-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

March 18, 2022

Ansys Forming Provides a One-Stop Shop for Metal Stamping

Engineers across the metal stamping industry may now be able to take an extended lunch. Ansys has just released its first metal stamping simulation software, an all-inclusive product that meets multiple industry needs within a single platform, slashing time and costs.

Sheet metal processing or fabrication is used in a wide scope of industries from automotive, aerospace, and electronics to construction, medical, and more. Forming, also referred to as metal deformation, is a set of fabrication processes that manipulate the metal without cutting it. There are a number of forming processes, including bending, stamping, and spinning, and each can be used for tasks like flanging or hemming. Essentially, any manufacturer or construction company converting slabs of sheet metal into functioning parts is engaged with some form of sheet metal processing. Yet physical prototyping during the meticulous sheet metal fabrication process is time-consuming and costly, with challenges frequently arising.

Ansys Forming greatly reduces all of these woes, allowing you to simulate, digitally design, and validate every step of the sheet metal forming process with speed and accuracy. It provides a streamlined, end-to-end workflow and the fastest solve time for methods and die shop engineers. There’s also an added level of security with the software backed by the trusted solver, Ansys LS-DYNA.

Stamping Out Challenges with Ansys Forming

Formability, surface defects, and springback are just three of the top challenges facing engineers in the sheet metal processing industry. Like its name suggests, formability involves the ability of sheet metal to be formed without imperfections like buckling, wrinkling, necking, or cracking.

Surface defects may include any of the above-mentioned nuisances or just unevenness, which is an equal hindrance to design and often occurs due to the misuse of the stamping die, or tool, used to shape the metal.

Springback is possibly the most frustrating pain point because it happens after the forming process is completed due to the elastic recovery of bent parts. This means that even after you complete the task and your metal is in the form you wish, it can snap back toward its original shape if you don’t account for the springback factor. The springback factor is the number of degrees that the metal will likely “spring back” and is traditionally calculated by performing test bends.

Ansys Forming eliminates this trial-and-error type of physical testing with digital validation through simulation, which enables early-stage and detailed design configurations more seamlessly, accurately, and quickly.

What’s more, you don’t have to be a finite elements analysis (FEA) expert to run simulations in Ansys Forming.

With an intuitive and easy-to-use graphical user interface (GUI) you can effortlessly setup your simulations, monitor your jobs, and analyze your results with many parameters predefined for straightforward selection. The software speaks the language of the methods engineer, simplifying tasks and requiring minimal input while following the natural die and design process. Even complex tool movements like blanking, which involves using a mold to separate the metal you are working on from the larger sheet metal, can be defined within the software to simulate the whole process.

Further, you can preset varying simulation needs, including formability and springback prediction as well as feasibility to determine or ensure that your project is technically feasible from its earliest stage. This convenient setup supports an efficient workflow that gets you results for multiple iterations faster and easier.

The software’s usability not only cuts time and cost but also increases the usage of simulation within your team because anyone can learn the interface. This wider adoption of process simulation can accelerate your development time and reduce human error, which improves product efficiency in a fraction of the time and cost usually expended.

Through a deeper integration of pre- and post-processing in combination with the solver, Ansys Forming assembles your tasks within one software application, offering functionality at every turn with convenience and quicker results.

Forming Faster Solutions

To understand the scope of sheet metal processing and tasks, think of the detailed curvature and unique design of the fender of an automobile, wing of an airplane, or even the frame of a bicycle. But it’s not just transportation. From the cans in your cupboard to your kitchen sink, each metal part has been carefully designed and manufactured through sheet metal fabrication. By simulating these tasks during product development, you reduce material usage and can map out your project from start to finish executing tasks cleaner, sharper, and more efficiently.

Ansys Forming equips you with an arsenal of tools within one platform to streamline development, including multistage forming process validation, which offers tool setup and preview; multiple trimming and lancing operations; definition of drawbead, binder force, or spacers; and stamping-specific post-processing tools such as forming limit diagram (FLD) and formability index.

Accelerated simulation time is enabled by a new generation of automatic tool positioning, adaptive remeshing, and massively parallel processing (MPP) technology, which allows you to process larger volumes of data faster.

You also have a material data library at your fingertips with free access to cutting-edge material data upon request from major steel suppliers.

Another advantage in your tool kit — working diligently behind the scenes throughout your project — is the predictive accuracy of Ansys LS-DYNA. The reliable solver offers a wide range of capabilities to simulate and tackle extreme deformation problems — from examining how material failure progresses within one part or an entire system to modeling large amounts of parts or surfaces collectively. This flexibility offers scalability to run even the largest of simulations in a very short amount of time with dependable results.

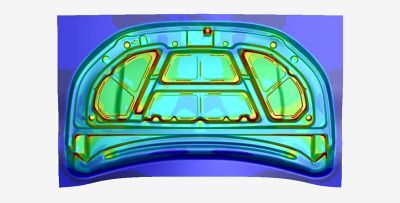

Material flow analysis and simulation in Ansys Forming of the edge of the sheet metal of an automobile fender

“Ansys Forming will meet the metal stamping needs of the industry, from the biggest manufacturers and suppliers to the smallest die shops,” said Shane Emswiler, senior vice president of products at Ansys via a press release. “With all-in-one stamping software, manufacturing and process engineers will streamline their workflows, increase productivity, and achieve consistent solutions every time.”

Of equal importance: Ansys Forming helps you detect errors, identify the most appropriate materials to use, and determine the most efficient and cost-effective machining process for the task at hand. In addition to the clear cost reduction, this minimizes the risk of late-stage redesign.

Industry leaders are already turning to Ansys Forming for faster solutions.

“Ansys Forming is intuitive, efficient, and allows our team to set up complicated forming processes in a short period of time,” said Xue Fei Green, technical director of Dongguan Vision Tool & Mould Co., Ltd. in the press release. “Ansys Forming combines pre- and post-processing in one package and removes a lot of the manual work required by its predecessors. I’ve used many and am confident that Ansys Forming is the best pre- and post-processor for metal forming applications.”

To learn more and discover how to use Ansys Forming to improve your product designs and workflow, register to access the on-demand webinar: Introduction to Ansys Forming.