-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Ansys si impegna a fare in modo che gli studenti di oggi abbiano successo, fornendogli il software gratuito di simulazione ingegneristica.

-

Contattaci -

Opportunità di lavoro -

Studenti e Accademici -

Per Stati Uniti e Canada

+1 844.462.6797

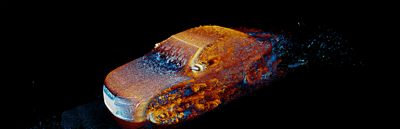

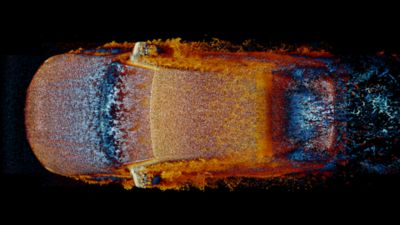

In today’s press release, Ansys announced an exciting milestone in computational fluid dynamics (CFD) simulation achieved in collaboration with NVIDIA and Texas Advanced Computing Center (TACC). This work involved using the 320 NVIDIA GH200 Grace Hopper Superchip nodes on the Vista supercomputer at TACC to run a highly complex automotive external aerodynamics simulation.

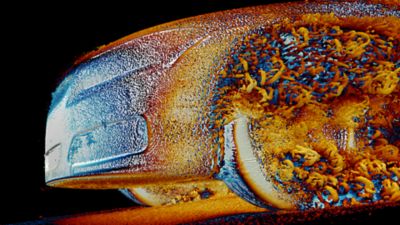

Vista supercomputer at the Texas Advanced Computing Center (TACC)

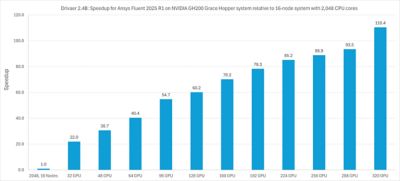

This simulation tackled a 2.4 billion-cell model, achieving extraordinary results, including a 110X speedup over traditional central processing unit (CPU)-based approaches and performance equivalent to more than 225,000 CPU cores. This breakthrough cuts simulation time from nearly a month to just over six hours, redefining the potential for overnight high-fidelity CFD analyses and helping set a new standard in the industry.

Why This Matters: A Revolution in Engineering Simulation

The automotive industry, like many others, faces relentless pressure to innovate and reduce time to market. However, creating realistic aerodynamic simulations with high accuracy is incredibly time-consuming, especially on conventional CPU systems. This latest collaboration among Ansys, NVIDIA, and TACC represents a breakthrough that provides greater speed, cost savings, and insight into product design. For those in engineering and product development, this graphics processing unit (GPU)-driven leap forward offers more than just faster results — it opens the door to simulations of unprecedented scale and complexity that can deliver insights previously out of reach.

Tackling Complex Automotive Aerodynamics Simulations With GPUs

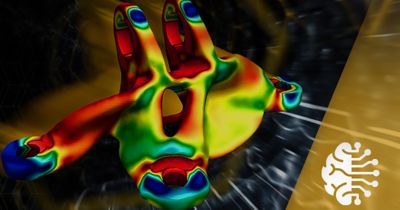

Automotive aerodynamics simulations are among the most complex CFD applications due to their intense computational demands. To accurately simulate airflow over a vehicle’s complex geometry, engineers must use high-resolution meshes, creating tens of millions, or sometimes billions, of cells. These ultrafine resolutions are essential for capturing transient and turbulence physics with accuracy, but they result in significantly longer solve times and increased power requirements when run on traditional CPU hardware.

Our recent simulation on TACC’s 320 NVIDIA GH200 nodes showed that GPUs can handle these immense workloads efficiently, delivering accurate results with far less computing time. For engineers, this translates into two powerful advantages:

- Reduced time to solution with higher-quality products. What used to take weeks can now be completed in hours, enabling faster design variations and shorter product development cycles.

