Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

“Thanks to PyAnsys we were able to freely combine modules in a common Python environment without specialized knowledge, allowing us to create a shape-evolving performance optimization development flow that takes into account new technology (NT) maps, with 100 times greater efficiency.”

— Tomonori Yamada, President and Representative Director, Company/Yamada Unit Power Company, Ltd.

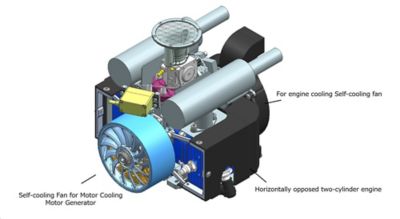

Yamada Power Unit Co., Ltd. designs, develops, and manufactures a wide range of motor inverters for electric automotive and aircraft applications optimized to customer requirements. Specifically, the startup has experience developing hybrid unmanned aerial vehicles that use engines and gas turbines. To satisfy market expectations, Yamada Power Unit must develop these extremely high-performance solutions subject to tight time constraints and budgets.

Challenges

Yamada Power Unit customers demand compact, lightweight, and high-power density designs, which entails optimization in specific conditions with many trade-offs across multiple fields. However, due to high initial manufacturing costs, only one or two prototypes are possible.

A front-loading approach involving robust planning and design early in the lifecycle — when design accuracy is enhanced, and design freedom is high — ensures that the costs associated with any design changes remain low, while still maintaining overall product quality. Choosing software that allows for feedback during the development phase through front-loading is important to facilitating the rapid and successful introduction of high-quality products to the market. Multiphysics capabilities and ease of parametric analysis via API were the main criterion for software selection.

Engineering Solution

In typical parametric model optimization, analyzing many parameters often restricts the study to specific operational points or requires simplifying the mesh due to immense computational complexity. However, Evolutionary Algorithm (EA) model optimization allows for efficient shape searches through cross-fertilization and natural selection techniques.

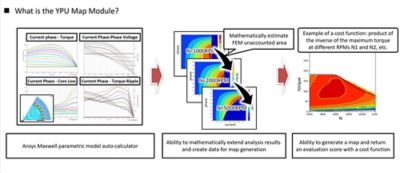

Ansys open source PyAEDT scripting interface facilitates the seamless execution of various operations in a standard Python environment, as opposed to relying on IronPython environment. This capability enabled Yamada Power Unit to extract results from parametric analyses, and to generate performance maps for global control and external optimization algorithms.

Yamada Power Unit developed software specifically for these tasks. The outputs are presented as graphical maps and flowcharts, which illustrate the optimization of speed and torque characteristics on the NT map. The extraction is required with superior torque characteristics. The NT map was produced using PyAEDT scripts, integrating all of Yamada Power Unit’s inhouse tools and requiring less manual operation and fewer computations than previous methods. Subsequently, optimization was conducted using an algorithm that accounted for generational evolution based on map feature scores.

Once the desired target values were reached, the team automatically moved on to Ansys Fleunt to perform thermal feasibility studies and other processes. Both Fluent and Ansys Mechanical were used for paralympic analysis to determine the thermally or structurally feasible geometry for the model obtained from the optimization.

Finally, to unlock results of various motor analyses in Ansys Maxwell required the creation of a parametric model that could be used in large-scale high-performance computing (HPC) environments. With the help of 10 HP workstations (48 cores per workstation) working in parallel, it was possible to create a parametric model of Ansys Maxwell with the best shape in the shortest amount of time.

Benefits

- Parametrized motor model geometry with the help of simulation to enable parametric analysis of geometries individually in a high performance computing (HPC) environment

- Improved development efficiency 100x using simulation-driven parametric analysis, increasing the number of geometry inspections from several to several hundred geometries per day to quickly identify the best inverter design per customer application

- Modeling in a simulation environment significantly reduced the number of physical prototypes while simultaneously improving inverter geometry to increase overall electric motor efficiency, including energy output and range

- PyAnsys enabled very smooth program manipulation of Ansys software overall. Using PyAnsys scripts, it was possible to perform various operations in Fluent, Mechanical and Maxwell to better understand mechanical and thermal motor characterisitics

- Introducing the PyAnsys scripting interface helped the team, without previous experience using the software, to freely combine modules in Python to create a shape-evolving performance optimization flow

- The resulting workflow considers company's new technology (NT) maps to further understand the ramifications of introducing a new technology into it

Erfahren Sie, wie Ansys Ihnen helfen kann

Erfahren Sie, wie Ansys Ihnen helfen kann

Kontakt

Danke für die Kontaktaufnahme

Wir sind hier, um Ihre Fragen zu beantworten und freuen uns auf das Gespräch mit Ihnen. Ein*e Mitarbeiter*in unseres Ansys-Verkaufsteams wird sich in Kürze mit Ihnen in Verbindung setzen.