-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

When thinking of environmental impacts in industry terms, the conversation in the automotive world often shifts to vehicle efficiency and sustainability. Yet there are other pressing needs that can be captured under a much wider umbrella that encompass not just electrified and autonomous technologies but internal combustion vehicles.

One crucial aspect related to all three is the impact of noise, vibration, and harshness (NVH) on our environment. Most of us expect a quiet experience on the road regardless of what we are driving, with good reason. Excessive interior cabin noise can lead to headaches, fatigue, and stress, jeopardizing occupant health and well-being.

Sanden International is focused on producing mechanical and electric A/C compressors for automotive customers designed to keep things equally cool and quiet during our time on the road — cool in that they help ensure that the A/C is functioning as intended to keep things comfortable, without introducing additional noise into the cabin. And they use a variety of Ansys simulation solutions to do this.

“We have to provide our customers with high-performance, quiet, reliable products that are lightweight and economical in a short period of time,” says Olivier Derollepot, computer-aided engineering (CAE) manager at Sanden. “This particularly applies to the electric compressor, where, in an electric vehicle, the level of silence is such that the NVH requirements for the compressor are pretty drastic. That’s where Ansys fits in. We use a lot of Ansys products to be able to develop our electric compressors in a short amount of time.”

Echoing the Sound of Silence With Simulation

When it comes to interference from an A/C compressor, how loud is too loud? Automotive research suggests that tonal sounds from A/C noise are audible once they surpass vehicle engine noise (masking noise) by 7 to 9 decibels.

Simulation Clamps Down on Quality

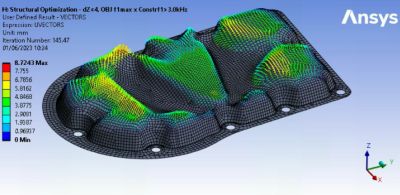

Sanden recently designed a noise, vibration, and harshness (NVH) bracket and optimized it for fellow colleagues from the NVH group at Sanden to ensure consistent results on the test bench. The intention in designing it was to avoid having any results polluted by the dynamic response of the jig itself. Using the bracket, the team avoided testing the bench in favor of testing the product on it.

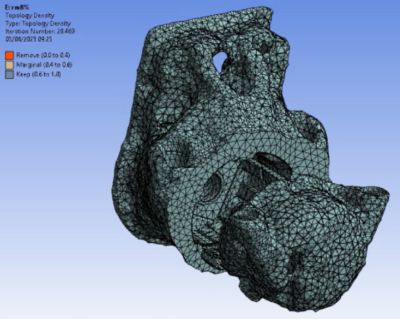

“We used Ansys Mechanical software’s topological optimization model to design clamping devices for our assembly machines at the plant,” says Olivier Derollepot, computer-aided engineering (CAE) manager at Sanden. “Sometimes we simulate clamps to see how they can best hold a piece in place when machining it while minimizing any slippage or excessive deformation. It helps us understand what the consequence would be for the final product if we clamp a piece in a certain way. This activity is directly related to the internal quality of our plants, limiting inefficiencies that lead to excess scrap during production.”

Sanden subject matter experts Olivier Derollepot, computer-aided engineering (CAE) manager (right), and co-presenter Arnaud Menon, CAE senior engineer (left), at the 2024 Ansys France Convention. Both have a strong expertise in structure dynamics and acoustics.

The main pathway for this noise is, in fact, the A/C system compressor via solid-borne (structural) and airborne pathways, with acoustic performance during engine idling and run-up being critical to passenger comfort. Fluid interactions during cooling are also conveyed to the cabin in the process.

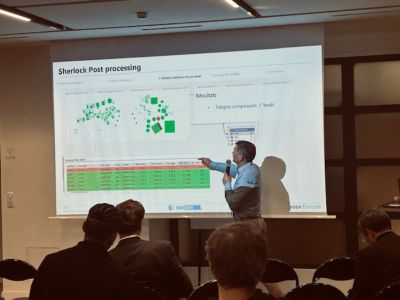

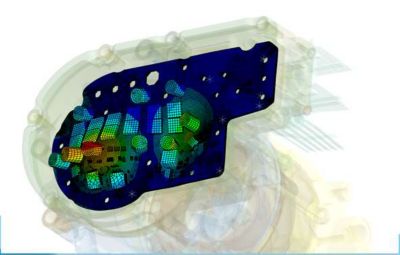

Left: eigenmode deformed shape of a printed circuit board (PCB), Ansys Mechanical/Sherlock software vibration durability analysis. Right: topography optimization of a stamped plate in Mechanical software, with noise, vibration, and harshness (NVH) target.

