-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

February 24, 2023

Turning Recycling Waste Into Automotive Components Using Simulation

Plastics are everywhere, including places we would rather not see them — like our oceans. According to National Geographic, “Every year, about 8 million tons of plastic waste escapes into the oceans from coastal nations. That’s the equivalent of setting five garbage bags full of trash on every foot of coastline around the world.”1

Recycling is an obvious solution, but most of us have a naïve understanding of recycling. You may think that plastics, for instance, arrive at a recycling center ready to be melted down and formed into new raw materials, which can then be used to make new plastic components. In reality, there is a lot of sorting and chopping involved to make the plastic pieces small enough to flow in a mixer, and there are chemical additives used as binders or flow enablers to enhance the properties of the resulting material.

Even after all of that, a recycler can’t be sure the recycled plastics will be useful to potential customers seeking to turn the plastics into new products. Aesthetically, the recycled version will probably not look good enough to be used on the exterior of a product, so it’s typically placed out of view, like behind a car bumper or sandwiched between two pieces of metal. The recycled plastic may not have the same strength as the equivalent virgin plastic material, and the strength will vary from batch to batch. This is because the recyclable materials in any municipal waste stream vary depending on what’s being thrown away at any given time, and hence are typically a blend of similar plastics.

So, how can recyclers and their customers determine and keep track of the physical properties of recycled plastics and effectively deal with the inherent variability of these properties? The answer lies in a process that combines four Ansys technologies in one streamlined workflow.

The Plastic Recycling in Stochastic Modeling (PRISM) Project

To make it easier for recyclers and their customers to produce viable recycled plastics and use them in products, Ansys collaborated with three companies in the United Kingdom — Impact Recycling, Impact Solutions, and Far-UK — in the Plastic Recycling in Stochastic Modeling (PRISM) Project. Stochastic refers to randomness, and it’s in understanding the randomness of the feedstock and the resulting physical properties of the recycled plastic that simulation can be of great value.

Impact Recycling, which offers a sustainable solution for recycling post-consumer products, can successfully recycle upwards of 80% of the plastic municipal waste they handle. However, that still leaves an expensive 20% on which they must pay taxes to send to landfills or incinerators. Companies like Far-UK, which produces automotive parts for niche vehicles, could potentially save a lot of money in manufacturing while offering a more sustainable product by using recycled materials from companies like Impact Recycling, provided it meets the exacting properties of the original equipment manufacturers (OEMs) to which they sell. Part of the challenge is presenting this as an alternative to the virgin polymers automotive OEMs have been using for decades.

“These companies need to understand when they have to use virgin materials and when they can use a recycled material instead," says Donna Dykeman, R&D Manager for Collaborative R&D at Ansys. “And that's where Ansys simulation solutions come in.”

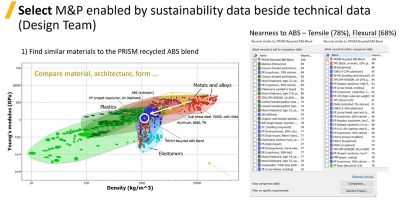

Positioning the new PRISM recycled ABS thermoplastic blend with other material.

A Simulation Pathway to Better Recycling

Working together, Impact Recycling, Impact Solutions, Far-UK, and Ansys achieved the following successes through the PRISM project:

- A novel recycling process resulting in the commercialization of municipal waste streams for plastics, challenging the need for virgin-grade materials.

- A simulation-led workflow to test the optimal use of a material with highly variable material properties in design.

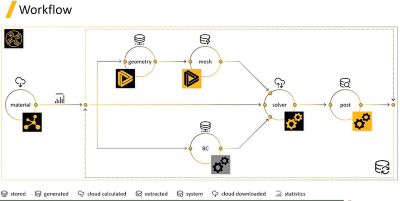

This simulation workflow consisted of a combination of four software components: Ansys Granta MI, Ansys SpaceClaim, Ansys optiSLang, and Ansys LS-DYNA. Together, these simulation tools were used to optimize workflows to handle the uncertainty of material properties and screen geometries for applications to replace virgin materials with recycled ones.

A simulation-led workflow developed to test the optimal use of a material with highly variable material properties.

“Granta MI stores the materials data,” Dykeman explains. “Then, LS-DYNA was used to create the material card based on test data. The card was validated against test coupon geometries and subcomponent geometries (e.g., a beam under various loading conditions). This first step of testing and material card generation was performed by Far-UK. Next, we used optiSLang to create a workflow with SpaceClaim and LS-DYNA to vary the geometry of candidate parts and the material properties until an optimal design was reached. When an OEM specifies a property or geometry tolerance that must be met, the outcome of the optimization process suggests which property requires improvement, and by how much.”

PRISM Case Study

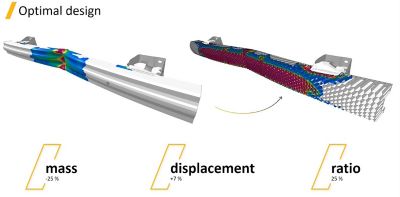

Ansys used this workflow to design a plastic honeycomb made of recycled materials to be installed behind the surface of a car bumper to absorb the shock of a crash. After proposing an initial geometry for the honeycomb, engineers performed LS-DYNA crash testing to see how well the structure absorbed and dispersed the energy of the crash.

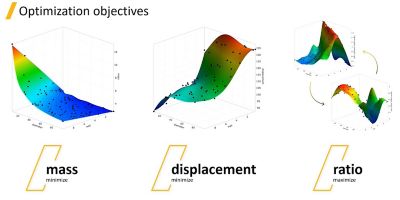

Ansys optiSLang was used to find the optimal design by minimizing mass and displacement while maximizing the accumulated energy of the honeycomb.

Through a parametric study involving an iterative series of simulations, Ansys determined the optimal geometry of the bumper — such as the type of honeycomb structure, how thick the cells should be, bumper dimensions, and where mass could be removed from the benchmark steel bumper to achieve the allowable displacement before contact with more trunk components.

“Ansys optiSLang is able to help designers find where the sweet spot of a design is through automation,” Dykeman says, “by running hundreds to thousands of simulations until it converges on an optimal design.”

The optimal design using the PRISM honeycomb structure.

PRISM Results

Impact Recycling was able to:

- Reduce costs for manufacturing recycled material

- Increase the rate of production from 400 to 700 tonnes per year

- Produce a new recycled plastic stream that addressed the high demand versus supply of recycled plastics in light of the plastic tax on consumer packaging (virgin plastic costs 30% more, driving the demand for recycled polyolefins)

- Promote their new recycled ABS thermoplastic stream to a wider application audience, such as automotive

- Reduce their CO2 footprint, with emissions 9X less than when using virgin feedstock

Far-UK, as a producer of automotive parts, benefited from the chance to explore how to manage the variability of materials from recyclate in design with the aim of introducing materials with lower costs and carbon footprint in the future. It also used Ansys simulation tools to generate and validate the material card for use across wider applications.

For Ansys, the PRISM project showcases how material circularity and smart eco design can be achieved by applying the right solvers connected with a simulation digital thread. Connecting the material data, processes, and tools used into a holistic workflow allowed the challenge of the highly variable material property to be overcome to find the right design and application. This is a step in the right direction for a more sustainable future.

For more information on the PRSIM Project, check out the biweekly webinar Ansys Connect Series to hear about it from company representatives.

References

- “The world’s plastic pollution crisis explained.” National Geographic, June 7, 2019.