-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

February 04, 2020

Never Underestimate the Remarkable Benefits of Corrugated Iron

In a world full of new and exciting super materials, we can sometimes lose sight of some that have already changed the world and stood the test of time.

For instance, take corrugated iron. It’s become so commonplace and anonymous that people can walk past it without noticing.

A beautiful home made of corrugated iron

The truth is corrugated iron is a super material composed of a zinc-dipped — or galvanized — mild steel sheet. The sheet is then passed through gear-shaped rollers to create a repeating, almost sinusoidal, pattern.

The materials, pattern and manufacturing process make the sheet strong, light, affordable, biodegradable and even bioavailable. So, it’s an excellent choice for engineers looking to utilize eco-friendly structural components.

The pattern gives the sheet bending stiffness about the axis normal to the corrugations. This means that the material can be used for self-supporting wall panels.

Alternatively, the sheet could be given an additional curvature about its second axis to create a shell that is stiff and strong about any axis of bending. This makes the sheet an ideal material to create wide-spanning roofs without rafters and purlins.

The History of Corrugated Iron

When Henry Robinson Palmer registered a patent for corrugated iron in 1829, he had no idea the impact it would make on world history. After all, not every material finds a profitable application. And those that do face stiff competition in the construction industry. Typically, it could take decades before a new material sees commercial success.

However, by the 1830s corrugated iron was being used in commercial buildings, roofs and cladding for walls and lights. Years later, it was being exported as build-it-yourself prefabricated structures that were made for easy assembly and disassembly.

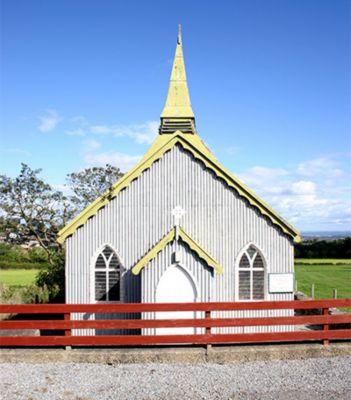

A church made from corrugated iron

This made it simple to build, repurpose or relocate metal parts or structures as needed. Eventually, materials for homes, religious buildings, hangars, shops, hospitals, small towns and colonies were being shipped around the world.

In modern times, the material’s portability and rapid assembly has enabled it to provide affordable shelters for those in developing regions and disaster relief scenarios. Its affordability has also made it a choice material for those working on pet projects or custom homes.

Nonetheless, corrugated iron experienced a lull in popularity around the 1980s. It was seen by some as a temporary stand-in.

However, people are starting to appreciate the material for its historical, agricultural and life changing abilities. Corrugated iron is once again a choice material for retro, environmentally friendly and rustic designs.

Knowing about materials is a vital part of any engineering, design, or physical science degree. To find out how Ansys Granta provides teaching resources that can help engineering educators to teach university and college students about materials, read about Granta EduPack.

Any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans such as Ansys and Ansys Granta are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries.