Ansys Rocky

Software di simulazione della dinamica delle particelle

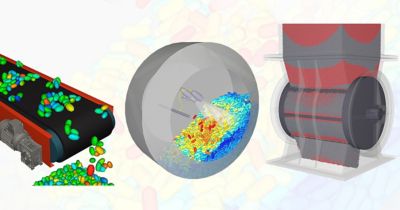

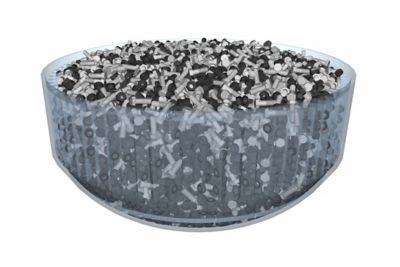

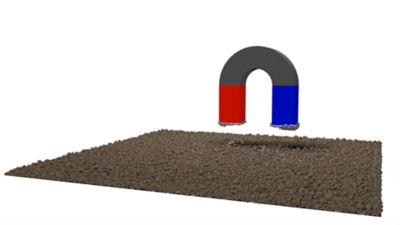

Ansys Rocky è il software leader nel settore dei metodi a elementi discreti (DEM) utilizzato per la simulazione del movimento di materiali granulari e discontinui.

Quickly and Accurately Simulate Particle Flows

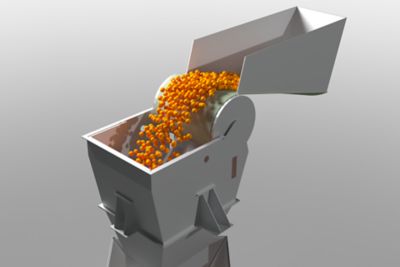

Rocky is designed to solve engineering problems. Rocky is uniquely capable to models real particle shapes including any solids, 2D shells, and rigid and flexible fibers. The simulations are fast and accurate. With multi-graphics processing unit (GPU) solver technology, you can simulate the behavior of different shaped and sized particles in many industrial applications.

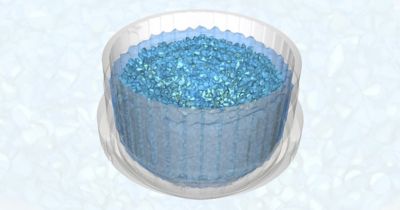

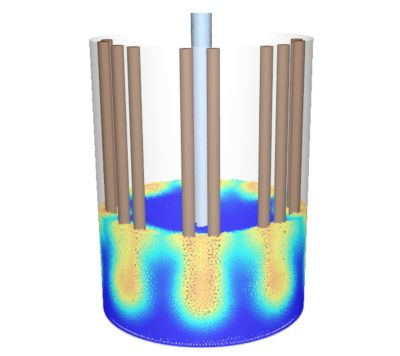

Custom Fitting a Solution for Kitchen Appliances

Using DEM to design a more robust heat exchanger

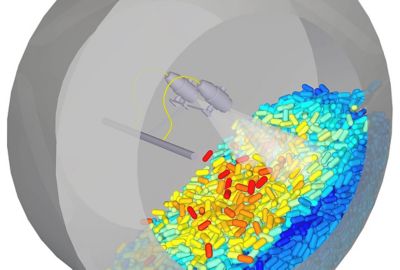

Compared to bench-top component-level testing, overall foulant simulation can produce savings of up to 10% of total development costs — along with reduced time to market, since results are available in a week, compared to months.

Built-in appliances fill today’s high-end kitchens, in which seamless integration with cabinetry can pose technical challenges related to airflow restriction in a machine’s compartment. This problem is exacerbated by dirt accumulation on the condenser (heat exchanger), which can affect appliance performance.

Experimental evaluation of dirt accumulation on condensers is time-consuming and expensive. Consequently, Sub-Zero is coupling Ansys Fluent computational fluid dynamics (CFD) and Ansys Rocky discrete element modeling (DEM) to quickly gain insight on the mechanisms behind dirt accumulation in an effort to design a more robust heat exchanger.

July 2025

What's New

Ansys Rocky 2025 R2 introduces the capability to consider both DEM/SPH forces in two-way structural coupling simulations with Ansys Mechanical. Deformable particles, a beta feature, allow simulation with large elastic and plastic deformation of solid particles. The new DEM Liquid Spray module brings additional physics and is now available to download. The thermal support for semi-resolved cases is present in this latest release.

DEM Simulation

Deformable particles (Beta) enables large particle deformation; EEPA (Edinburgh-Elasto-Plastic-Adhesion) contact model allows tensile adhesive forces between particles under compression; new ready-to-use module DEM Liquid Spray module (Beta) available for download and Material Storage management script (Local / Ansys Granta).

Multiphysics Coupling

Semi-resolved thermal support that couples Rocky-Fluent simulations; 2-Way Structural Coupling with FSI (Fluid-Structure Interaction) where Rocky sends the DEM/SPH forces to Mechanical and Electromagnetic Coupling module Field Modulation enhancement that enables static point clouds to be modulated following a predefined wave shape.

Performance and Usability

Point Cloud support for vectorial properties and usability enhancements, import .msh file as a particle; better performance when loading properties during scripting; coefficients used to calculate drag, lift, and heat transfers are now exposed as particle properties; oriented volumetric inlet.

ROCKY CAPABILITIES

Solve the Largest, Most Complex Particle Simulations With Ease

Ansys Rocky unlocks the potential of solving the most challenging DEM simulations. Large scale simulations, going up to millions of particles, can be solved using real particle shapes on multi GPU’s.

Key Features

Rocky is the premier tool for quickly and accurately simulating the behavior of bulk materials with complex particle shapes and size distributions.

- Multi-GPU Processing

- Realistic, Complex Particle Shapes

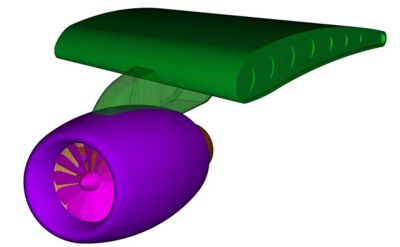

- Fluids Coupling

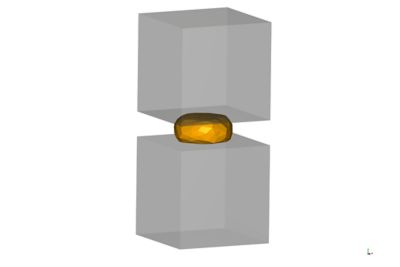

- Structural Mechanics Coupling

- Electromagnetic Coupling

- Multibody Dynamics

- Breakage Modeling

- Smoothed-Particle Hydrodynamics

Featured Webinars

Ansys 2025 R1: Ansys Rocky What’s New

Join us in this webinar to discover all the new features in Ansys Rocky’s 2025 R1 release.

Webinar Series

Ansys Rocky Webinar Series

This webinar series features 15-minute demonstrations showcasing how Rocky can be used to solve some of your most challenging particle simulations.

Ansys 2024 R2: Ansys Rocky What’s New

Join us for this webinar to discover all the new features in Ansys Rocky's 2024 R2 release, including Rocky-Mechanical coupling enhancements, transient point cloud support, and pre and post-processing with Ansys EnSight Integration and IISPH new interface.

Webinars on Demand

Blogs

Case Studies

Ansys software is accessible

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.