-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

June 19, 2023

Simulating Another Victory: Reigning Formula Student Champs Develop Their First Electric Race Car

Every year, hundreds of students compete in the annual Formula Student race car competition at the famed Silverstone Circuit in England. Challenged to build a winning single-seat race car, teams design and develop their car for about 10 months leading up to the main race.

Last year, UGRacing from the University of Glasgow in Scotland reigned as champions, and this year they’re increasing the stakes by designing their first-ever electric vehicle (EV) — making a consecutive win significantly more difficult.

To navigate the new set of challenges involved in EV design, the team is using Ansys’ multiphysics simulation to analyze thermal, fluid, and mechanical dynamics throughout the car and its battery. With access to the tools through an Ansys Student Team Partnership, UGRacing is strategizing another win this summer with simulation in the front seat.

UGRacing, a student team from the University of Glasgow, competes in a preliminary acceleration run during last year’s Formula Student competition.

An Electric Drive for Success

This year’s Formula Student competition marks its 25th anniversary, and the event will take place July 19-23. The Institute of Mechanical Engineers has managed the competition since 1998, but students come from a variety of academic backgrounds. UGRacing comprises nearly 200 members from undergraduate- to doctorate-level programs, including engineering, teaching, law, design, and many others.

Each year, students must design a car from scratch and cannot use a previous year’s model, though most teams refer to previous designs for insight. However, by attempting a new type of car, that’s not an option for UGRacing this time around.

Members of the UGRacing team help develop the team’s first electric vehicle (EV) race car, the UGR23.

“Every year, regardless of internal combustion engine (ICE) cars or EVs, you have to start from scratch and bring a new design and chassis,” says Luke Waugh, head of the Accumulator team at UGRacing. “But typically every year, you will improve from the previous year’s design. The switch from ICE to EV is monumental because there’s no previous car to look to and improve from; we have to make the first one.”

Waugh oversees the accumulator design for the team’s latest EV model. An accumulator is another term for a high-voltage battery, and for an EV, the battery is crucial to the car’s performance.

Fellow teammate Lukasz Poloczek, a thermal management engineer at UGRacing, makes sure the accumulator stays cool by using Ansys Fluent to perform computational fluid dynamics (CFD) analyses. Fluent enables him to study air flow throughout the vehicle and to the accumulator. With this insight, Poloczek determines how many fans are needed and in which direction air must flow to maintain ideal battery temperature.

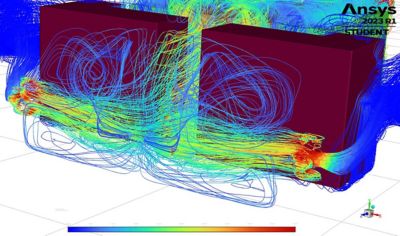

Ansys Fluent simulation illustrates the airflow around the accumulator. This angle shows the front of the accumulator, with two blocks representing where the batteries will be placed and the colors depicting flow velocity.

“Ansys Fluent has been monumental in helping us understand the power cooling, because otherwise we would just be going in blindly without being able to understand what improvements we need to make and whether the cooling is equal,” he says. “For example, you might have certain spots that heat up too much, which would kill the whole model. Fluent has been incredible because I can run the full simulation, and we can look at the airflow throughout the vehicle.”

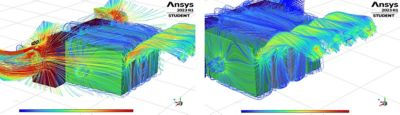

UGRacing team members analyze the airflow surrounding the accumulator at different angles in Ansys Fluent. These simulations show the side of the accumulator.

UGRacing is designing a 400-V accumulator that will output direct current (DC) voltage to an inverter, which will switch DC voltage to three-phase alternating current (AC) voltage. Three-phase power distribution provides a consistent flow of power that is more efficient than a single-phase circuit, requiring less material and mass.

