-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

Data is essential to artificial intelligence (AI). It’s used to train, maintain, and validate AI models. Consequently, as AI becomes more prevalent across industries around the world, the need for greater data storage is rapidly increasing. It’s projected that about 181 zettabytes (ZB) of data will be generated in 2025, with forecasts ranging between 175ZB and 200ZB. To put that into perspective, 1ZB is equal to 1,000 exabytes (EB), 1 billion terabytes (TB), or 1 trillion gigabytes (GB). That’s a lot of data. In fact, it’s far more data than we can store. Global data storage capacity is expected to reach only about 16ZB next year.

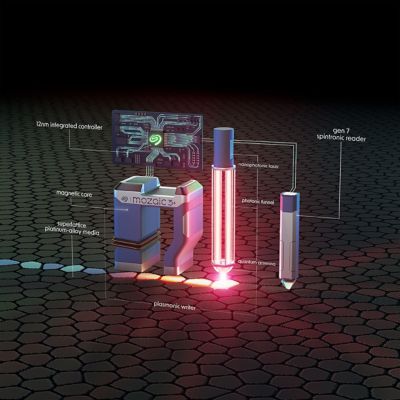

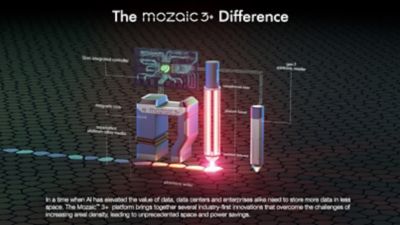

To meet growing demands sustainably, Seagate Technology, a leader in mass-capacity data storage solutions, is leveraging Ansys simulation and NVIDIA technology to develop future generations of its Mozaic hard drive technology. The current platform, Mozaic 3+, delivers mass-capacity storage at unrivaled areal densities of 3TB per platter. Anticipated models Mozaic 4+ and Mozaic 5+ will store 4TB and 5TB of data per platter, respectively. The Mozaic 3+ platform currently powers Seagate’s Exos hard drives, which boast a capacity of up to 32TB.

With the support of Ansys and NVIDIA, Seagate enables its Mozaic technology to store data at previously unachievable levels without increasing power consumption. By integrating Ansys Fluent fluid simulation software and NVIDIA’s accelerated compute power, Seagate optimizes and accelerates designs up to 50 times faster, increases efficiency, and drives down costs, enabling greater mass data storage solutions for emerging AI-related data needs.

Exos Mozaic 3+ hard drives hold up to 32 terabytes (TB) of data.

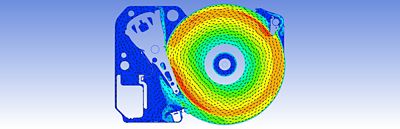

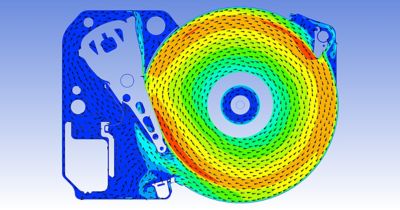

A computational fluid dynamics (CFD) simulation of a hard drive’s internal flow velocity in the Ansys Fluent platform. Image: Seagate Technology.

Optimizing CFD With GPU Compute Power

Since its founding over 45 years ago, Seagate has produced more than 4 billion TB of data capacity and currently offers a full portfolio of storage devices, systems, and services. Recognizing today’s storage demands in the face of expanding AI technologies, Seagate uses simulation and accelerated compute power to amplify design and development.

Specifically, by combining Fluent software computational fluid dynamics (CFD) simulation and an NVIDIA DGX system, Seagate dramatically reduces model solve times for significant design optimization and increased productivity.

Fluent software simulation offers a transformative feature for engineers seeking to speed up CFD simulations with accelerated computing: a native multi-graphics processing unit (GPU) solver. A native implementation harnesses the full potential of NVIDIA accelerated computing for CFD by running the solver code resident on multiple GPUs. With this capability, Fluent CFD software drives impressive savings in simulation time, hardware costs, and power consumption compared with traditional central processing unit (CPU)-driven solvers. (Learn more about the Fluent software GPU solver.)

Before adopting Ansys and NVIDIA technology, Seagate’s hardware included a workstation comprising 40 core CPUs, resulting in a time-consuming, cumbersome workflow. Seagate’s CPU-based workstation runtimes were approximately one month for chassis-level aeroacoustics models with a mesh size of about 50 million cells while finer, higher-quality mesh containing up to 100 million cells took even longer.

