-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Ansys stellt Studierenden auf dem Weg zum Erfolg die Simulationssoftware kostenlos zur Verfügung.

-

Kontakt -

Karriere -

Studierende und Akademiker*innen -

Für die Vereinigten Staaten und Kanada

+1 844,462 6797

ANSYS BLOG

January 29, 2021

Accelerate Automotive Electronics Design Analysis

Consumers want the latest and greatest automotive electronics that provide enhanced safety, convenience and entertainment. Automakers want to add those features without adding weight to vehicles, which becomes an especially vexing conundrum as the number of automotive electronics multiply via active and passive safety systems, electric propulsion and autonomous vehicle initiatives. As a result, there is a constant push to make electronic components and packages smaller, while increasing performance.

Automotive designers can solve the more electronic functionality in a smaller package dilemma without extending the time it takes to get new cars to market by integrating reliability analysis early in the development process. Automated design analysis software provides fast and accurate life predictions for electronic hardware. It enables designers to model silicon so solder fatigue failures from thermal, mechanical and manufacturing conditions can be predicted. This helps shorten the expensive test-fail-fix-repeat cycle, which accelerates product qualification while reducing manufacturing risks. Ultimately, incorporating reliability physics/physics of failure (PoF) early in the product design and development cycle helps automakers and their suppliers bring new technologies to market faster.

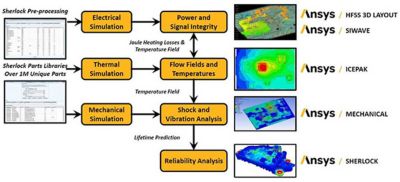

Ansys Sherlock automated design analysis software is a reliability physics/PoF-based electronics design analysis software that provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early design stages. Instead of using statistical models to predict reliability without gaining insight into why something failed, Sherlock’s PoF-based approach uses knowledge and understanding of the processes and mechanisms that induce failure in order to improve product performance. Electrical and mechanical engineers can work in tandem using Sherlock to design for reliability from the start of the project..

Three Steps to Better Electronics Reliability Prediction

Sherlock simplifies and improves reliability prediction using a three-phase process.

1. Data input

With its extensive parts/materials libraries, Sherlock automatically identifies your files and imports your parts list, then builds a finite-element analysis (FEA) model of your circuit board in minutes by automatically parsing standard electronic design automation (EDA) files, such as schematics, layouts and parts lists; using embedded libraries for parts, packages, materials, solders and laminates; and building box-level FEA models.

Ansys Sherlock features embedded, populated and modifiable libraries.

2. Analysis

Sherlock produces a holistic analysis that is critical to developing reliable electronics products. It enables designers to simulate each environment, failure mechanism and assembly that a product might encounter over its lifespan.

Assessment options include:

- Thermal cycling

- Mechanical shock

- Natural frequency

- Harmonic vibration

- Random vibration

- Bending

- Integrated circuit/semiconductor wearout

- Thermal derating

- Conductive anodic filament (CAF) qualification

- High-fidelity PCB modeling

3. Reporting and Recommendations

Data collection is great, but it’s critical that you are able to quickly visualize the data and share it with others inside and outside of your department. Sherlock makes it easy to interpret your data analysis and collaborate. Reporting features include life curves, red-yellow-green risk indicators, tabular and graphical overlay displays, binned results based on reliability goals and automated report generation.

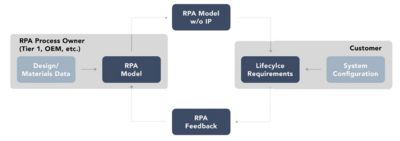

Sherlock also gives you the ability to share a model for review by suppliers or customers that gives them the information they need while locking down your intellectual property. And all of this is done quickly. Sherlock provides near real-time production of custom reports (up to 100+ pages per PCB), plus dataset and image export capabilities.

Sherlock’s Locked IP Model protects intellectual property in the supply chain.

Electronics Reliability: Collaborate and Integrate to Innovate

Sherlock can be used to translate electronic computer-aided design (ECAD) to FEA in minutes, providing the basis for a streamlined product development workflow. Sherlock can be implemented at many stages of a typical design process, from the initial part selection and placement to the final bill of materials (BoM) and layout to design for manufacture (DfM).

You can make Sherlock part of an integrated workflow to assess board-level reliability for accurate product lifetime predictions by connecting it with the complete Ansys ecosystem for electronics reliability. This systems approach enables you to address mechanical concerns, such as shock, drop, vibration and thermal cycling/fatigue; as well as electrical concerns, such as signal integrity/power integrity (SI/PI), electromagnetic interference/compatibility (EMI/EMC) and more.

The Ansys reliability ecosystem

To learn more about Ansys Sherlock, watch this brief introduction video, or get your Sherlock free trial today!