Poloczek also uses Ansys SpaceClaim 3D modeling software to set up geometries for the Fluent simulations, while the team’s structural lead uses finite element analysis (FEA) in Ansys Mechanical to design the chassis. By simulating forces onto different parts of the chassis, the structural team can predict how it will react to various forces on the track.

While winning competitions is desirable, this hands-on, practical experience is what the team is truly all about.

“The reason this team exists at the end of the day is to teach students practical skills that they otherwise wouldn’t get in their classes, and to provide hands-on experience that’s going to help them down the line,” says Cisa Muir, head of Operations of UGRacing. “They’re going to be able to go to an employer and already have years of experience that people in industry may not even have. Being able to use Ansys simulation tools through the Ansys Academic Program gives the students, and the team as a whole, so much of an extra step forward.”

Cruising Over Speed Bumps with Simulation

Without a previous EV design to review, the team relies more heavily on the predictive insights of simulation. Instead of using simulation as a post-analysis tool or for verification after design, the team is using simulation throughout design and has found significant value in the new approach.

“One of the biggest challenges we’ve had is putting things together and only realizing there’s something wrong after we’ve built it. Using Ansys simulation gives us instant, ongoing response results to how our current design is being set up, and it allows us to implement those changes in an ongoing process for the design instead of when we’re on the track,” says Waugh. “Having the simulation at the beginning allows us to change the designs early on, rather than realizing there’s a problem way too far down the line.”

Members of the UGRacing team at the 2022 Formula Student competition complete scrutineering rounds before the main race.

The team usually starts designing the car in September, aiming to have its first rendering completed by early January to allow enough time for manufacturing. During this process, the team can see their design materialize and determine what they want to adjust, including its size. Currently, this year’s model — the UGR23 — is about 2.8 m long and 1.4 m wide, but the final design can change before it hits the track. Surprisingly, teams assemble their cars at the main event.

“You have to pass scrutineering, which is typically about two or three days for teams to adjust their cars and set up in the garages to build their cars and prepare with their best foot forward,” he says. “A lot of teams come a long way, and you can’t just have the whole car assembled and send it along. We always have to build it at the track again.”

The Formula Student competition takes place across five days, including rounds for static and dynamic challenges as follows:

Static | Dynamic |

|

|

UGRacing performs a tilt test during the 2022 Formula Student competition.

The main race, which is considered the endurance portion of the dynamic events, consists of 22 laps at 1 kilometer each. Sixty teams raced last year, but only 20 used EV cars — and out of that minority, only six passed scrutineering, which puts UGRacing’s upcoming challenge into perspective. This year, 100 teams are expected to race, though the ratio of ICE to EV is not yet disclosed.

As mentioned, one of the most crucial components of an EV is battery performance. Using simulation and UGR23’s approximate car parameters, the team estimates that their car will require 7.5 kilowatt hours of battery power to cross the finish line.

Fluent’s thermal modeling capabilities are helping the team reach this goal by finding an ideal balance in battery temperature to increase performance.

“If the battery gets too hot, it will shut down, which would instantly cut off all performance,” says Waugh. “But at the same time, the more heat you can reject from the system, the higher current you can run, which correlates to a higher power.”

The UGRacing student team wins the 2022 Formula Student competition.

Winning Tools for a Winning Team

Muir says some of the most rewarding moments for the team came after their 2022 victory.

“We are the most successful team in Scottish history, which is something we’re very proud of,” she says. “We love to represent Glasgow and Scotland as a whole, and it was really exciting this year to see the whole country, including every sort of Scottish team, start to support us after we won the competition last year.”

Ansys is dedicated to ensuring the affordability and accessibility of simulation tools and promoting science, technology, engineering, and math (STEM) education to equip tomorrow’s engineers.

“The fact that we have access to these amazing products without cost is a game changer,” she adds. “Unfortunately, we would struggle to afford it without the help and generosity of Ansys, and our team wouldn’t exist without the help of our partners like Ansys.”

To learn more, visit Ansys Academic for program information and resources for Student Design Teams.