filter through a library of many possible materials and manufacturing techniques,” Hassan says.

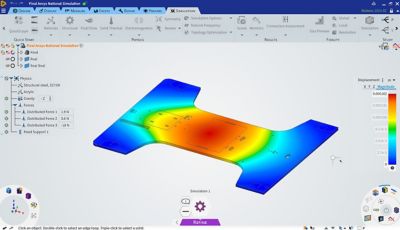

UCL-C used Granta EduPack software to compare the stiffness and cost of plywood, acrylic, and sheet metal, which were three materials the team could supply on its own. Once UCL-C decided on acrylic as the most suitable material due to its high material performance index, as well as its ability to withstand changes in humidity and temperature, the team completed an FEA in Discovery software.

“We created a digital twin of our minimum viable product and used its deflection as our target value when iterating chassis designs,” Kwong says. “Then we’d calculate cost based on real-life product prices.” This was particularly useful for the cost-savings portion of the challenge, in which teams were also competing to provide a cost-efficient product for their pseudo-customers.

Render of UCL-C’s Ansys Simulation Challenge national submission using Ansys Discovery 3D product simulation software

As a result of iterative FEA, the team was able to reduce the weight of its chassis by 40% using a single-layer cutout design, with wheels cut from the same acrylic sheet as the body. Additionally, the ability to test different thicknesses of the acrylic using simulation helped the team determine which thickness best matched its previously set deflection target value.

Ultimately, the team noted that Ansys simulation enabled it to achieve a 25% cost reduction for weight optimization and 30% less material waste, all while maintaining the requested stiffness and accuracy set by the challenge parameters.

What’s Next for the Team?

“One thing that was really valuable that we gained from the competition was access to the Ansys courses and certifications. We’re trying to upskill in Ansys Fluent fluid simulation software, for example, and now I have the opportunity to do that,” says Hassan.

Several team members have expressed interest in the automotive industry, hoping to receive offers from world-renowned automotive companies that they are completing internships with.

“I think these skills from the challenge can go beyond the university level and into the workplace — translating those skills into practical work as well,” says Kwong.

The future is bright for members of UCL-C, and Ansys would like to congratulate the team again on winning the 2024 IMechE Design Challenge and Ansys Simulation Challenge.

Learn more about the 2025 Ansys Simulation Challenge and the next IMechE Design Challenge. See how an Ansys Student Team Partnership can give your team access to free simulation software and learning resources.

Just for you. We have some additional resources you may enjoy.

“One thing that was really valuable that we gained from the competition was access to the Ansys courses and certifications.”

— Daud Hassan, member of Team C, University College London (UCL-C)

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.