- High-fidelity insight. With NVIDIA accelerated computing, engineers can increase model complexity — such as tackling scale-resolving turbulence models — without increasing solve times, providing more accurate and realistic results to inform product development.

Impact on Customers: Addressing Core Challenges

Time Efficiency

Complex automotive simulations traditionally require long solve times, sometimes taking weeks on on-premises CPU hardware. For customers, this delays the research and development (R&D) process, slowing time to market. By adopting GPUs, automotive engineers can reduce simulation time drastically, enabling them to make design adjustments faster, thus accelerating product development cycles. This GPU-based speed boost can mean the difference between launching on time and losing market share.

Cost Savings

CPU-based simulations are not only time-intensive but power-intensive, increasing operational costs through high energy consumption and cooling requirements. With the efficiency of GPUs, customers can achieve similar or even better results with far less hardware, meaning lower power costs and fewer physical resources. While upfront GPU investments may appear costly, the reduction in energy and engineering costs can quickly offset the expense, making this technology both a short-term and long-term win.

Enhanced Accuracy and Detail

Hardware limitations often force engineers to simplify their models to achieve results in a reasonable time frame, which can compromise accuracy. With the processing power provided by GPUs, customers are no longer constrained by these limitations. They can simulate highly detailed models without extending the solve time, delivering results that are as accurate and realistic as possible. This ability to model at a high level of fidelity ultimately improves the quality, performance, and robustness of the final product.

Looking Beyond the Industry

For those outside the immediate field of automotive simulation or high-performance computing (HPC), this achievement signals the ongoing evolution of technology that impacts a range of sectors. Here’s why this breakthrough matters beyond Ansys’ immediate circle of customers:

- Pushing the boundaries of product development. The collaboration among Ansys, NVIDIA, and TACC is helping to redefine what’s possible in simulation and setting new standards for speed and fidelity. This milestone shows that high-fidelity simulations no longer need to be constrained by hardware limitations, enabling more ambitious and innovative product development.

- Advancing GPU computing capabilities. By demonstrating the scalability of Ansys’ software with NVIDIA accelerated computing, this project highlights the role of GPU computing in making complex simulations accessible and practical. This sets a benchmark that other industries, from aerospace to energy, can use to accelerate their own product innovation.

- Delivering sustainable, cost-effective simulation. This collaboration between Ansys and NVIDIA also underscores the efficiency of GPU computing. Not only does this approach save time and costs — it reduces power consumption, contributing to more sustainable business practices. With every improvement in GPU technology, industries can achieve higher performance with fewer resources, a trend that benefits both companies and the environment.

- Demonstrating Ansys’ commitment to simulation excellence. This groundbreaking simulation underscores Ansys’ commitment to pushing HPC forward. By delivering scalable, high-performance GPU computing solutions, we’re helping organizations maximize their hardware investments and make high-fidelity simulation a feasible option, not just a luxury.

Accelerating Innovation With Ansys and NVIDIA Accelerated Computing

The results of this landmark collaboration among Ansys, NVIDIA, and TACC are transformative. By achieving a 110X speedup using 320 GPUs, this automotive aerodynamics simulation sets a new benchmark for what’s achievable in CFD. With faster times to solution, lower costs, and the ability to model with unprecedented detail, our GPU-powered solutions empower customers to design better products and bring them to market faster.

As we continue to evolve our GPU capabilities, Ansys is committed to equipping organizations with the tools they need to tackle their most challenging simulations. Through this latest work, we are advancing the limits of engineering and transforming the future of product development. This is just the beginning of what GPU computing can achieve for the automotive industry — and beyond.

If you’re ready to take your simulations to the next level, make sure to join us at Supercomputing 2024 (SC24) in Atlanta from Nov. 17 to 22 or download this e-book to discover how to speed up your multiphysics simulations with NVIDIA accelerated computing.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.