Today, the company runs Fluent software models on an NVIDIA DGX system.

“With NVIDIA DGX and Ansys Fluent software, we are able to reduce the runtimes of our internal drive flow models from hours to minutes, approximately a 50 times improvement,” says Kent Forbord, senior director of advanced mechanical development at Seagate. “With NVIDIA DGX and Ansys Fluent software, we are able to reduce external aeroacoustics model runtimes from one month to less than one day. The end benefit of reduced solve times is the ability to evaluate more designs over a shorter period of time, ultimately achieving a more optimal design.”

Building a Future Generation of Hard Drives

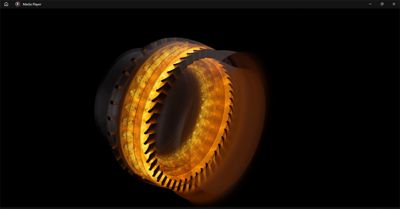

Seagate is developing future generations of its Mozaic hard drives, which are standouts when it comes to areal density and incorporate the company’s unique implementation of heat-assisted magnetic recording (HAMR). Also referred to as area or surface density, areal density is essentially a measurement of the storage capacity per square inch of an object’s surface.

According to Seagate, although adding more disks to a hard drive could increase capacity, it’s not efficient. For starters, each disk in a hard drive requires many materials. This not only increases overall material usage but raises power consumption. On the other hand, increasing areal density enables each disk to hold more data without using more material or disks, offering a more efficient approach. Basically, it’s about storage quality, not quantity.

Forthcoming Seagate hard drive models Mozaic 4+ and Mozaic 5+ will be able to store 4TB and 5TB of data per disk, respectively.

Tracks are the circular rings, or bands, on a hard disk that store data. Achieving higher track densities is a critical target for Seagate’s forthcoming HAMR-enabled platforms Mozaic 4+, which is in development, and Mozaic 5+, which is being demonstrated in lab tests.

To increase track densities, Seagate engineers use Fluent software simulation to assess and optimize key airflow metrics in the drive, such as particle transport, windage drag, and structure excitation.

At the system level, they model the dynamic excitation on the outside of the drive, temperature, and pressure drop to assess cooling flow throughout the system. Thermal analysis is important in designing efficient, safe hard drives. The team also performs aeroacoustics simulation — the modeling of sound generated from a flowing fluid — to improve system chassis and fan designs.

Mozaic drives enable data centers to store more data in the same space, offering more compute power with a smaller footprint and reduced total cost of ownership (TCO) for customers. Keeping things compact, the drives bear the same 3.5-inch form factor as Seagate’s earlier hard drives and use the most advanced materials, including a superlattice platinum-alloy media that combats magnetic instability at the nanoscale.

Additionally, the GPU-powered simulation workflow reduces material and power usage while speeding up design.

“Through more upfront modeling and design optimization, Seagate engineers reduce prototyping and physical testing,” Forbord says. “This helps them meet the ultimate goal of shortening our design cycle.”

Designed with the most advanced materials and structures, Seagate’s Mozaic drives enable data centers to store more data in less space more efficiently.

Speeding Up Data Storage for an AI Boom

Mozaic-enabled drives are making a substantial difference in the industry. With greater areal density, the hard drives store more data in the same space, and with an upgraded workflow, Seagate produces more drives at a faster rate.

“When the models ran about one month, that made them impossible to use as a design tool,” Forbord says. “Integrating Ansys and NVIDIA technologies enables our team to streamline the innovation process and meaningfully speed up time to market.”

With regard to the AI-related data explosion, Seagate is ready.

“Hard drives, which amount to 90% of cloud data centers, are going to be key to storing the masses of pre- and post-AI analysis data that are going to fuel the current data economy,” Forbord adds. “Seagate areal density innovations like the Mozaic platform keep driving the TCO of storage down, enabling more data to be stored for AI models to use pre- and post-analysis.”

To explore the potential of Fluent software CFD firsthand, request a free trial. Learn more about the latest updates to the Fluent software GPU solver in the 2024 R1 on-demand webinar.

Just for you. We have some additional resources you may enjoy.

“With NVIDIA DGX and Ansys Fluent software, we are able to reduce the runtimes of our internal drive flow models from hours to minutes, approximately a 50 times improvement.”

— Kent Forbord, Senior Director of Advanced Mechanical Development at Seagate

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.