-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

August 18, 2021

Shedding Light on a Shadowy Target

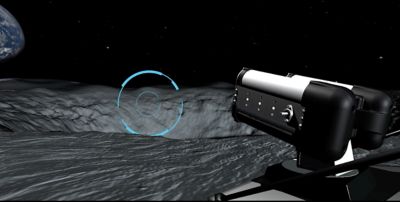

VELOS system launching into a permanently shadowed region in VR environment

Could something as small and lightweight as a softball enable extended lunar missions and make the moon a launch pad for interplanetary travel?

A multidisciplinary team of 20 undergrads and graduate students from Arizona State University’s (ASU's) Luminosity Lab hopes the configurable, multi-probe exploratory system they call VELOS may provide a giant leap in that direction.

VELOS – which is short for Variable Exploratory Lunar Observations System — was one of eight finalists in NASA’s 2020 Breakthrough, Innovative and Game-changing (BIG) Idea Challenge. The annual competition encourages university teams to propose new approaches and technologies in support of the space agency’s Artemis program, whose mission is to return humans to the moon by 2024. The most promising proposals — the finalists — receive grants to bring their ideas to life.

For the 2020 challenge, students developed technology systems to explore one of coldest and darkest places in our solar system: the largely uncharted permanently shadowed regions (PSRs) of the moon. Little is known about the area in and around the PSRs, making data collection of utmost importance.

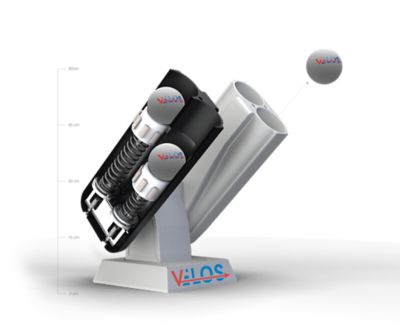

Launcher subsystem

Probe subsystem

VELOS, which received the 2020 Innovation Award, provides a means for data collection in a combination launcher/probe system. Its catapult-like launcher assembly is capable of lofting four softball-sized, sensor-filled probes 100 meters (109 yards, roughly the length of a football field) on a preset trajectory into and around the PSRs. VELOS integrates with any Commercial Landing Payload Services (CLPS) lander, the payload delivery service to the moon.

VELOS’ probes can accommodate any sensor that fits, meaning the system could eventually be used for a number of science missions. However, for project purposes, the ASU team focused on a specific goal: understanding which elements are present in the regolith, which is the unconsolidated rocky material inside PSRs. That includes detecting ice that could provide a water source for sustained lunar operations and even human habitation.

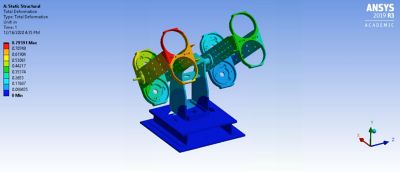

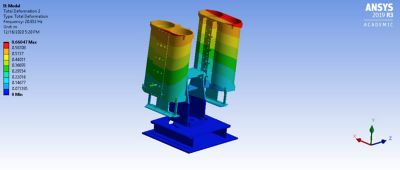

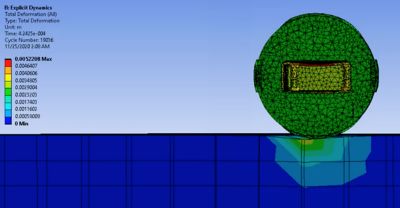

The ASU team used Ansys Explicit technology, part of the Ansys Mechanical suite, to validate VELOS’ moon-readiness, including structural load testing, vibrations testing and drop testing Ansys Workbench’s transient thermal analysis capabilities provided insight into how long the probes could reliably perform in the PSRs’ ultra-cold environment.

Results of the launcher static structural simulation

Simulating the Future on Ice

PSRs are located in craters at the moon’s north and south polar regions, areas never exposed to direct sunlight. Temperatures there can be as low as 35 Kelvin (-394° F). That is colder than Pluto, which averages a slightly less frigid 45 Kelvin (-378° F). Both make the lowest temperature ever recorded on Earth — 184 Kelvin or -128° F — seem like a sauna.

