-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

May 24, 2021

Moffitt Keeps Manufacturing Plants Cool Using Ansys Simulation

Floor-level temperatures in a steel mill can reach 120 F, an uncomfortably hot temperature for humans to endure for any amount of time, let alone for an eight-hour shift. Moffitt Corporation designs and manufactures custom cooling systems for mills and many other workplaces to keep workers at more bearable temperatures using Ansys Discovery’s near-instant thermal flow simulations.

Discovery not only speeds up the design process with its rapid simulations, it also helps Moffitt to make the sale by giving their prospective customers a visual depiction of their solution.

“People can’t see air,” says Mike Berry, Vice President of Operations and Engineering at Moffitt, “and many aren’t interested in any mathematical solutions we might show them. Ansys Discovery lets them see air through a video depiction of the airflow streams and the temperatures throughout the building. That's what sells the job, and it really sets us apart from our competition.”

Educating Customers About Cooling Using Simulation

It turns out that most customers’ initial ideas of how to cool a large plant are usually the same — and wrong. Their inclination is to put huge exhaust fans on the roof and just pull the hot air out. They may add passive intake air louvers down low on the floor for replacement air. “Basically, what we do is take that whole system and turn it upside down,” Berry says. “We have passive exhaust from the roof and powerful intake fans lower down, so you're bringing in the cold air at floor level where people are working and you can filter that air if you need to, for your process.”

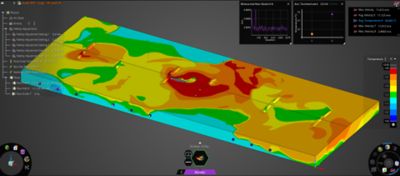

Simuation data from Ansys Discovery helps Moffitt convince skeptical customers to cool their manufacturing plants in innovative ways.

While they may be skeptical at first, Moffitt’s meticulous approach to modeling the building and the resulting simulation data from Discovery prove to prospective customers that this is the right way to go. Starting with blueprints of the building and the layout of equipment, Computational Fluid Dynamics Engineer Lisandri Neziraj builds a 3D model of the plant in Discovery and begins to establish baseline thermal conditions using thermal CFD simulations.

“We show them the model and where their heat loads are, and we'll cut a plane at 5 feet to show them their floor temperature,” Neziraj says. “And they'll look at it and say, ‘Oh yeah, that area over there, that one's always hot. You guys nailed that.’"

Nailing the details of a prospective customer’s plant goes a long way toward convincing them that Moffitt engineers know what they are doing.

“Once they see how accurate our model is down to the details, we show them a version with our recommended cooling equipment installed in the model of the building,” Berry says. “When they see that we’ve lowered the average building temperature by 20 degrees, that can seal the deal.”

Software Evolution Is the Key

Moffitt originally used another company’s CFD solution, until a colleague saw a demonstration of Discovery. “You've got to see this. This is going to change everything," Berry recalls the colleague saying.

Soon they went from one person knowing how to run CFD, who was overwhelmed by the workload, to six people running CFD in between other job assignments. Business was so good they still couldn’t keep up, so they hired Neziraj to work on CFD simulations full time. He’s always busy, but is keeping up with the workload thanks to his expertise and improvements in Discovery.

One of the reasons he is able to keep pace is that Ansys is committed to continuously improving its simulation software in response to customers’ needs. Originally, engineers who wanted to go from Discovery’s near real-time simulations to a full-featured CFD simulation for added accuracy had to use two Ansys programs with different user interfaces and transport the data between products. That problem was solved with a new release of Ansys software late in 2020, which combined both solvers into Discovery as “Explore” and “Refine” modes for quick, seamless data transfer using a single user interface.

The Refine mode, which leverages the trusted Ansys Fluent solver, also made it possible to save complete simulation results in Discovery for the first time.

“In the original Discovery [now called the Explore mode] we could run many simulations quickly, but it was difficult to leverage those results in another software package,” Neziraj says. “Many times, the customer would ask a question and maybe we didn't have the right screenshot of the data and we'd have to rerun the simulation. Now, we can stay in the same user interface and transfer the model from Explore into Refine mode. Being able to get a more consistent solve and to save those results was something that got me really excited.”

Ansys’ willingness to make improvements that Moffitt “wanted and needed” has led them to use the Refine mode “as our gold standard to show to the customer,” says Neziraj. “But having the Explore mode’s capability to see results in real time, to verify that if things are working properly right away, saves us so much time. So, I think they work great paired together.”