Quick Specs

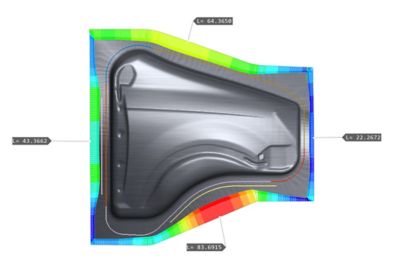

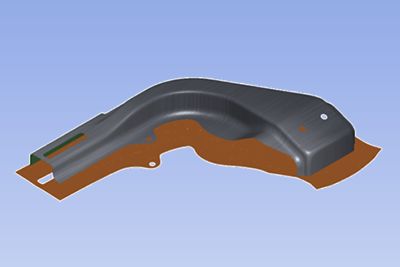

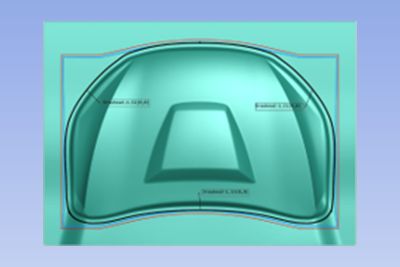

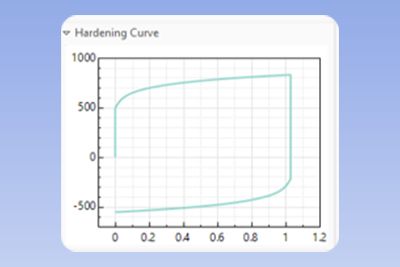

Powered by the LS-DYNA solver, Ansys Forming offers a comprehensive platform to meet all your metal stamping needs. Able to monitor each stage with presets, including feasibility, formability, and springback, Ansys Forming advances early stage and detailed design configurations.