-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

PRESS RELEASE

DATE: 04/06/2021

ESSS and Ansys Significantly Boost Product Quality with Powerful Particle Modeling Workflow

Ansys’ next-gen high-fidelity simulation solution speeds product design by 20-90x

Key Highlights

- ESSS and Ansys are delivering a discrete element modeling (DEM) workflow to overcome particle movement design issues for many industrial applications

- The new tool enables customers to simulate product performance across thousands of real-world operating scenarios

PITTSBURGH, PA, April 6, 2021 – ESSS and Ansys (NASDAQ: ANSS) are collaborating to provide an improved discrete element modeling (DEM) workflow for quickly analyzing and assessing particle movement across numerous industrial applications. Interoperable with industry-leading Ansys flagship solvers, the workflow helps engineers design highly reliable products, slash development time and win the race to market.

From candy to vacuum cleaners, nearly 70% of industrial products experience bulk granular material flows, where different-sized particles with complex shapes interact, potentially impacting a product’s efficiency or structural integrity. To overcome this difficult design challenge, engineers require DEM, coupled with structural and fluid analysis, to assess the flow behavior of these granular particles early in the design phase.

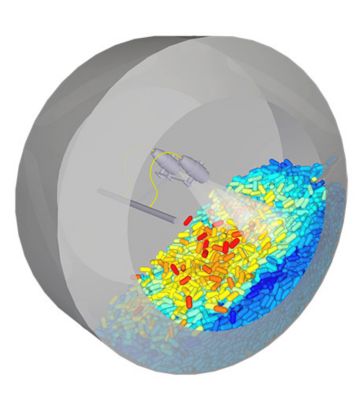

Ensuring product quality of pharmaceutical tablet coating process using Ansys CFD and Ansys Rocky

ESSS and Ansys’ new workflow, Ansys Rocky, is a robust 3D DEM solution for tackling particle movement design issues. Harnessing multiple GPUs simultaneously to analyze bulk material flow systems 20-90x faster, Ansys Rocky runs high-fidelity, uncompromised massive particle models. Seamlessly integrated with Ansys® Fluent® and Ansys® Mechanical™, Ansys Rocky swiftly simulates fully coupled fluid and structural systems’ bulk material movement and reaction to forces such as gravity and adhesion, ensuring new products are more reliable than ever.

“We welcome the news of the agreement between Ansys and ESSS. As you can imagine, most products we design and manufacture involve particulate systems and are inherently multi-components and multiphysics,” said Lei Zhao, R&D director at PepsiCo. “R&D and engineering teams at PepsiCo rely on Ansys Fluent to perform computational fluid dynamic analysis and Ansys Rocky to perform particle dynamic analysis to ensure product quality and optimize manufacturing processes. The results are a shorter product development cycle with less waste and more efficient processes that help meet the growing demand for healthier and more environmentally friendly products.”

Optimizing packaging of potato chips using Ansys Rocky

Unlike a traditional DEM code, Ansys Rocky accurately models particles shapes including arbitrary 3D shapes, 2D shells and flexible fiber, helping engineers quickly solve challenging design problems with very complex geometric design variations.

“The ability to model large number of particles with real shapes, ranging from a pharmaceutical tablet to potato chips, has expanded Rocky’s reach from traditional sectors, like heavy machinery, to new areas such as agriculture, battery design and additive manufacturing,” said Clovis Maliska, Jr., CEO at ESSS. “Additionally, Rocky’s integration into Ansys’ workflow extends the power of DEM analysis beyond design centers and brings simulation into manufacturing, operation and production, enabling companies to optimize the production, transportation and packaging material handling of bulk and discrete particle systems.”

Ansys Rocky delivers unique usability, portability, solver performance and multi-GPU acceleration to cost-effectively calculate particle transport.

“Ansys Rocky incorporates the latest technology advances in customization and user experience integration to augment fluid and structural mechanics with particle mechanics, enabling customers to understand how their products will perform across thousands of real-world operating scenarios,” said Shane Emswiler, senior vice president at Ansys. “From modeling complex shapes to flexible fibers, Ansys Rocky combines its multi-GPU capabilities with Ansys’ flagship simulations — empowering our customers to rapidly run large, highly realistic simulations that include key bulk material details.”

About Ansys

If you've ever seen a rocket launch, flown on an airplane, driven a car, used a computer, touched a mobile device, crossed a bridge or put on wearable technology, chances are you've used a product where Ansys software played a critical role in its creation. Ansys is the global leader in engineering simulation. Through our strategy of Pervasive Engineering Simulation, we help the world's most innovative companies deliver radically better products to their customers. By offering the best and broadest portfolio of engineering simulation software, we help them solve the most complex design challenges and create products limited only by imagination. Founded in 1970, Ansys is headquartered south of Pittsburgh, Pennsylvania, U.S.A. Visit www.ansys.com for more information.

Ansys and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

About ESSS

Engineering Simulation and Scientific Software (ESSS) is an innovative international provider of engineering simulation products and services operating in more than 10 countries. With over twenty-five years of experience, and over 200 employees, ESSS is a well-established Ansys channel partner. In addition, ESSS develops new simulation tools, runs ESSS Institute and drives broader adoption of customized CAE solutions in the energy industry. Visit https://www.esss.co or https://rocky.esss.co for more information.

ANSS-T

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.