-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

August 9, 2022

Finite Elements Shake Up Seismic Research at UCLA

Researchers at UCLA are conducting groundbreaking research funded by the California Energy Commission (CEC) to analyze the seismic risk posed to natural gas pipelines when they intersect with earthquake fault lines — and even when they don’t. The study affects nearly 40 million residents of the state, and that’s just one element of the project.

Historically, civil engineers have used computer-aided design (CAD) or finite element analysis (FEA) modeling in similar research, but Professor Yousef Bozorgnia of the Department of Civil and Environmental Engineering at the University of California, Los Angeles (UCLA) is leading a team of graduate students and post-doctoral fellows to optimize seismic simulation using Ansys’ multiphysics FEA simulation.

In multiphysics simulations, FEA possibilities expand by giving researchers the ability to simulate across engineering disciplines when needed, such as when studying the interaction between structural mechanics and fluid flow, all within a single, unified simulation environment.

Through the Ansys Academic Program, which provides universities with affordable software for use in the classroom and in research, Bozorgnia and his team are integrating Ansys Mechanical for structural analyses while benefitting from the simulation software’s built-in tools for customization and generated scripting.

Further, Ansys introduced the group to the Texas Advanced Computing Center (TACC) at the University of Texas at Austin, which designs and operates some of the world’s most powerful computing resources.

With the support of Ansys and TACC, Bozorgnia and his team are able to perform next-level seismic simulations that require millions of iterations and affect millions of people in a fraction of the time and cost of previous seismic analysis methods.

Finite Element Analysis for Nearly Infinite Elements

While Bozorgnia heads the project for the university’s Samueli School of Engineering, the team’s research is part of a larger operation. The project is funded by the CEC to quantify the seismic risk of natural gas pipelines throughout the state — a massive infrastructure consisting of thousands of miles of pipelines embedded in soil. Added to this, pipeline size varies significantly, with measurements ranging from 8 to 44 inches in diameter and from 0.2 to 1.2 inches in thickness.

Plenty of geometrical and geological variables also contribute to the complexity of the analyses. For starters, if an earthquake causes a rupture along a fault line, what happens to an intersecting gas pipeline? Next, depending on the size and physical characteristics of the specific gas pipeline, how much of it is embedded in soil? Also, at what angle does the pipeline cross the fault — and what kind of fault line is it? It could be a strikesplit fault (like the well-known San Andreas Fault, where two blocks of rock or land slip past each other horizontally). But it could also be a reverse, thrust, or normal fault; each involve vertical shifting, yet in different directions and at distinct angles.

In addition to variables surrounding fault displacement, other scenarios to consider involve landslides and soil liquefication. During a landslide, with a mass of soil headed straight toward a pipeline, what happens to that pipeline? Also, depending on the soil’s physical characteristics, such as texture, structure, and porosity, an earthquake can cause soil to “liquefy,” creating a flow that could also disturb the pipeline.

With all the variables combined, there are more than one million analyses to consider, which requires millions of iterations. To handle this complexity, Bozorgnia and his team use Mechanical to model the gas pipelines and soil with finite elements while using the highperformance computing (HPC) capabilities of TACC to run a significant number of simulations for every scenario. Fortunately, due to the nature of the research, the extra compute power is free. The National Science Foundation supports TACC with any research project related to natural hazards, which enables UCLA to access their computing resources at no cost.

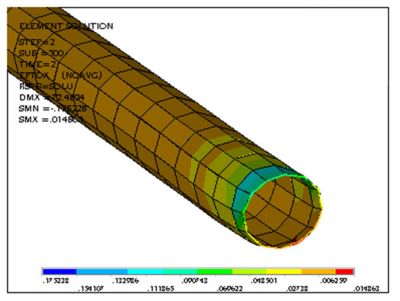

Ansys Mechanical model of the deformation of a 3-km natural gas pipeline subjected to multisupport excitation, simulating the effect of an earthquake for 10 seconds.

“Research funding is always limited,” says Bozorgnia. “We couldn’t do this project if it was not for Ansys and their cooperation, access to the software through the Ansys Academic Program, and interacting with TACC.” Support and funding are crucial for the project, which stretches beyond pipeline and fault line crossing points to include further examination of how pipelines respond during an earthquake, regardless of whether they intersect with the fault line.

Seismic Simulation

Before embarking on the project, Bozorgnia carefully considered which software to use by polling respected members of the research community.

“More than two years ago, we asked which software we should use and the feedback that we received from researchers and practitioners was that Ansys is much easier to use than comparable counterparts,” says Bozorgnia. “Obviously, Ansys’ accuracy and productivity also are important, but for us, to begin with, the short time to learn and use it was the key point that led us to go with Ansys, and we are really happy about it. It has proven to be the right choice.”