Sanden relies on Ansys simulation to address three types of noise generated by its A/C compressors:

- Solid-borne noise, or vibrations that the product is generating to the vehicle body. Ansys Mechanical structural finite element analysis software enables users to apply internal mechanical loads generated by the compressor as mechanical inputs to structural 3D models to better understand these vibrations in a virtual environment.

- Airborne noise that is directly heard from the compressor running on a bench. Adding an acoustic layer around the dynamic structural 3D model in Mechanical software enables the direct evaluation of noises radiating around the compressor. Additionally, various physics via the Ansys Workbench simulation integration platform support acoustic optimization of different structures.

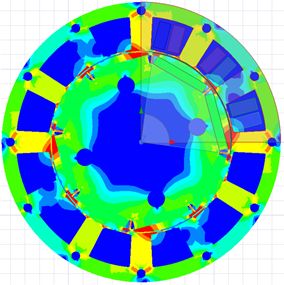

- Fluid-borne noise involving the propagation of acoustic waves through the pipes, as the entire system requires the circulation of refrigerant in a loop. Using a Mechanical 3D model as a base, a layer of topical optimization can be added to capture any irregularities. Additionally, the Ansys Maxwell advanced electromagnetic field solver can be used to address excitation of the structure from the electric motor responsible for rotor winding.

Left: topological optimization of casings in Mechanical software, with NVH target. Right: electric motor analysis in the Ansys Motor-CAD dedicated electric motor design tool for multiphysics simulation.

Pressed for Time, Not Solutions

For Derollepot and team, the challenges of designing and testing A/C compressors begin with a request for quotation (RfQ). Typically, at this stage, they must propose a product draft in a very short lead time, with the right specs at the right price. Every design must be lighter than 6 kg and fit within certain packaging without exceeding a specified number of decibels under specified operational conditions. Responding in a reliable way to these requests requires fast-running, reliable tools — namely, Ansys simulation software — to do the necessary evaluations prior to prototyping.

Most of the issues that the team regularly faces are related to durability, like how a product will react to an external vibration source. Ansys Sherlock electronics reliability prediction software helps the team accurately test the entire compressor assembly to better understand these types of interactions. The team can also use the software to drill down on the individual elements of the compressor, which includes a stand-alone control board.

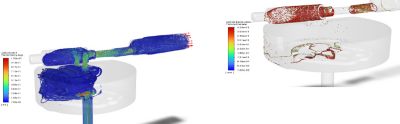

Left: steady-state gas flow in an oil separator in Ansys Fluent fluid simulation software: gas velocity. Right: liquid particle phase injection in a steady-state gas flow in an oil separator in Fluent software: particle trajectories.

For instance, to control the mass flow rate, or the ratio of absolute discharge pressure to the absolute suction pressure of the refrigerant gas coming out of the compressor, requires controlling the electric motor’s rotation speed. One of the main issues related to this function is the vibration durability of electronic components, including the control board.

“It’s hard to believe now, but before Sherlock software, we would draw the control board, make a prototype, and put it on the test rig,” says Derollepot. “Then we would observe the failure, try to figure out where the failure comes from, then redesign the control board, make a new prototype, and test again. It was time-consuming and money-consuming. Now, every time we release a prototype of the control board, the vibration test looks like a confirmation of what we already know. No failure.”

Every day, engineers like Derollepot are turning to Mechanical software to solve big challenges in automotive NVH. Check out the latest updates to one of our most popular tools.

Just for you. We have some additional resources you may enjoy.

“We use a lot of Ansys products to be able to develop our electric compressors in a short amount of time.”

— Olivier Derollepot, computer-aided engineering manager, Sanden

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.