Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

“Sign support, luminaire support, and work zone traffic control device are installed in an extensive array of configurations. Some recent full-scale crash tests involving sign supports resulted in windshield tearing and roof deformation of the test vehicles, which could be potential safety risks. Researchers evaluated design options for improving the crashworthiness of breakaway devices and developing new surrogate testing vehicles to accurately replicate breakaway device behavior with lower-cost components in partnership with Florida Department of Transportation and the National Cooperative Highway Research Board. LS-DYNA from Ansys, Inc. allowed us to arrive at a cost-effective solution and to have confidence that the solution will work for a wide range of systems”

— Cody Stolle, Research Assistant, UNL

Engineers in the Midwest Roadside Safety Facility (MwRSF) at the University of Nebraska-Lincoln develop life-saving devices for use on the sides of the road to protect the occupants of impacting vehicles. Although full-scale crash testing of all roadside hardware is required to demonstrate that occupants will be safe during impacts, simulation enables the faster and less expensive evaluation of unique features of roadside devices and maximize the probability of occupant survival and successful test performance. Simulation also enables researchers to explore impact conditions that could have increased occupant risk but are difficult to test for, such as side impacts and airborne vehicles.

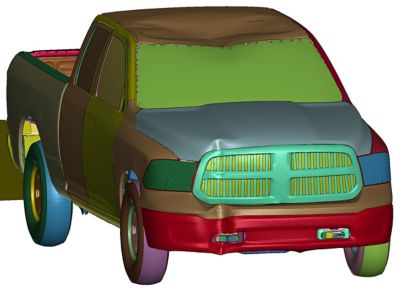

Computer models for slip base sign support

Challenges

Full-scale crash testing is expensive and time-consuming. Often, determination of the most critical impact conditions requires evaluation of many different combinations of parameters such as impact location, speed, and vehicle attitude. Computer simulations are a useful tool for predicting system performance during impact and making improvements before performing a crash test. Simulation software must be capable of reproducing vehicle reactions and occupant risk through nonlinear dynamics, predict fracture and plastic damage to components with multiple types of materials such as timber, steel, and aluminum, and enable researchers to perform parametric studies with different impact conditions. Visualizing simulation results and calibrating simulation data with empirical test results ensures that the best roadside safety products are evaluated in the most critical ways.

Engineering Solution

One example of a simulation-driven research effort includes the evaluation of safe, breakaway sign supports in combination with the Flordia Department of Transportation (DOT) to generate efficient, low-cost, and safe sign supports. Due to the corrosive sea air environment throughout Florida, aluminum sign supports are favored over steel when practical. The research team developed and calibrated sign support models that mimicked sign supports used in full-scale crash tests. Next, the research team investigated breakaway post sizes and heights, sign panel clusters comprised of various individual sign panel shapes and sizes, and cost-effective modifications such as adding masses of various sizes and at various locations to alter post-impact dynamic behavior. Each of these features affected how sign supports reacted after impact, such as the potential for the sign support to impact windshields or roofs and potentially spear into the occupant compartment. Designs were optimized to maximize safety for all road users and finalized recommendations were developed for crash testing.

Comparison of tested and simulated post damage

Benefits

Computer simulation enabled the research team to evaluate many combinations of sign supports and identify which combinations would maximize occupant safety while meeting the DOT needs for information exchange, resistance to wind and weather conditions, and using low-cost, efficient construction techniques. This enabled the rapid evaluation of a large number of potential parameters and minimized the number of full-scale crash tests required to confirm the safety of the sign support design.

Comparison of tested and simulated vehicle damage for new breakaway concept

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.