Some newer doctoral students on the team had limited prior experience using FEA software. Still, they were able to quickly learn Mechanical with guidance from other team members and additional assistance provided by the Ansys Academic Program, including the Ansys Learning Forum as well as a repository of learning resources online.

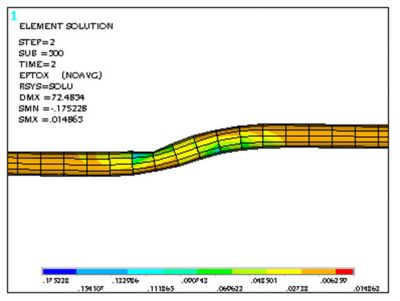

Simulation results in Ansys Mechanical of a 55-inch water transmission pipeline under 6-ft fault displacement with a section-cut view of the deformation at the pipe cross-section.

Along with its ease of use, Bozorgnia’s team finds the solid element selection in Mechanical — particularly elbow elements — to be effective in modeling the nonlinear shape of a pipeline in its entirety. In contrast, some researchers may prepare similar models using shell elements, but that option would only capture the pipeline’s exterior.

With a variety of elements to choose from, the team can model pipelines spanning different lengths and sizes, including thickness. The nonlinear capabilities of Mechanical also enable them to examine the interaction between the pipeline and surrounding soil by placing nonlinear springs along the pipeline in the model.

After creating several pipeline models, the team analyzes and considers all the variables for each by applying a multitude of stresses and strains. Based on the simulation results, they can accurately predict which conditions may cause the pipe to break and when, while observing any other potential damage scenarios likely to happen.

In the traditional way, it would take the team between one to two weeks to script language from scratch to prepare and complete just one model. Today, the team completes a model within 10 to 30 minutes using Mechanical integrated with MATLAB code generation. Likewise, TACC’s supercomputing contributions greatly accelerate the timeline further.

Also, with the software’s remote solve management capabilities, the team is able to perform large-volume calculations and simulations from the UCLA campus, which is nearly 1,400 miles away from TACC’s HPC resources in Austin, Texas.

Bozorgnia says this allows the team to conduct research on-site while benefitting from multiple computers, which together provide thousands of central processing unit (CPU) cores.

High-Powered, Far Reaching Projects

By the end of 2023, Bozorgnia expects to have the final stage of the project completed, which is an interactive database of natural gas pipeline and earthquake fault line locations. With all of the team’s findings and pipeline combinations cataloged, interested parties will be able to enter a pipeline location and discover the nearest fault line and risk.

As the team compiles their natural gas pipeline research, they’re also working on another massive undertaking — examining the seismic risk to water transmission pipelines that run in southern California. Akin to the first project, Bozorgnia leads the group to analyze water transmission pipelines and crossing earthquake faults. Though the properties and contents of water transmission pipelines differ from natural gas pipelines, the team employs the same technology, simulation, and finite elements to model and analyze all the variables. The group is also creating a separate interactive database for this research, which is slated for completion by mid-to-late 2023.

Simulation results in Ansys Mechanical of a 55-inch water transmission pipeline under 6-feet fault displacement illustrating the deformation of the pipe cross-section (left) and the strain distribution along the pipeline near the earthquake fault zone (right).

When entering a pipeline location in the natural gas pipeline database, the software will present a probability of failure based on the variable cases within the database, including proximity to fault lines.

Similarly, in the water transmission database, entering a location will show nearby major transmission pipelines that intersect with fault lines, colored in red, yellow, or green depending on closeness and risk.

Both databases are expected to have a substantial reach. The team anticipates that both platforms will be used by individuals and state agencies such as the CEC as well as utility companies that use natural gas or water.

“The agencies and companies can enhance their facilities for seismic issues and, consequently, the residents of California will have less risk in relation to water and natural gas,” says Bozorgnia. “The beneficiaries of the whole project are going to be the millions of people living in California, especially in southern California, with about 13 million residents.”

Positive Aftershocks

Bozorgnia’s team will share the team’s research and results in journal papers within the industry. However, neither milestone will mark the end of the team’s exploration with pipelines, fault lines, or simulation.

“That’s a part of academic research: If there is a feature we haven’t used and we want to solve a complicated, complex problem, we always have to try new things,” says Bozorgnia. “The problem we are solving is a very real problem, so we will always try new simulation software and technology, finding new ways to analyze our data. Ansys has helped us significantly to solve Simulation results in Ansys Mechanical of a 55-inch complex real-world infrastructure problems.