-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

May 7, 2021

How one Air Race E team Overcame a Critical Design Challenge With Simulation

The clock is ticking with just a few months to go before the first Air Race E qualifying races. The teams competing in the first all-electric airplane race series are under significant time pressure to complete the design and manufacture of their aircraft. Everything must now go according to schedule.

In a previous blog, we described the progress that Team Pie Aeronefs of Switzerland had made this year in designing and building the fiberglass fuselage of their aircraft for physical testing. As we continue to chart their progress to the start line, we learned how simulation helped identify a potentially showstopping design challenge and, crucially, how to fix it.

The “Stress” of Building a Performance Aircraft

Members of Team Pie Aeronefs work on the ailerons for the first Air Race E qualifying races.

With the fuselage almost complete, before moving on to a full build of the wings, the team decided to work on the ailerons. Ailerons are panels located near the ends of the wings that move up or down to control the roll of the plane or allow the pilot to execute a banking motion to make the plane turn. Team Pie Aeronefs engineers are working on ailerons with 19 components, making them “quite complex,” according to Timothy Kriegers, Chief Marketing Officer and Sponsorship Outreach for the team.

This complexity is what delivers race winning potential. To put this in context “with our aileron design, the roll rate at maximum speed is enormous,” Kriegers says. “If you put full deflection on one side you can make one turn in one second.” With such incredible agility comes incredible forces.

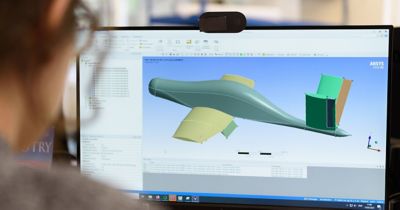

Simulation helped Team Pie Aeronefs of Switzerland identify a critical design problem in their Air Race E aircraft design.

The team turned to simulation to help them understand how their proposed design would perform under these conditions. The engineers performed a finite element analysis (FEA) of the aileron assembly using Ansys Mechanical. The simulation revealed an unexpected and critical second-order failure mode due to combined flexion and torsion of the aileron spar, the primary structural element of the assembly.

To overcome this, they reinforced the spar appropriately and eliminated the failure mode.

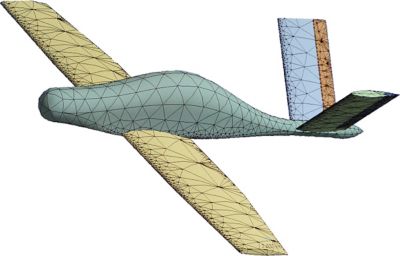

A mesh of the Air Race E aircraft designed by Team Pie Aeronefs.

Simulation Provides Manufacturing Confidence

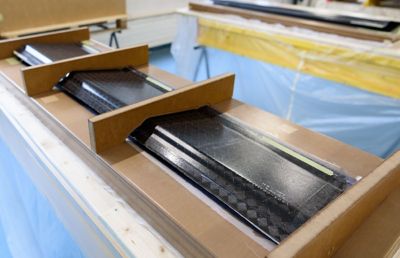

With time of the essence, identifying this problem upfront meant that the team could progress to manufacturing the aileron with confidence. They built the aileron skin structure using a layer of carbon fiber followed by a honeycomb structure for stiffness and then another layer of carbon fiber. The process is time-consuming because of the separate steps and overnight waits involved.

“We put down a layer of the carbon fiber and seal it in a vacuum bag for one night, open it, then put the honeycomb everywhere, seal the vacuum bag overnight again, open it to add another layer of carbon fiber, and seal the vacuum bag for yet another overnight curing period,” Kriegers explains.

If simulation had not been used, the critical design problem would have gone undetected until much later in the process and all the days taken to manufacture the aileron would have been wasted – potentially threatening their ability to deliver an aircraft to the start line.

Team Pie Aeronefs built the aileron skin structure with carbon fiber after simulating the design.

Now the team is working on the other components of the ailerons, including the pushrods, a counterweight and an enclosure, which will be made of wood. The original plan was to use carbon fiber or aluminum for the enclosure, but it is quite small and to save some time they decided to use wood for its ease of manufacture without sacrificing strength. The complete aileron assembly with the counterweight is going to weigh 1.8 kg out of a total permitted load of 400 kg, so it’s “quite stiff, quite robust,” according to Kriegers.

Electric Aircraft Engineers Design a Comfortable Cockpit

As with all motorsport, winning an air race requires the aircraft and pilot to be in perfect harmony. Pie Aeronefs SA engineers hollowed out the cockpit section of the fiberglass test fuselage to see if any adjustments were required to fit the pilot comfortably and give him access to all the controls. Marc Umbricht, the CEO, Technical Director and pilot of the team, climbed into this makeshift cockpit to try it on for size.

“We need to increase the height of the fuselage a little to accommodate the pilot’s helmet, and also widen it by about 10 cm to give him more room for the controls,” says Kriegers. The drag on the fuselage in this area is not large, so making these adjustments will have little effect on the speed of the airplane. “Umbricht is quite happy with it, and he is the one who is going to fly it,” Kriegers says.

What’s Next for Team Pie Aeronefs SA?

With high performing ailerons and a happy pilot, the team is moving on to the wings. All molds are ready for wing construction, so they will begin the infusion of the upper skin of the wing very soon. Again, they will spend a couple weeks on each part, performing the layering of carbon fibers and honeycombs and vacuum sealing them overnight, as explained for the ailerons above.

When the electric motor arrives, they will test its fit in the fiberglass fuselage. Once all dimensions for the fuselage have been determined, they will start building the carbon fiber fuselage that will be used in the race plane.

This puts them right on track to keep to the timeline and have their plane ready for the first qualifying event later this year. “There is still a lot of work to do,” says Kriegers, “but at this point we are confident that we are on the right track.”

To learn more, view the webinar, Electrothermal Simulations of High-Power Electric Machines for Reliable Electric Aircraft.