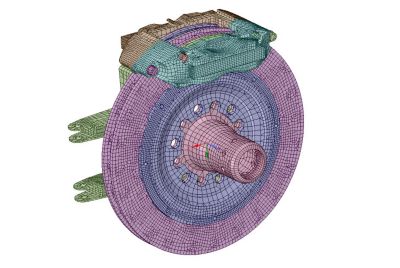

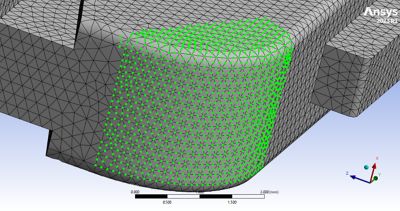

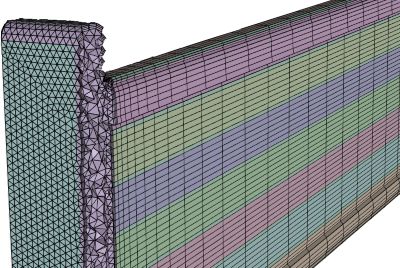

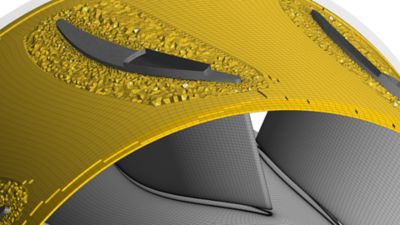

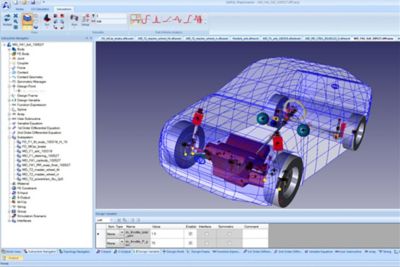

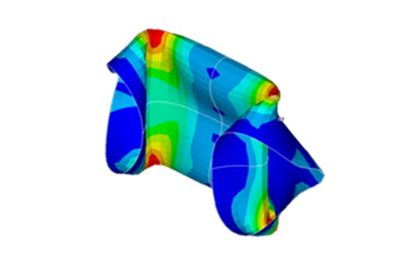

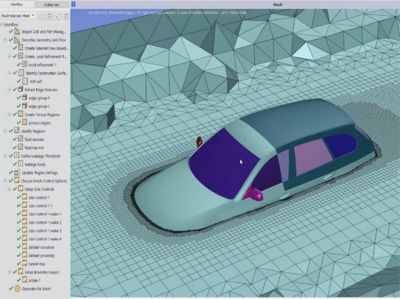

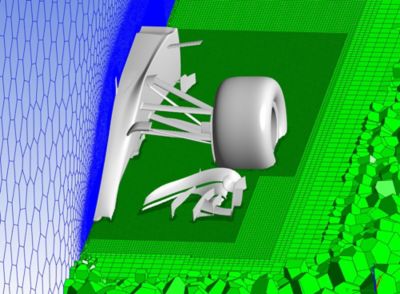

Ansys meshing capabilities help reduce the amount of time and effort spent to get to accurate results. Since meshing typically consumes a significant portion of the time it takes to get simulation results, Ansys helps by making better and more automated meshing tools.

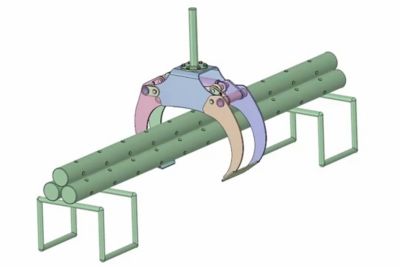

Whether performing a structural, fluid or electromagnetic simulation, we can provide you with the most appropriate mesh for accurate and efficient solutions. We offer easy-to-use, automated meshing tools, including tools that enable you to hand craft your own mesh. Smart defaults are built into all tools to make meshing a painless and intuitive task and deliver the resolution required for your problem.