Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

“As part of sensor development, I created an alignment method for the projector that linearizes focus (Opt. Eng. 61(11), 2022). The method worked great, but I was concerned that experimental iteration would not necessarily guarantee that I was using the optimum input variable settings unless a substantial amount of time was invested. Thus, I decided to simulate the full range of potential variables using Zemax to provide the ray tracing and Matlab to manage the data flow and graph the results. With this trade space analysis, I was able to determine the variable settings that maximized depth of field and minimized focus position error (Opt. Eng. 62(2), 2022). I have since applied the simulation approach to a new sensor and determined the variable settings before the sensor was even built.”

— Matthew Jungwirth, SPIE Fellow, Nordson TEST & INSPECTION

CyberOptics is a leading global developer and manufacturer of high-precision 3D sensing technology solutions. The CyberOptics portfolio of industry-leading, high-precision inspection and metrology sensors and systems, is now part of Nordson Corporation's TEST & INSPECTION divisions. Nordson TEST & INSPECTION used the Ansys Zemax DDE server to simulate optical performance from Matlab. As part of sensor development, Nordson TEST & INSPECTION created an alignment method for the projector that linearizes focus (Opt. Eng. 61(11), 2022).

The method worked great, but they weren’t done yet.

Challenges

- Concerned that experimental iteration would not guarantee that they were using the optimum input variable settings unless a substantial amount of time was invested.

- Design time versus tolerancing time was about 50/50.

Engineering Solutions

Ansys Zemax OpticStudio is widely used in optics and photonics to design and optimize optical systems, such as lenses, mirrors, and other optical components.

By utilizing high-yield optimization techniques in OpticStudio, optical designers can create designs that are robust against manufacturing variations, leading to higher production yields of optical components and systems that meet performance specifications. This is especially crucial in industries like precision optics and photonics, where the tolerances are often tight, and high yield is essential to cost-effective production.

Nordson TEST & INSPECTION decided to simulate the full range of potential variables using Zemax to provide the ray tracing and Matlab to manage the data flow and graph the results. With this trade space analysis, Nordson TEST & INSPECTION determined the variable settings that maximized depth of field and minimized focus position error (Opt. Eng. 62(2), 2022). They have since applied the simulation approach to a new sensor and determined the variable settings before the sensor was even built.

Figure 1. The SLI system under test. The single projector/camera combination examined is labeled.

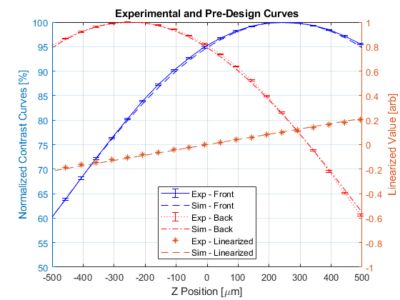

Figure 2. Comparison of experimental and simulation results. Labels – ‘Exp’ = experimental curve, ‘Sim’ simulation curve, and the error bars are normalized contrast values of ±2σ from four experimental trials.

Benefits

- By incorporating high-yield optimization into their design process, tolerancing time has been cut down and the total split is now about 75/25.

- Nordson TEST & INSPECTION estimates that the simulation method saved about a week of their time, and it will save another week for each new sensor.

- OpticStudio is used throughout the organization as the optical scientists have been trained on Zemax.

Figure 3. Results from the simulated trade space analysis for linearized slopes.

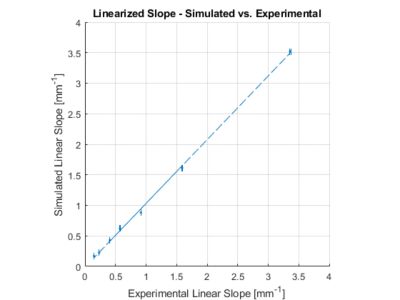

Figure 4. Comparison of simulated and experimental results for linearized slope. The error bars are experimental slopes of ±2σ from four experimental trials.

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.