-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

September 18, 2023

Automotive Electrification Heats Up the Engineering Challenge for STMicroelectronics

The global automotive industry has centered its attention on the internal combustion engine for over a century. However, a transformative shift is now underway, driven by the compelling demands of government regulators and consumers alike for high-performing, energy-efficient, sustainable, and affordable electric vehicle (EV) designs. U.S. President Joe Biden has defined a set of ambitious goals for EVs, including a target for half of all cars sold in America to be electrically powered by 2030. The European Parliament and Council has created an even more ambitious goal for all new registered cars to be zero-emissions by 2035, with gradual emissions reductions in the meantime. Clearly, this creates an enormous market opportunity. In fact, sales of EVs are projected to reach $823.75 billion by 2030, reflecting an annual growth rate of 18.2%.

As car makers race to bring cutting-edge EV designs to market and gain a competitive edge, their supplier networks are under escalating pressure. Among the critical components that have come to the forefront, semiconductors have emerged as a driving force. As vehicles evolve to be more connected, autonomous, and electric, semiconductors have increasingly assumed a central role, often surpassing steel and rubber as the backbone of the modern automotive industry.

In the present day, car makers are seeking more than just individual chips from their semiconductor partners. They are increasingly relying on fully realized modules or systems that can be seamlessly integrated into their EV designs, streamlining their development timelines and reducing internal engineering costs, while optimizing their manufacturing and logistics processes. This entails not only the chips themselves but also any related components that are necessary for maximizing the overall performance of semiconductors.

Plugging Into New Engineering Capabilities

ST, a leading supplier of semiconductor technologies to the global automotive industry, recently designed a power module for EV powertrains using holistic chip architecture, which included a new component — a cooling jacket. This integrated heat sink ensures optimal performance of the power module, managing thermal gains and minimizing conjugate heat transfer to the larger electric powertrain.

The challenge? Given the time pressures — and the mission-critical nature of the holistic chip architecture for an electric powertrain module, ST engineers recognized that thermal simulation should play a central role in the development phase. Teaming up with the University of Catania in Italy, where a team of researchers headed by Professor Stefano Mauro were working at the leading edge of computational fluid dynamics (CFD), the simulation engineers began to test a new cooling jacket design that would minimize any conjugate heat transfer related to the densely packed, powerful module.

Driving World-Class Product Innovation with Ansys Fluent

From the early development stages of this new power module, ST’s simulation team and researchers used Ansys Fluent software.

“In designing an all-new system like this, you need to look at every possible contributor to cooling efficiency — from the base material and the surface texture to the fluid characteristics and behaviors once coolant is added to the design,” Professor Mauro explains. “It’s impossible to physically see inside a cooling chamber, or to build and test hundreds of physical prototypes. Fluent enables us to simulate the cooling jacket’s standalone performance, as well as its contribution to the larger power module, in a virtual environment. It enables us to optimize and verify the heat sink’s reliability in a way that’s extremely fast, efficient, and cost-effective.”

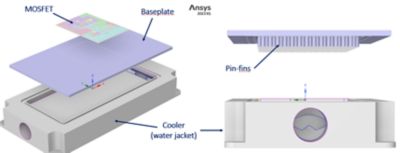

A mesh geometry of the metal–oxide–semiconductor field-effect transistor (MOSFET) was constructed, along with the module baseplate that would hold it. Then researchers constructed a cooling jacket, or heat sink, that was pinned underneath the base plate. They simulated the flows of a 50-50 mixture of water and ethylene glycol inside the cooling jacket, using a set of predefined boundary conditions and Fluent solver settings.

ST’s power module product design includes a MOSFET mounted on a baseplate that functions as a power unit. Underneath is a water jacket that serves as the unit’s continuous cooling system.

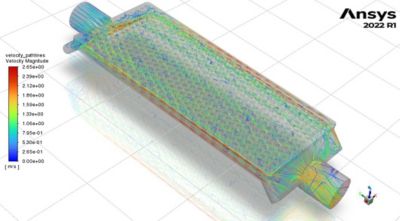

Much of the team’s simulation efforts focused on optimizing the overall geometry of the heat sink by visualizing fluid flows as the water and ethylene glycol mixture flowed through the power module, looking for places where problems such as turbulence and eddying could occur. Researchers looked at the number of input and output holes in the power module, as well as the shape and size of flow channels. A key focus was reducing pressure drops that would lessen the effectiveness of the cooling process. Ansys SpaceClaim software enabled the team to quickly create geometric variants and then study the effects of changes in geometry on critical elements such as inputs and outputs.

Through Fluent's post-processing capabilities, the simulation engineers could see how flows develop and progress within the power module as they pass through various inputs, outputs, and channels. Issues such as pressure drops could be easily identified and addressed.

Fluent Meshing software enabled the research team to easily optimize the computational mesh to achieve the best compromise between accuracy and calculation time.

Thanks to Fluent’s solver capabilities, the simulation team also conducted in-depth studies of the impact of surface texture inside the heat sink. They began with a completely smooth surface and then gradually added roughness to assess the associated impact on internal fluid flows and cooling effectiveness. It seemed intuitive that a smooth surface would facilitate smooth coolant flows, with minimal losses and pressure drops. However, the team discovered that there was actually less separation of the fluid flow as surface roughness increased. They were able to iteratively optimize the surface texture via Fluent simulations to support the most effective cooling flows.

“Our findings about surface roughness were surprising and actually represented good news for the product development team, because fine processing can be very expensive,” notes Professor Mauro. “Within days, we were able to make many important discoveries about cooling effectiveness and verify the final design.”

“We were very impressed by the capabilities of Ansys Fluent to rapidly and accurately solve this new engineering challenge for us,” states Daniela Cavallaro, CAD & Modeling Team Leader in the Power Transistor sub-Group, STMicroelectronics. With a large and robust internal R&D team, ST uses many Ansys solutions, especially in the area of electromagnetics, exploring new concepts in fluid dynamics that will prove essential as the company explores additional cooling applications.