-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

January 23, 2023

How DYNAmore Will Extend Ansys Automotive Simulation Advances

Many of us will remember the song “Mmm Mmm Mmm Mmm” by a band called the Crash Test Dummies back in the ’90s. Since then, I’ve become a little more familiar with real and simulated crash test dummies, and how their use has radically improved vehicle safety. The recent announcement that Ansys and DYNAmore will become one family is great news. DYNAmore is a very impressive organization, and I’m thrilled that our relationship will be even closer.

The team at DYNAmore have decades of experience in all things Ansys LS-DYNA, in fact they recently celebrated their 20th anniversary. Most people won’t realize it, but there is a very high chance that the car you drive every day is safer because of the work the team at DYNAmore do. Nine out 10 of the largest automotive companies in the world are customers of DYNAmore; that, to me, is just incredible.

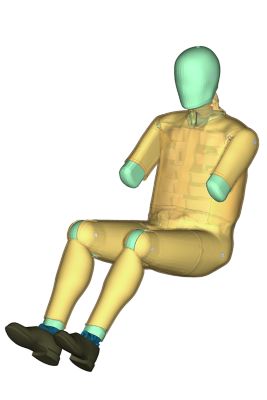

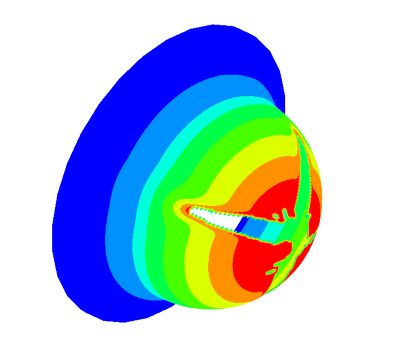

Vehicle safety has benefited hugely from innovations such as crash structure design, the use of different materials, airbags, and consideration of more types of crash, such as the frontal offset test. The development of these technologies would be impractical without simulation. Each crash test, using real cars and physical dummies, is incredibly expensive. You really want to make sure that when you do the physical test, you’re confident that your design is right. Having to build a new car and run the test again costs a lot. Beyond the cost of the car, testing equipment and in-car sensors, a single crash test dummy can cost more than $500,000. (Watch “Why crash test dummies cost $1 million,” CNBC.com)

Experts in Explicit Dynamics

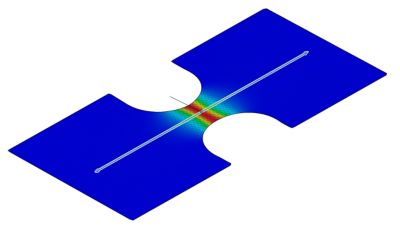

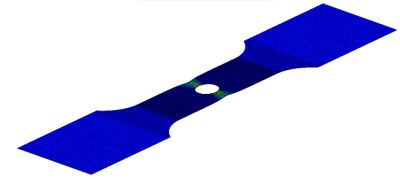

LS-DYNA excels at simulating the response of materials subject to short periods of severe loading, such as those that occur during drops and crashes, even if those crashes are on a smaller scale. It's no secret among my colleagues that I’m a big fan of Lego. The DYNAmore team showed off their LS-DYNA skills when they published this Lego Challenge video comparing physical test vs. simulation. The combination of two of my favorite things — simulation and Lego — pretty cool stuff. The models used are some of the biggest Lego sets available, the Porsche 911 GT3 RS and the Bugatti Chiron, each having thousands of parts.

In the video, you can see how the simulation matches the physical test pretty closely. This obviously was not as critical as a real engineering test where engineers are making decisions that may save lives, but it does do a great job of showing how powerful simulation, and the LS-DYNA solver in particular, can be.

Deep Innovation Across a Broad Array of Industries

Engineers of all types use LS-DYNA to study product behavior via simulations involving severe material deformation or failure. As the Lego video shows, the software makes it possible to study the interaction between parts, enabling users to easily evaluate how parts and assemblies behave together, or how the product behaves as part of a larger system. A bike helmet striking the pavement, a turbine engine containing fragments of a broken blade, or a server crashing to the floor are all examples of real-world interactions that have been studied with LS-DYNA. Severe material deformation behavior could be related to anything from airbags deploying to metal bending during hydroforming. There are thousands of such short-duration events and contacts that could be analyzed using LS-DYNA.

There are many hundreds of customers in varied industries and over 150 universities who benefit from DYNAmore’s knowledge and expertise, especially when it comes to the automotive industry. DYNAmore has offices in six different countries, mainly in Europe, with one office in the US.

We welcome the DYNAmore team to Ansys and look forward to adding their go-to-market and development expertise to our existing sales, engineering, research, and development teams.

Learn more about Ansys LS-DYNA and our range of solutions for the automotive industry.