-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

June 29, 2023

Overcoming Engineering Challenges in the Pursuit of Sustainable Propulsion

The commercial aviation industry will be defined in the coming decades by its pursuit of more sustainable propulsion systems. But as industry works to define and develop these new designs, they will have to overcome significant and varied engineering challenges. To do so, they must rely on engineering solutions that streamline the design process, improve product performance, and reduce costly development delays.

A Multitrack, Multi-timeline Approach

Initially, commercial aviation companies explored the possibility of improving aircraft sustainability by transitioning from traditional combustion engines to electric propulsion systems. However, the limitations of existing battery technology made that transition impossible in the near term. In light of this, the industry is taking a segmented approach to propulsion system development. This approach will allow them to achieve real improvements in sustainability in the short term in the form of hybrid-electric systems while simultaneously pursuing more energy-efficient electric and hydrogen-based systems. This multitrack, multi-timeline approach also enables aviation companies to innovate and discover other applications and markets for their products.

As they pursue these breakthroughs, aviation engineers must also contend with the numerous technical challenges a multidiscipline system design process presents. This post will highlight those challenges and explore how digital engineering solutions can help overcome them.

The Engineering Challenges of Sustainable Propulsion

Every complex product presents its own engineering challenges, but new aircraft propulsion systems are both incredibly complex and reliant on still-maturing technology. That means that the engineering challenges will require multidisciplinary solutions and tradeoffs and the system must be assed as a whole. Some of these challenges include:

- Electric drivetrain and systems integration. Engineers must define optimal system architectures with integrated embedded controls. They must also develop extensive requirements for thermal management, power management, and ensure the system is designed to be inherently safe.

- Electric machine design. Defining and designing new propulsion systems require that engineers make trade-offs to satisfy competing requirements while optimizing the system’s safety and efficiency. A design powerful enough for a large passenger plane may create thermal management problems that require a more powerful cooling system, which means more weight and could therefore affect its range. Engineers must balance these trade-offs carefully as they pursue viable systems.

- Energy storage and distribution. Electric propulsion systems and hydrogen-based systems pose different problems. Electric systems with batteries must store and discharge energy without unduly affecting the system’s power management controls. Hydrogen-based systems will most likely be fueled by hydrogen liquid that must be stored at temperatures of -250 °C and can flow safely through the system to the fuel cell, where it can be converted into electricity.

- Power electronics and control design. Engineers must ensure that new propulsion systems can manage their power electronics for different load conditions while ensuring high-power performance. Condition and load-adaptive control software and hardware is needed that can accommodate the high-frequency switching and complies with certification standards. Design teams must prevent electromagnetic interference with onboard components during any stage of the flight cycle.

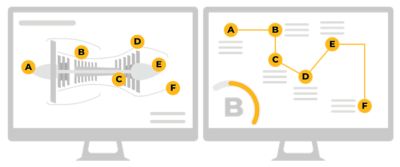

Electric drivetrain and systems integration: Ansys solutions allow engineers to model a design and simulate its performance so they can refine system architectures and satisfy the system's competing requirements.

Overcoming Challenges with Insights

Traditional product development tools, which often rely on disconnected spreadsheets, documents, and email messages, served companies well enough when they were updating and iterating upon existing propulsion systems in previous decades. But developing entirely new propulsion systems requires a fresh approach. Whatever engineering difficulties aviation companies face in the pursuit of more sustainable flight, digital engineering solutions provide a path to overcoming them.

Power electronics and control design: Ansys tools' simulation capabilities allow engineers to analyze a propulsion system's performance during various power cycles to ensure its thermal and electromagnetic effects do not cause safety issues.

These more advanced solutions can provide engineering teams with greater insight into a design’s performance earlier in development, which allows them to iterate — and innovate — more rapidly. These insights enable engineers to make more fully informed decisions as they optimize system architectures, select effective materials, and balance engineering trade-offs. As a result, they can reduce design errors and lower the number of prototypes that must be built and tested to establish a viable design. This shortens the design cycle, reduces costs, and ultimately results in a better product.

Empowering Aviation Companies with Cutting-Edge Engineering Solutions

Ansys solutions provide aviation companies with the capabilities they need to tackle the engineering challenges inherent to sustainable propulsion system design. Engineers can use these solutions to model and analyze system behaviors from the earliest stages of development and quickly adjust to ensure optimal performance, capturing the design rationale and making it traceable in a way that evolves with the product life cycle. It will be these solutions that enable design teams to identify a system’s functional and safety requirements early on, which means they can address potential failures through design or control software and guide the design toward certification more rapidly.

Engineers can also utilize Ansys solutions’ electric machine templates, which provide ready-made starting points for the development of unique designs. In addition, they can leverage integrated simulation workflow solution capabilities to analyze across disciplines and ensure that all subsystems interact safely and effectively in all of their required operational configurations.

Ansys is aligning its digital engineering solutions so that engineers can integrate into the transformation that aviation companies are working toward as they strive to reduce the industry’s environmental footprint. But whether they are working to improve fuel cell designs, simulate a battery’s thermal performance, or optimize and integrate complex system architectures, these solutions can help them do so more efficiently, quickly, and cost effectively than traditional methods.

There is no doubt that sustainability is driving the future of commercial aviation. What is less certain is which companies will play the biggest roles in making that future a reality. The stakes are high for the industry and the environment alike.

Seize the Future of Sustainable Aviation

Aviation companies that can define and develop new highly complex propulsion systems quickly and bring high-quality products to market ahead of the competition will have a tremendous advantage in the race to net-zero. Ansys can provide these companies with many of the tools and integrate into the digital frameworks needed to overcome the complex engineering issues these products present and establish a lead in that race.

Read the white paper “Hybrid & Electric Propulsion Systems for Sustainable Aviation” to learn about the drivers, technical challenges, and solutions for these next-generation propulsion systems.