As forbidding as PSRs are, though, it appears likely they have one attribute essential to future deep-space missions: ice.

And where there’s ice, there’s typically water.

Water stored as ice on the otherwise bone-dry moon could be revolutionary for science, space exploration and mankind itself. A source of water on the moon could sustain human life and supply hydrogen and oxygen, the building blocks of rocket fuel. That could provide a ready energy reserve for spacecraft going back and forth between the moon and Earth, as well as for those journeying to Mars.

The challenge, of course, is creating PSR exploration technology that can withstand harsh lunar conditions, not to mention the rigors of deep space travel.

That’s a tough assignment under the best of circumstances. For ASU, doing the work on a compressed schedule — and during a global pandemic that shuttered many test facilities — made simulation even more important than normal.

From the time they received the challenge grant in February 2020, the ASU student team had less than a year to design, conduct proof-of-concept testing and validate VELOS, plus prepare a presentation for NASA. Meeting the timeline would have been impossible without rapid design iteration. And that was possible only by relying heavily on fast, accessible simulation.

Simulating Shock, Impact and Brutal Cold

The primary function of the VELOS probe is to collect data and transmit it to the launcher. But none of that is possible if its probes can’t survive the shock of being launched, the impact of landing or the area’s extreme thermal environment.

With the support of advisors including ASU’s Jim Bell, the primary investigator on the Mars rover science camera, and help from Ansys channel partner PADT, the team simulated turret structural integrity, probe drop testing and thermal response to PSR conditions with Ansys software.

Results of the launcher shock and vibration simulation

VELOS uses preloaded springs mounted to a rotating turret to launch the probes in an array that maximizes data collection potential. Once the CLPS lander’s camera identifies a PSR, the turret swivels toward it then launches the four probes sequentially. The team performed structural and vibration analysis of the turret to help them understand the load placed on it during probe launching. This enabled a design that could withstand those forces while also ensuring that launching wouldn’t disturb the lander’s sensitive equipment.

When it came to designing the probe’s exterior, protecting the important electronics inside it was key. The probe’s outer shell, which is made of aluminum and covered in an insulated blanket, and the internal energy absorption material — an aerospace-grade carbon foam —were designed to plastically deform during impact yet still protect the sensor electronics. To test the efficacy of their design, ASU chose a drop test velocity that represented a worst-case scenario: the probe impacting the regolith at 12.72 m/s without any angle of incidence.

The first simulation compared dropping the probe from a height of 1.67 meters (5.4 feet) onto a concrete surface and a sand-based surface. The resulting accelerations were used to run a structural analysis of how the probe shell would behave if it was launched onto a solid surface. The simulation indicated the probe shell’s performance was consistent with the design intent. It yielded and sustained damaged at the point of maximum stress while providing rigid protection for the electronics inside.

Results of the probe thermal simulation

Determining the lifespan of the probe’s electronics at 35 Kelvin could have been done in a facility — if one had been readily available and not cost-prohibitive.

Instead, the ASU team performed partial vacuum testing using liquid nitrogen for cooling then validated the physical model, which assumed an initial probe temperature of 36 C (96.8 F) and an ambient temperature of -237.85 C (-396.13 F), in a transient thermal simulation using Ansys Thermal. The team determined that the probe’s electronics should be able to operate continuously for five hours before temperature control is lost and the probe stops functioning.

A Novel, Scalable Approach

VELOS physical prototypes proved that it is more than just a wishful concept. During testing, the launcher successfully actuated, sending the probe more than 16.5 meters (54 feet) in Earth gravity, which is the same as the desired 100 meters in lunar gravity. The team also conducted longer duration thermal/vacuum (TVAC) testing.

What’s next for VELOS? The ASU Luminosity Lab team is applying for follow-up funding through NASA Tech Flights Opportunity, which provides access to test flights and other NASA programs.

In the meantime, the group — which is accustomed to creating novel solutions to address some of the world’s most pressing challenges — has developed an innovative, low-cost, reliable and scalable approach for exploring an unknown environment. That’s something they would have been unable to do without Ansys simulation.

And who knows? Someday, the team’s system might help scientists find water in the deep, dark crevices of the moon, allowing astronauts who travel there in 2024 and beyond to become long-term visitors.