Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

“Ansys HFSS software has proven to be a valuable tool in the development of a novel ground-penetration radar inspection methodology for reinforced aerated autoclaved concrete (RAAC) to survey the challenging end-bearing regions of panels as part of our large, publicly funded IUK RAAC IMPACT Program at the MTC. “

— Dr. Joshua Elliott, Technology Manager, M&NDT, The Manufacturing, Technology Centre (MTC)

Ground-penetrating radar (GPR) is often used to survey reinforced concrete beams, but the region supported by a load-bearing wall often cannot be accessed without resorting to destructive methods. Assessing this load-bearing length and identifying rebar locations without causing damage to the plank is crucial. The challenge was set to find a method of surveying this hidden region using GPR. The funding for this work was provided by Innovate U.K. (Project 161047 2023/24 Pulse, MTC RAAC Program).

Challenges

A reliable NDT approach for surveying reinforced aerated autoclaved concrete (RAAC) was required. The Manufacturing Technology Centre (MTC) planned to apply an angled GPR sensor to examine if there was a way to nondestructively survey this hidden load-bearing region. However, the signals gained proved difficult to interpret. Ansys HFSS high-frequency electromagnetic simulation software was used to simulate angled-beam GPR scans, systematically removing specific structural features to identify all the signals present to determine the optimal wedge design and configuration to support successful scan interpretation.

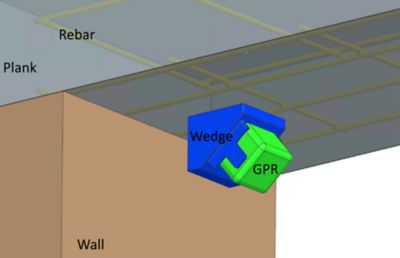

Figure 1. An angled GPR sensor scanning the load-bearing end of a reinforced concrete plank supported by a wall

Engineering Solutions

- The MTC used HFSS software in time-domain reflectometry mode with a modal wave port excitation to simulate a GPR sensor scanning the structure under investigation.

- They then repeated the simulation for multiple sensor positions.

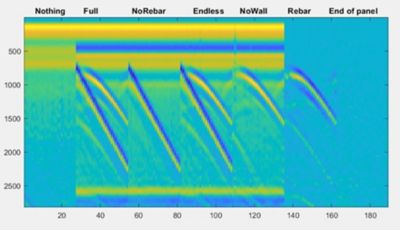

- The MTC plotted the resulting traces as a false color image (using MATLAB) to simulate a standard GPR scan.

- They systematically removed features within the scanned structure to see which responses corresponded to which artifact in the simulated scan.

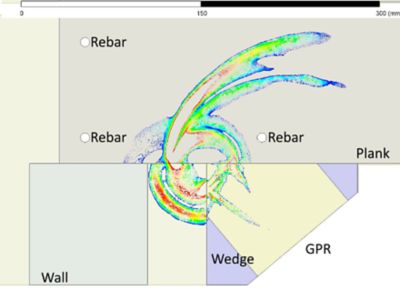

Figure 2. HFSS simulation of electromagnetic waves passing from the wedge into the plank

Figure 3. A false color composite image of simulated GPR scans for different geometric configurations used to identify individual signal components

Benefits

- Problematic and confusing signals were identified by sequentially removing features from the model.

- Methods were derived to either eliminate or control problematic signals.

- The ability of an angled GPR sensor to investigate the load bearing region of a plank was assessed.

- Methods of improving the device were found and implemented.

- The novel application can be extended to other construction installation types.

For further details on the inspection methodology for identification of features within Reinforced Autoclaved Aerated Conrete (RAAC) roofing planks, an open access peer reviewed journal is accessible here.

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.